Water-soluble cutting fluid

A cutting fluid, water-soluble technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of uneven products, unsatisfactory lubricating effect, non-biodegradable, etc., to reduce the comprehensive use cost and good waste liquid treatment performance , Highlight the effect of anti-corruption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

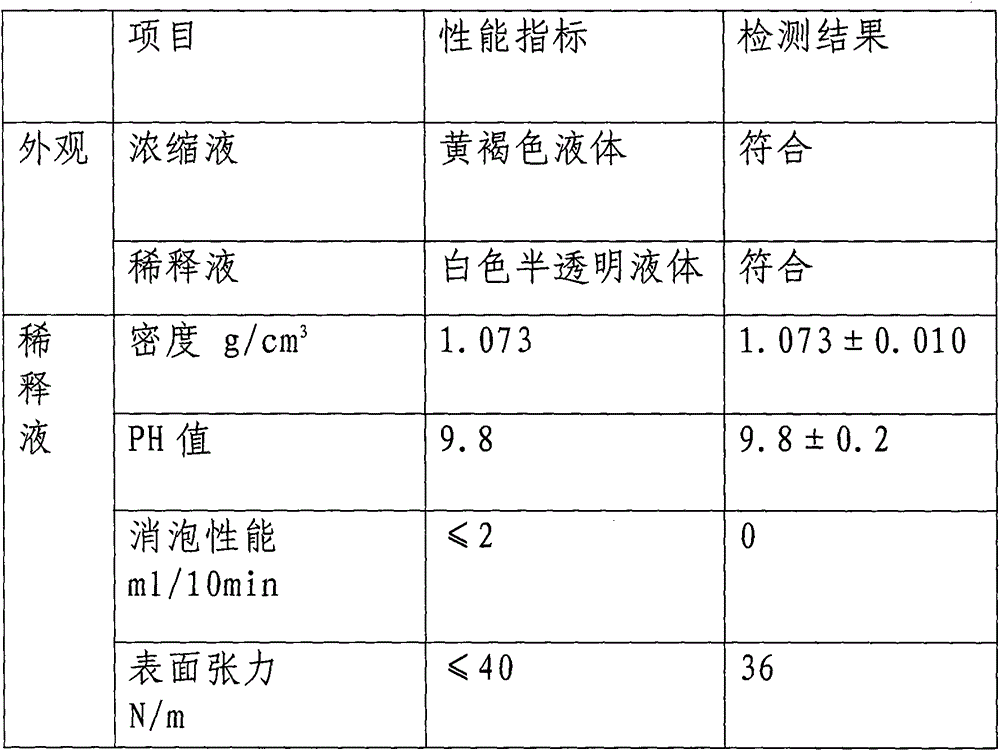

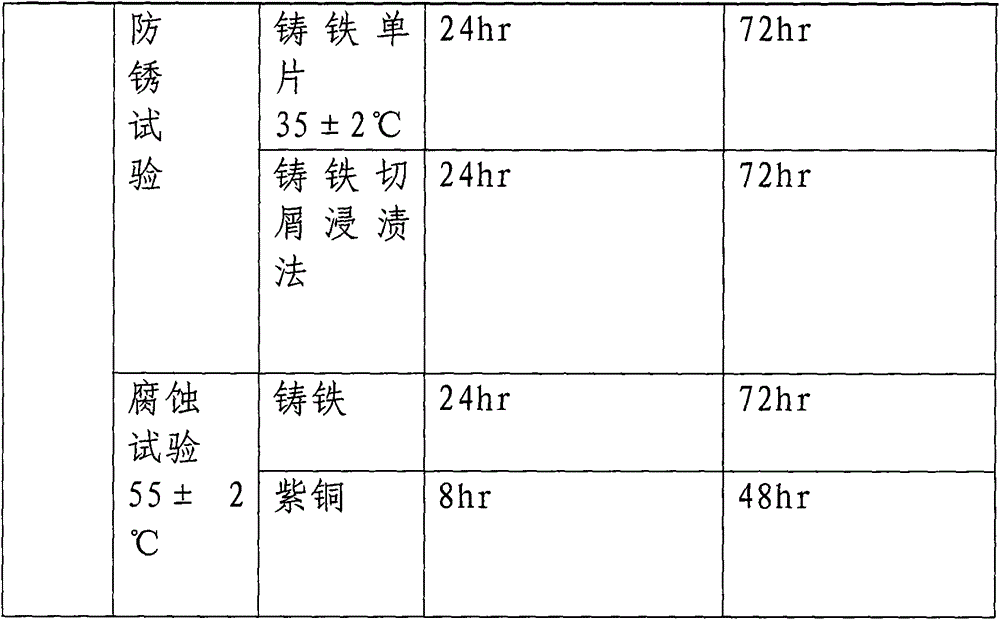

Examples

Embodiment 1

[0029] In this embodiment, a water-soluble cutting fluid contains the following components by weight:

[0030] Coconut oil 8-9, sorbitol 8-9, polyethylene glycol 13-15, dodecanedibasic acid 3-5, boric acid 3-5, benzotriazole 0.1-0.2, ricinoleic acid 2-3 , Tetrameric ricinoleic acid 8-15, DIACID15503-5, sodium gluconate 2-3, alkyl glycoside 2-3, protease 2-4, fungicide 0.3-0.8, defoamer 0.1-0.2, balance water.

[0031] The molecular weight of polyethylene glycol is 400-1000, preferably polyethylene glycol 400. The bactericide is selected from one or more of BK, MBM, ethylene glycol dimethyl ether, isothiazolone, and sodium pyridine sulfate. The defoamer is selected from one or both of GPE type and GPES type polyether defoamers.

Embodiment 2

[0033] In this embodiment, a water-soluble cutting fluid contains the following components by weight:

[0034] Coconut oil 8.15, sorbitol 8.25, PEG40013.6, dodecane dibasic acid 3.64, boric acid 3.64, benzotriazole 0.1, ricinoleic acid 2.73, tetrameric ricinoleic acid 10, DIACID15503.64, sodium gluconate 2.73 , Alkyl glucoside 2.27, protease 2.73, BK0.5, defoamer 0.15, the balance of water.

