Conductive polyaniline gel preparation methods and application of same to supercapacitor

A technology of conductive polyaniline and polyaniline gel, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, and can solve problems affecting the transmission of conductive polymer materials, reducing the specific surface area of gels, and affecting electrochemical performance. , to achieve obvious redox performance, no environmental pollution, good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

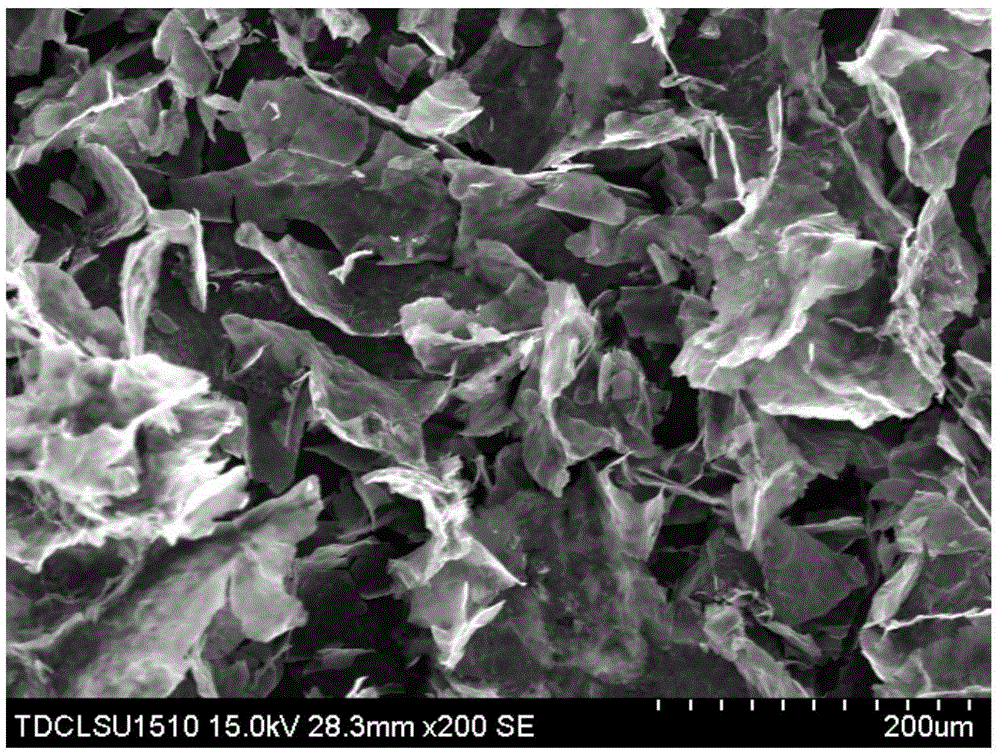

[0031] Dissolve 2mmol of aniline and 1mmol ATMP in 1mL of distilled water, stir ultrasonically for 30min to fully dissolve and mix, then place it in an ice-water bath at 0°C; dissolve 0.1g of ammonium persulfate in 0.5mL of distilled water, then place at 0°C In an ice-water bath; finally, quickly add the solution containing ammonium persulfate to the solution containing aniline and ATMP, ultrasonically for 10 seconds, and then let it stand for 10 minutes to form a polyaniline gel, which is then washed 2-3 times with distilled water; The polyaniline gel was freeze-dried to obtain the product. The prepared conductive polyaniline gel was analyzed by scanning electron microscope (SEM), such as figure 1 As shown, it can be seen that the gel is a three-dimensional network porous structure composed of nanosheets, and the nanosheets are connected to each other. The electrical conductivity of the lyophilized polyaniline gel measured by a four-probe resistivity tester was 0.31 S / cm, wh...

