Micro-arc oxidation method for surfaces of copper, copper alloy, zinc and zinc alloy

A technology of micro-arc oxidation and copper alloy, which is applied in the field of electrochemistry, can solve the problems of poor wear resistance of the film layer and poor adhesion of the substrate, and achieve the effects of enhanced corrosion resistance, enhanced wear resistance, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

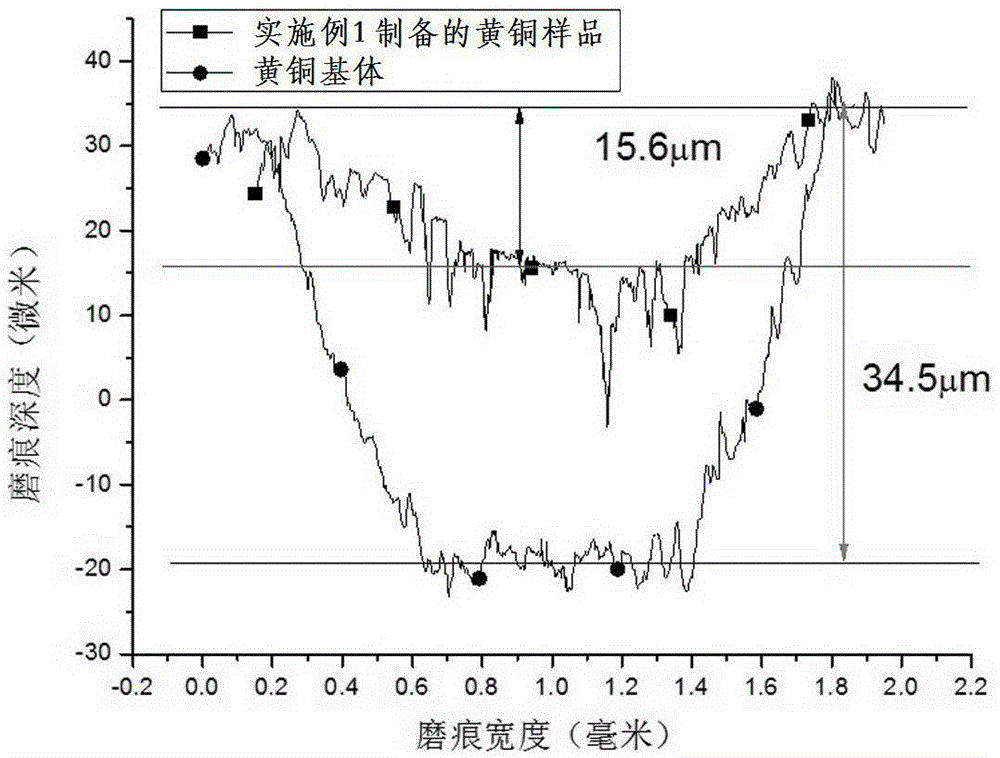

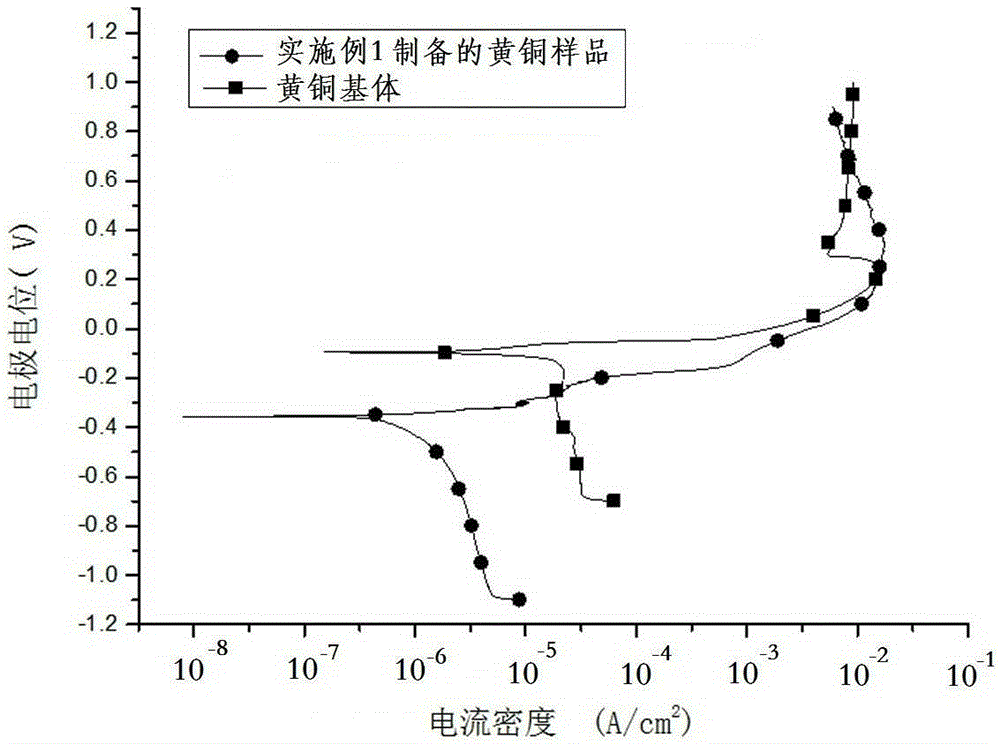

[0027] Embodiment 1: After the brass is polished, a pure aluminum film of about 40 microns is formed by magnetron sputtering. After being sealed with epoxy resin, the brass is placed in a concentration of 32g / L sodium aluminate plus 1g potassium hydroxide , set the electrolysis parameters to positive current 0.6A / cm 2 Negative current is 0.5A / cm 2 , the positive and negative duty cycle is 20%, and the frequency is 1000Hz. After sputtering a pure aluminum film, the brass is used as the anode, and the steel plate is used as the cathode. After 5 minutes of reaction, a dense wear-resistant aluminum oxide ceramic film can be formed on the surface of the brass to obtain a brass sample.

[0028] The brass sample that embodiment 1 obtains is carried out wear resistance and corrosion resistance test, and its main testing instrument is as follows:

[0029] TT260 Layer Thickness Gauge: Beijing Times Peak Technology Co., Ltd. Can be used to measure the thickness of the film layer;

[...

Embodiment 2

[0038] Embodiment 2: Carry out the micro-arc oxidation treatment of the present invention to copper according to the conditions of embodiment 1, wherein the thickness of the aluminum film prepared by magnetron sputtering is 60 microns. Compared with the corresponding untreated copper, the wear resistance is increased by about 17 times, and the corrosion resistance current is reduced by about 3 orders of magnitude.

Embodiment 3

[0039] Embodiment 3: Zinc is subjected to the micro-arc oxidation treatment of the present invention according to the conditions of Embodiment 1, wherein the thickness of the aluminum film prepared by magnetron sputtering is 45 microns. Compared with the corresponding untreated zinc, the wear resistance is increased by about 12 times, and the corrosion resistance current is reduced by about 2 orders of magnitude.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com