A new type of large-diameter semiconductor chip and molybdenum sheet bonding ohmic contact processing method

A technology of ohmic contact and processing method, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the deterioration of electrical characteristic parameters, change the PN junction depth and surface concentration distribution, and have large contact transient thermal resistance and other issues, to achieve the effect of improving consistency and yield, improving reverse blocking characteristics, and improving flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

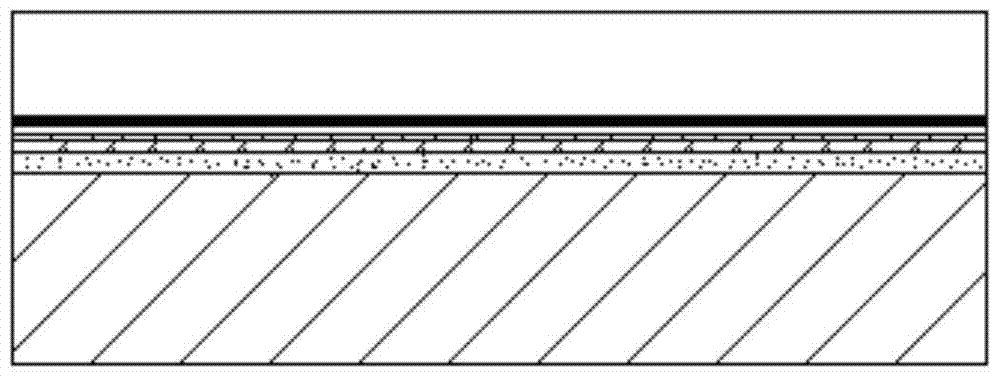

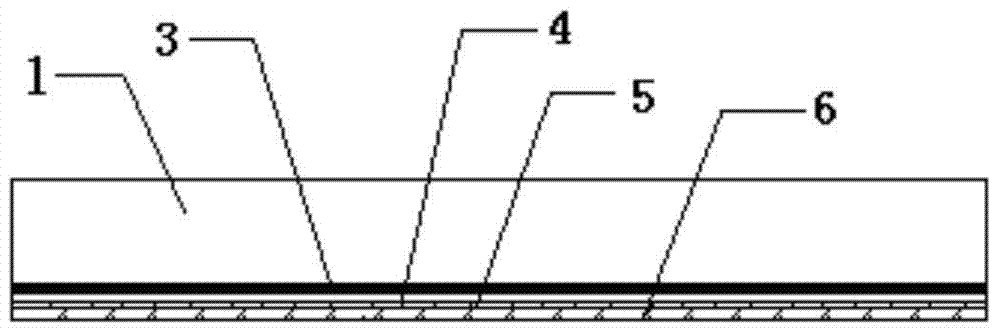

[0028] A new type of large-diameter semiconductor chip and molybdenum sheet bonding ohmic contact processing method, including semiconductor chip 1, molybdenum sheet 2, and the contact layers between semiconductor chip 1 and molybdenum sheet 2 respectively have Al electrode layer 3, Ti / Pt / Au Metal transition layers 4, 5, 6, Ag layer solder layer 7, immerse the semiconductor chip 1 with a 10 μm AL layer 3 on the anode steamed into dilute hydrofluoric acid with a volume ratio of 1±0.5% and the composition is ammonia water: hydrogen peroxide: pure water volume ratio 1:2:5 cleaning solution 1#, then put it in a clean oven and dry it at 100±2℃. Go through the following steps in order:

[0029] First, when the vacuum degree is higher than 1×10 -5 Pa, at a temperature of 100±2°C, bombard the Ti source in the crucible with an electron beam above 10000EV (electron volts), so that the Ti source is excited into a gaseous state, which is evenly distributed in the evaporation chamber in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com