Embodiment 2

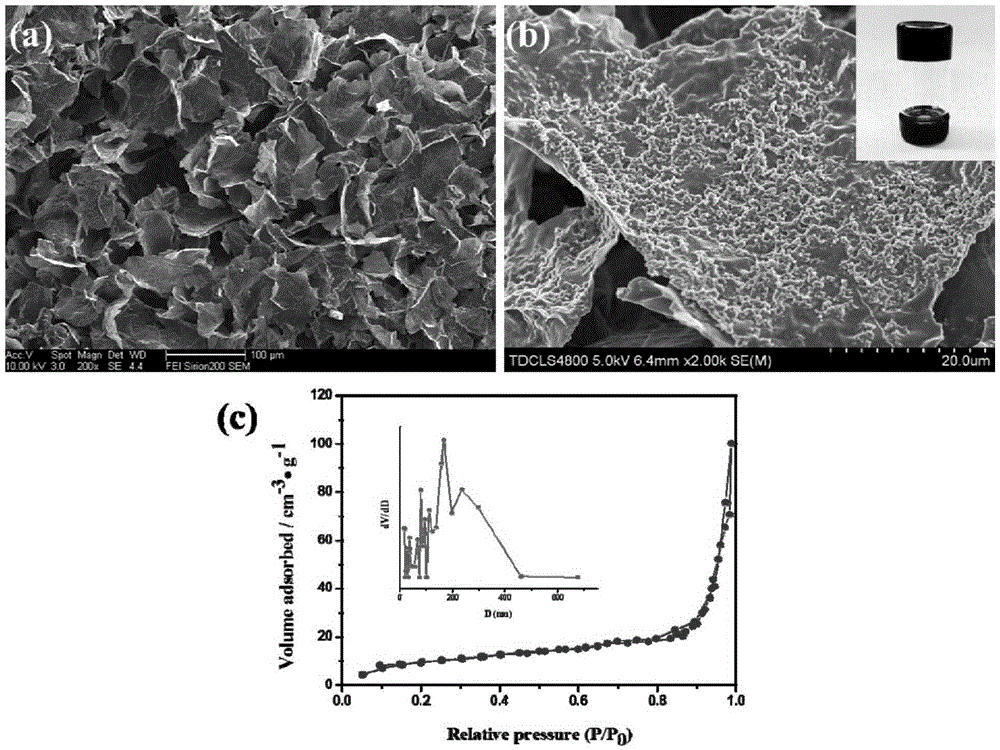

[0033] Dissolve 4 mmol of aniline and 3 mmol of ATMP in 2 mL of distilled water, stir ultrasonically for 30 min to fully dissolve and mix, and then place it in an ice-water bath at 2 °C; dissolve 0.25 g of ammonium persulfate in 1 mL of distilled water, and then place it on ice In a water bath; finally, quickly add the solution with ammonium persulfate into the solution with aniline and ATMP, and put it aside for 30 minutes after ultrasonication for 15s to form a polyaniline gel, which is then washed with distilled water for 2-3 times; the above-prepared The polyaniline gel was freeze-dried to obtain the product. The conductive polyaniline gel that makes is analyzed by SEM and specific surface area (BET), as figure 2 As shown, the polyaniline gel is a three-dimensional network porous structure composed of interconnected nanosheets, the thickness of the nanosheets is about 60 nm, and a large number of micropores are evenly distributed on the nanosheets. The specific surface a...

Embodiment 3

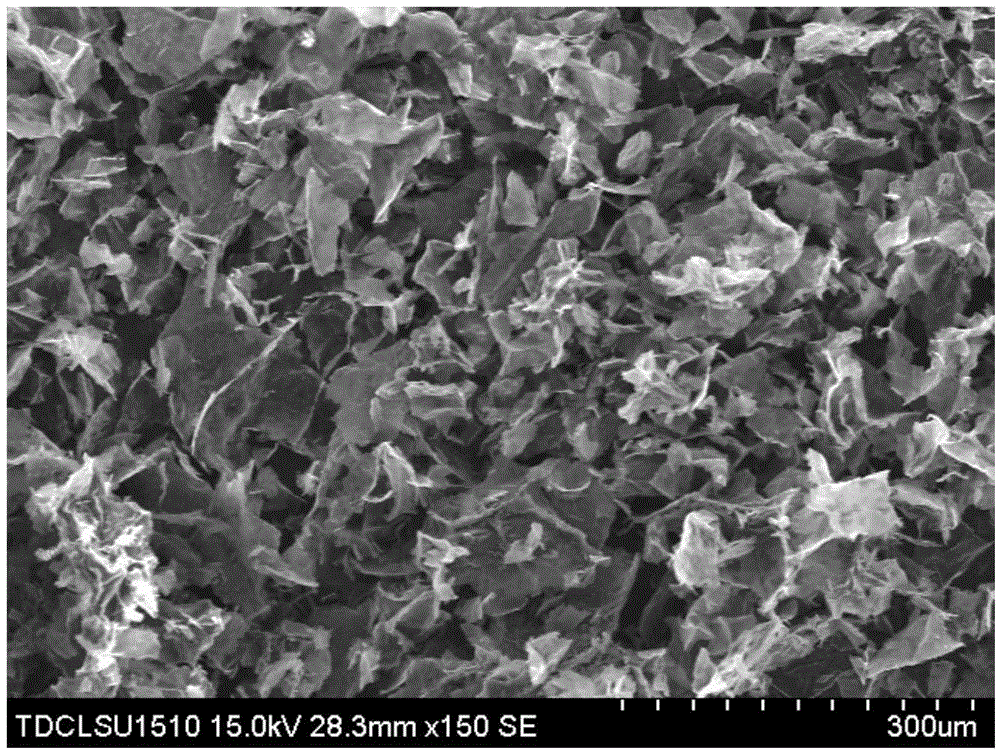

[0035] Dissolve 6mmol of aniline and 5mmol ATMP in 4mL of distilled water, stir ultrasonically for 30min to fully dissolve and mix, then place it in an ice-water bath at 4°C; dissolve 0.5g of ammonium persulfate in 3mL of distilled water, then place on ice In a water bath; finally, quickly add the solution with ammonium persulfate into the solution with aniline and ATMP, and put it aside for 60 minutes after ultrasonication for 30 s to form a polyaniline gel, which is then washed 2-3 times with distilled water; the above-prepared The polyaniline gel was freeze-dried to obtain the product. The prepared conductive polyaniline gel was analyzed by SEM, as image 3 As shown, the gel is still a three-dimensional structure composed of nanosheets. The conductivity of the lyophilized polyaniline gel was measured by a four-probe resistivity tester to be 0.35 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com