[0035] Take respectively 30% of the total amount of coconut oil, sorbitol, polyethylene glycol and water according to the above parts by weight, add the obtained coconut oil, sorbitol and polyethylene glycol into water successively, heat while stirring, and the temperature reaches 75°C When the heating is stopped, the reaction product A is obtained;

[0036] Take dodecanedibasic acid, boric acid, and benzotriazole respectively according to the above parts by weight, add them to reaction product A in sequence, stir for 20 minutes, and control the temperature at 60° C. to obtain reaction p...

Embodiment 3

[0041] In this embodiment, a water-soluble cutting fluid contains the following components by weight:

[0042] Coconut oil 9, sorbitol 9, PEG40013, dodecanedibasic acid 3, boric acid 5, benzotriazole 0.1, ricinoleic acid 3, tetrameric ricinoleic acid 15, DIACID15505, sodium gluconate 3, alkyl glycosides 3. Protease 2, BK0.5, defoamer 0.1, the balance of water.

[0043] Get respectively 40% of coconut oil, sorbitol, polyethylene glycol, water total amount according to above-mentioned weight portion, coconut oil, sorbitol, polyethylene glycol that will obtain are added into water successively, heat while stirring, and temperature reaches 75 ℃ When the heating is stopped, the reaction product A is obtained;

[0044] Take dodecanedibasic acid, boric acid, and benzotriazole respectively according to the above parts by weight, add them to reaction product A in sequence, stir for 20 minutes, and control the temperature at 65° C. to obtain reaction product B;

[0045] Take ricinolei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com