Oxidized graphene doped nano-fibers, as well as preparation method and application thereof

A nanofiber and graphene technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of patients' pain, reduce manufacturing costs, promote stem cell differentiation, and achieve good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Another aspect of the present invention provides a method for preparing the aforementioned scaffold material, which may include: taking a spinning solution containing poly(lactic-co-glycolic acid) and graphene oxide and subjecting it to an electrospinning process to obtain the nanofiber scaffold material.

[0048] In a preferred solution, the spinning solution contains polylactic acid glycolic acid at a concentration of 10wt% to 20wt%, graphene oxide with a content of 0.1wt% to 5wt% of the polylactic acid glycolic acid content, and volatile and A solvent with good solvency for polylactic-glycolic acid.

[0049] Further, the solvent used in the spinning solution can be selected and is not limited to tetrahydrofuran and / or dimethylformamide, and through a large number of experimental verifications, the inventors of the present case found that when the solvent of tetrahydrofuran and dimethylformamide is selected When mixed solvents are used as solvents, pure PLGA nanofiber...

Embodiment 1

[0058] 1. Preparation of PLGA electrospinning solution doped with graphene oxide

[0059] Prepare 15% and 18% PLGA electrospinning solutions, weigh 1.8 grams of PLGA powder with an electronic balance and dissolve them in 12 milliliters and 10 milliliters of tetrahydrofuran / dimethylformamide with a volume ratio of 3:1 in a mixed solvent to prepare Concentration is 15wt% and 18wt% PLGA spinning solution, 4 ℃ stands overnight, obtains uniform PLGA solution, standby;

[0060] Weigh 18 mg of graphene oxide powder with an electronic balance and add it to the prepared PLGA spinning solution with a concentration of 15wt% and 18wt%, and stir magnetically for more than 24 hours to make graphene oxide uniformly dispersed in the PLGA spinning solution. Sonicate for 30 minutes before use to remove air bubbles.

