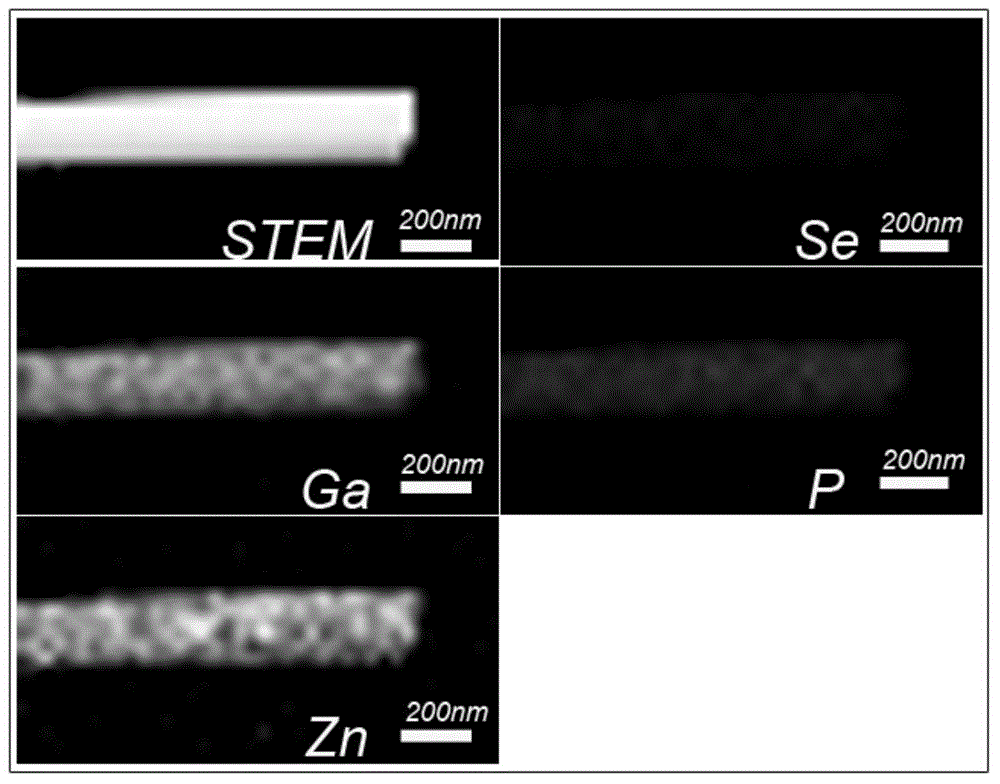

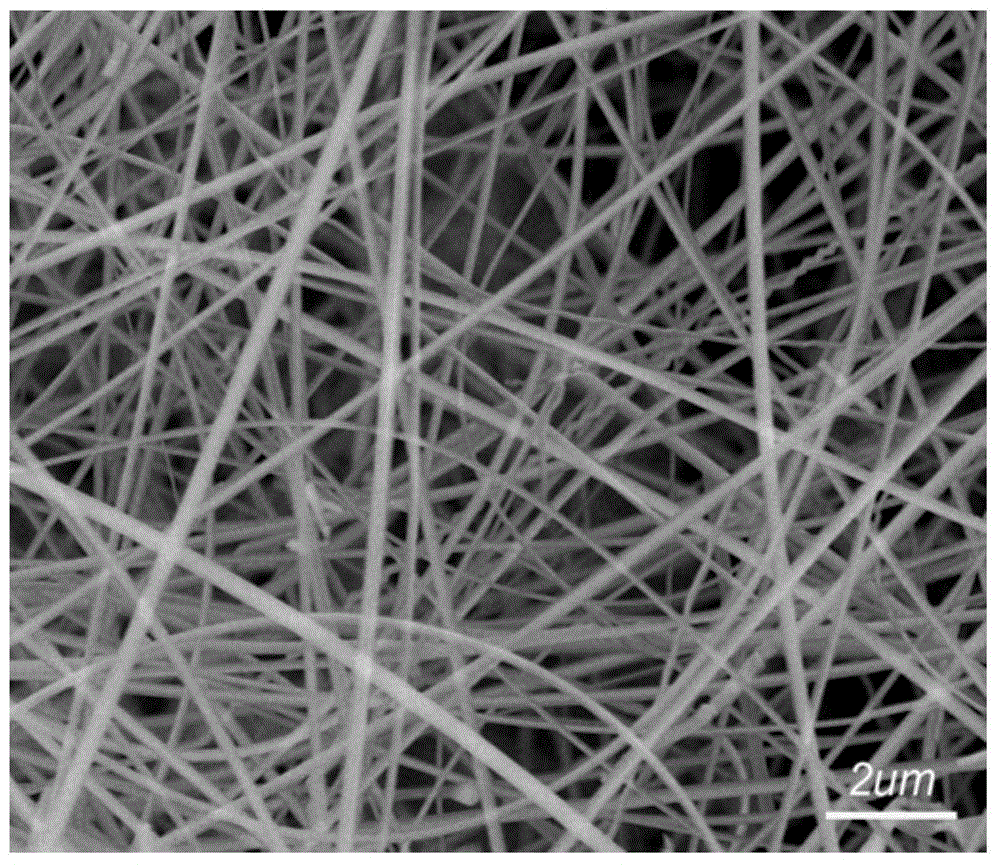

ZnSe-GaP solid solution nanometer material and preparation method thereof

A nanomaterial and solid solution technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficulty in the preparation of multi-component solid solution nanowires, and achieve process parameters that are easy to control and easy to obtain. , the effect of high growth yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment ZnSe-GaP solid solution nanomaterial is prepared by the following process:

[0030] 1. Weigh a certain mass of zinc selenide and gallium phosphide powder (any molar ratio is acceptable), and place them in two porcelain boats respectively. Then weigh a small amount of zinc powder and selenium powder according to a molar ratio of 1:1, and the molar ratio of the two to the zinc selenide powder is 1:10, and put them in a porcelain boat filled with zinc selenide and mix them evenly.

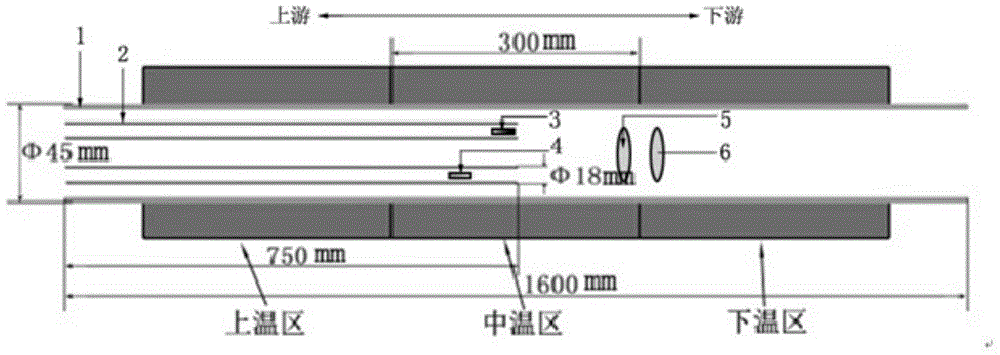

[0031] 2. According to Figure 4 Arrangement method Put the two porcelain boats in step 1 into two small quartz tubes respectively, and put the two small quartz tubes into the large quartz tube together, and place the three quartz tubes in parallel with the nozzles in the same direction. Put the large quartz tube into the three-temperature-zone tube furnace, adjust the position of the porcelain boat, so that the porcelain boat with gallium phosphide is placed in the heat...

Embodiment 2

[0038] The present embodiment ZnSe-GaP solid solution nanomaterial is prepared according to the following steps:

[0039]1. Weigh a certain mass of zinc selenide and gallium phosphide powder (any molar ratio is acceptable), and place them in two porcelain boats respectively. Take zinc powder and selenium powder again, the mol ratio of zinc powder and selenium powder is 5:1, and the mol ratio of selenium powder and zinc selenide powder is 3:10, put in the porcelain boat that holds zinc selenide and mix uniform.

[0040] 2. Put the two porcelain boats in step 1 into two small quartz tubes respectively, and put the two small quartz tubes into the large quartz tube together, and place the three quartz tubes in parallel with the nozzles in the same direction. Put the quartz tube into the three-temperature zone tube furnace, adjust the position of the porcelain boat, so that the porcelain boat with gallium phosphide is in the heating center of the middle temperature zone of the tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com