Full-fluorescence white light organic light-emitting diode and preparation method thereof

A light-emitting diode, full-fluorescence technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of unsatisfactory quantum efficiency and color rendering index, poor performance, etc., to reduce material costs, high luminescence Efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

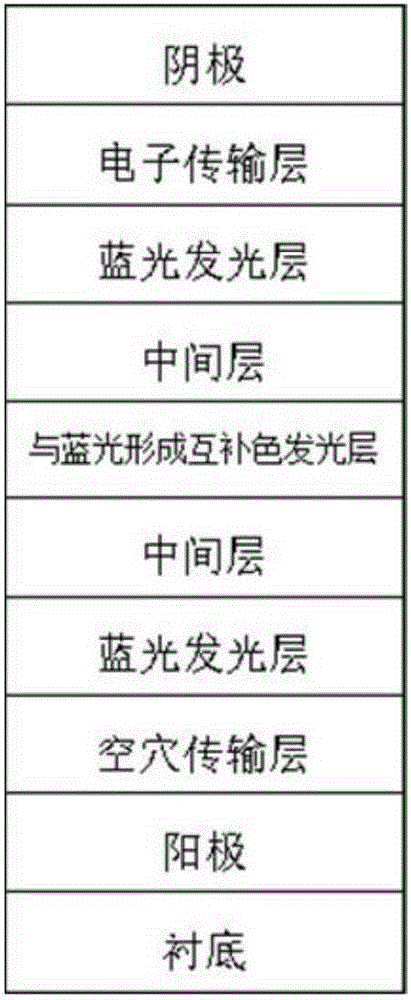

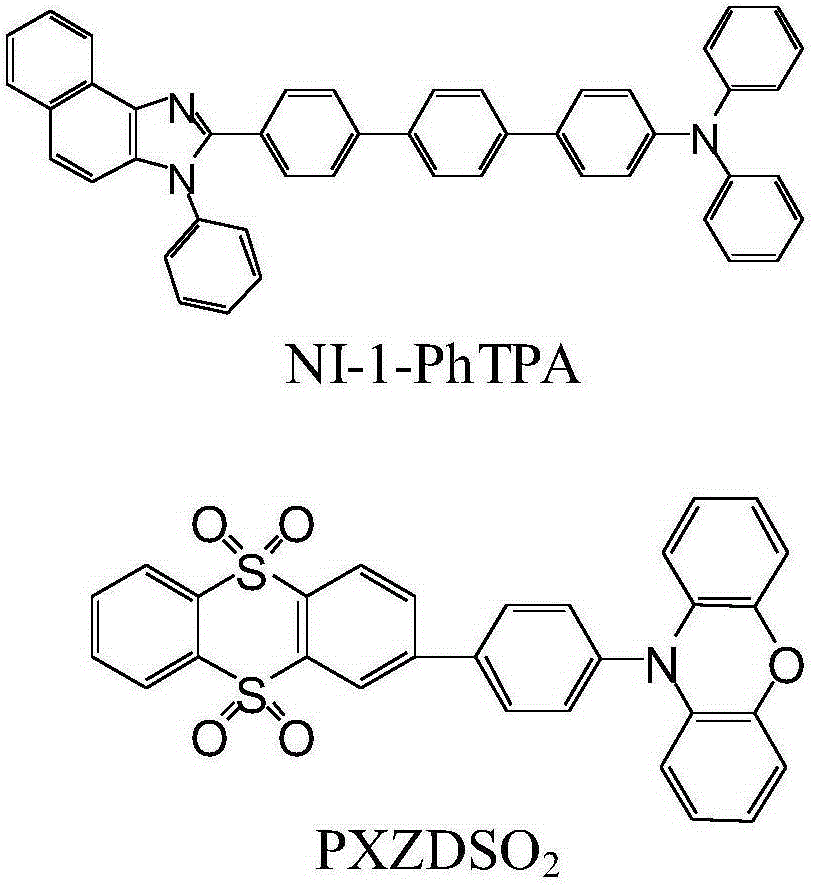

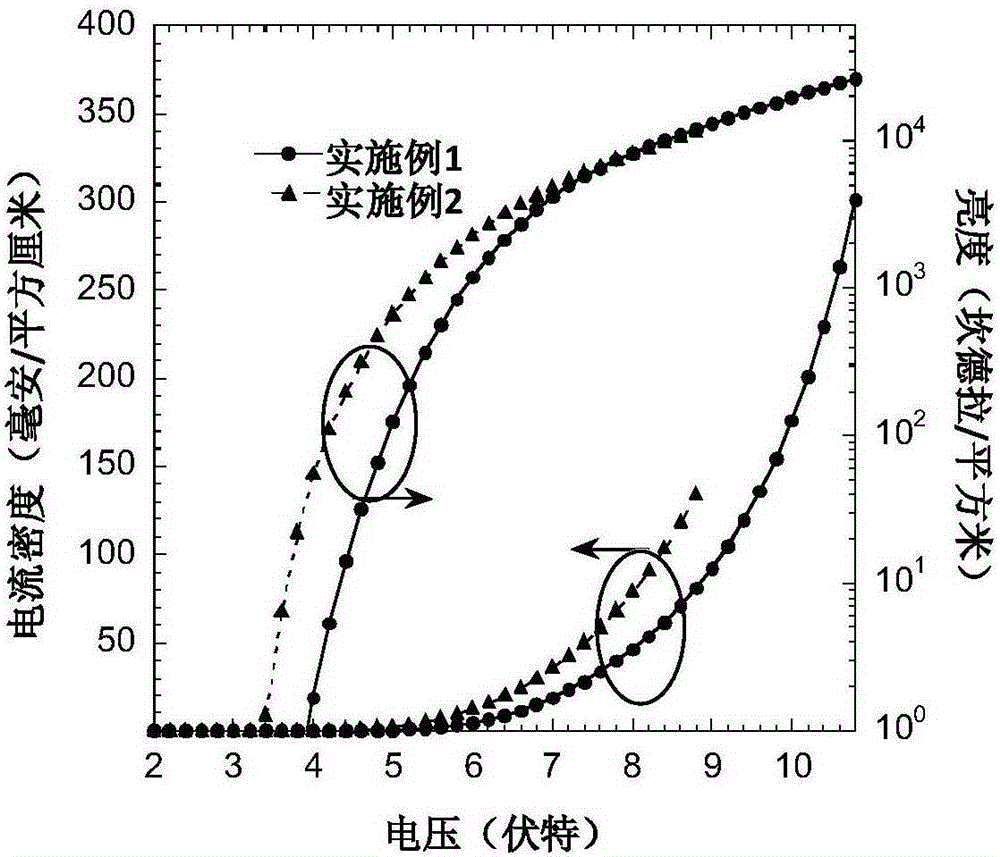

[0035] Take a number of ITO conductive glass substrates with the same batch number, the size is 30 mm × 30 mm, the thickness of ITO is about 90 nanometers, and its square resistance is about 20 ohms / square. Sequentially use acetone, special detergent for micron semiconductors, deionized water, and isopropanol to ultrasonically clean for 15 minutes to remove dirt on the surface of the substrate. Then put it into an incubator to dry at 80 degrees Celsius. The dried ITO substrate was treated with a plasma (plasma) ignition device for 4 minutes to further remove organic impurities attached to the surface. Then the ITO substrate was transferred to a glove box filled with high-purity nitrogen gas without water and oxygen. In this glove box, the devices are loaded into