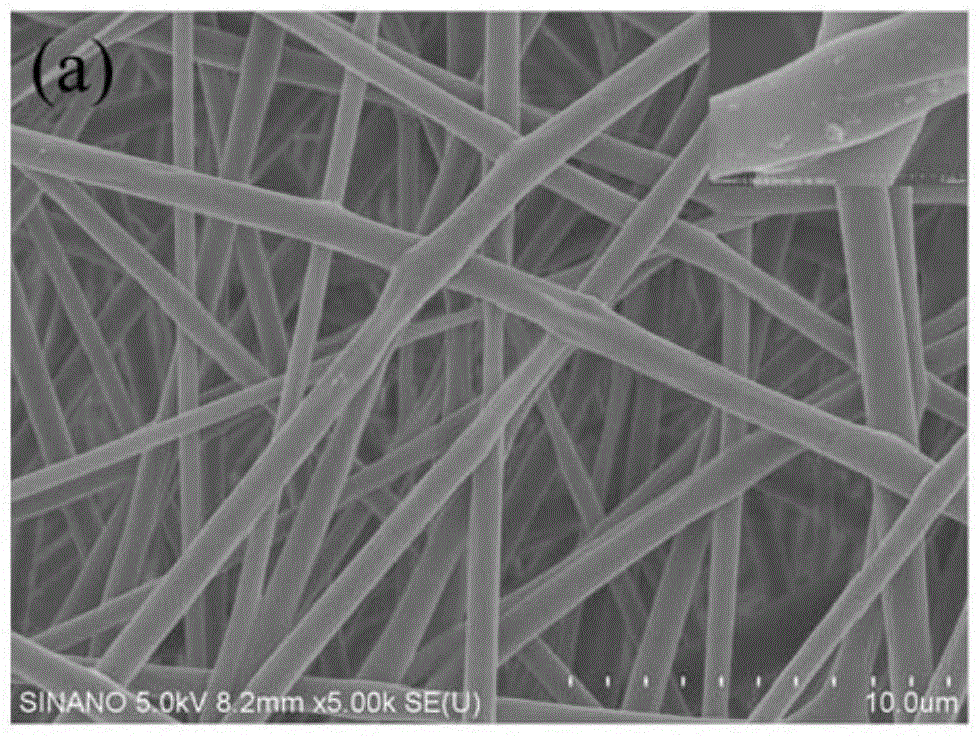

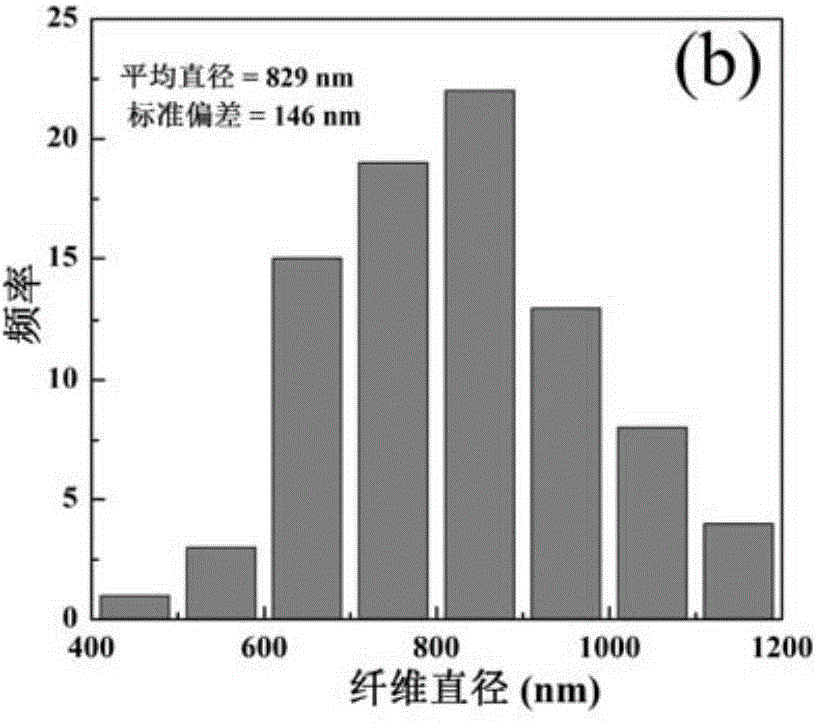

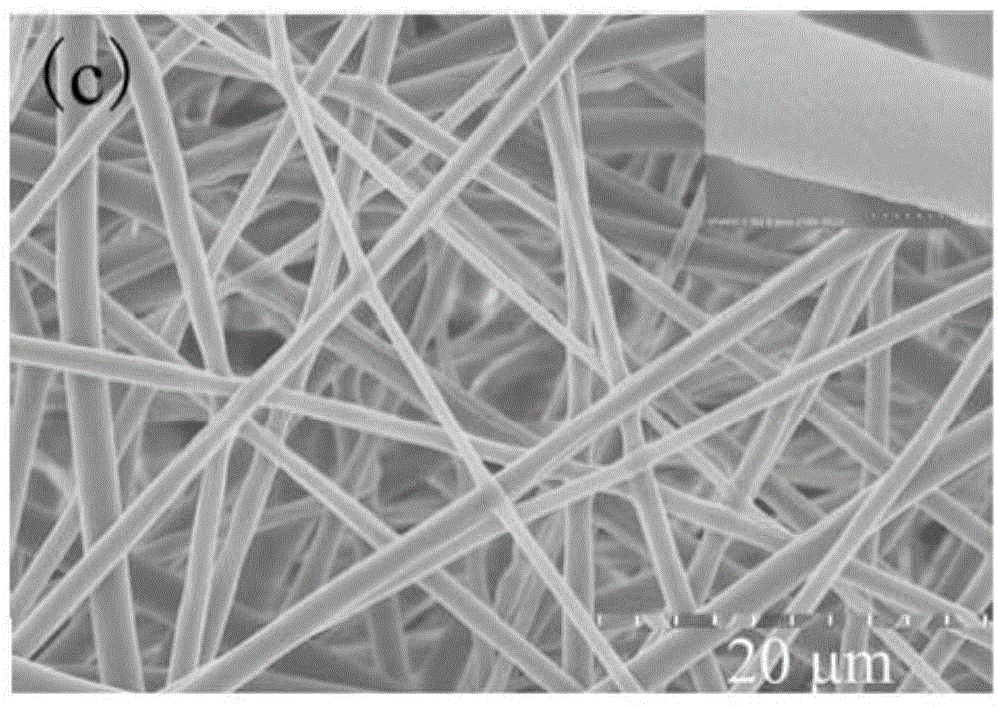

[0061] 2. Preparation of doped graphene oxide electrospun PLGA nanofibers

[0062] Four freshly prepared PLGA electrospinning solutions doped with graphene oxide (15wt% and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com