the vacuum plating chamber. Turn on the mechanical pump and molecular pump, when the vacuum in the plating chamber is less than 5×10 -4 The thermal evaporation film starts after Pa. Using a specific mask, sequentia...

Embodiment 2

[0042] The preparation process was the same as in Example 1, and the anode buffer layer material HAT-CN, the hole transport layer material TAPC, the blend of the deep blue fluorescent light-emitting layer material CBP and 10wt% NI-1-PhTPA were evaporated sequentially (CBP: 10wt% NI- 1-PhTPA), intermediate layer material CBP, and blue light to form a complementary color light-emitting layer material is CBP and 5wt% PXZDSO 2 and 0.35 wt% DBP(5,10,15,20-tetraphenylbisbenzo[5,6]indeno[1,2,3-CD:1',2',3'-LM], dibenzo{ Blend of [f,f']-4,4',7,7'-tetraphenyl}diindeno[1,2,3-cd:1',2',3'-lm]perylene) (CBP:5wt% BYZGR 2: 0.35wt% DBP), intermediate layer material CBP, dark blue fluorescent light emitting layer is a blend material CBP: 10wt% NI-1-PhTPA, electron transport layer material TmPyPB, cathode buffer layer material lithium fluoride, cathode material metal aluminum. The evaporation rate and thickness of each functional layer to be evaporated are monitored in real time by a quartz cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com