Environment-friendly multi-time hydrophilic finishing agent for polyolefin non-woven fabric

An environmentally friendly, hydrophilic finishing agent technology, applied in textiles and papermaking, fiber types, fiber treatment, etc., can solve problems such as difficult biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1.1. Formula:

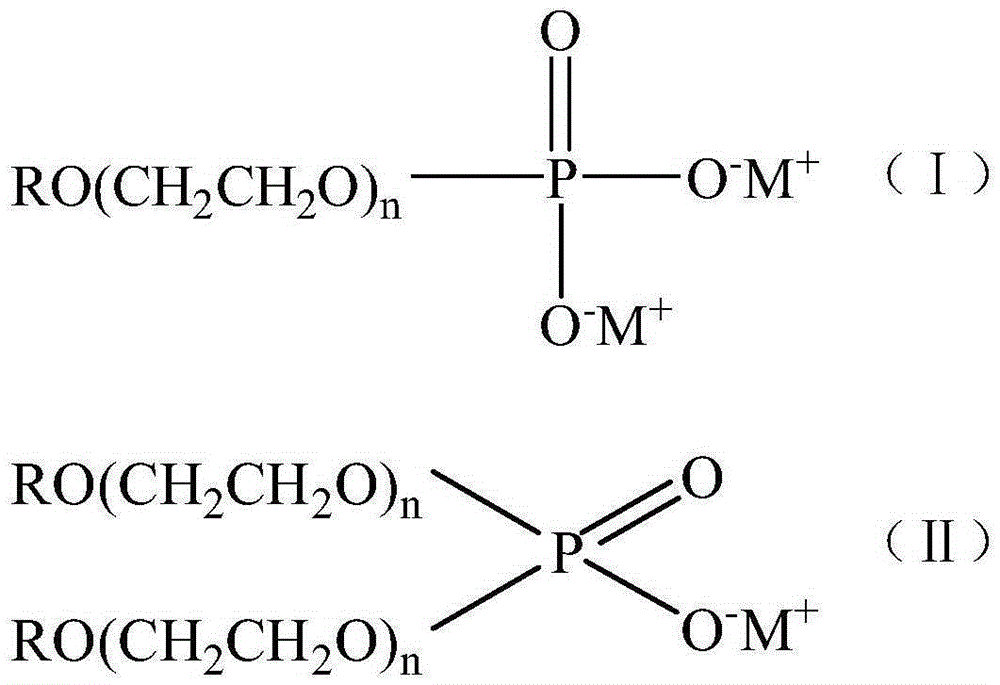

[0045] Component (A): Isooctyl polyoxyethylene ether (3) phosphate ammonium salt (molar ratio of monoester and diester is about 1:1): 28%,

[0046] Component (B): diglyceryl laurate diester polyoxyethylene ether (20) ester: 16%,

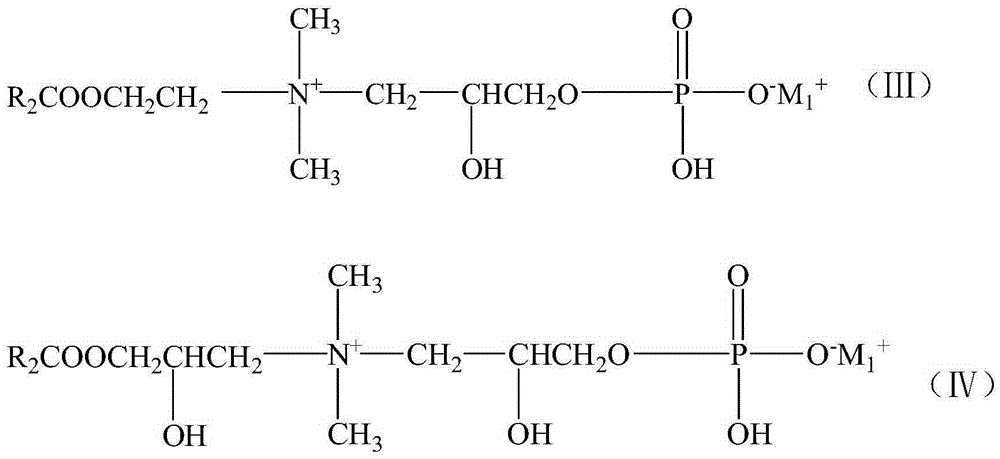

[0047] Component (C): 3-{N-(2-lauroyloxyethyl)-N,N-dimethylammonium}-2-hydroxypropyl acidic phosphate sodium betaine: 12%,

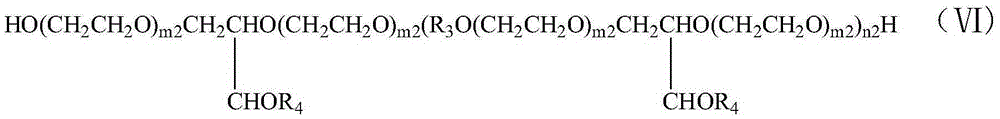

[0048] Component (D): polycondensate of dimer acid / mono-oleic acid polyoxyethylene ether (40) (m 2 ≈20, degree of condensation n 2 ≈5): 24%,

[0049] Additional water: 20%;

[0050] 1.2, the preparation of component (D):

[0051] a. Preparation of oleic acid monoglyceride polyoxyethylene ether by ethylene oxide addition polymerization method: add 354 kg of oleic acid monoglyceride and 0.7 kg of potassium hydroxide into the reaction kettle, stir and heat to 130-150 °C, and then vacuumize To -0.08~-0.09MPa, dehydrate for 20 minutes, close the vacuum valve, fill with nitrogen to 0.06MPa, then evacuate ...

Embodiment 2

[0056] 2.1. Formula:

[0057] Component (A): Isomerized tridecyl polyoxyethylene ether (5) phosphate ammonium salt (mono-diester molar ratio about 1:1): 28%,

[0058] Component (B): Dipolyglycerol diester polyoxyethylene ether (30) ester: 16%,

[0059] Component (C): 3-{N-(3-oleoyloxy-2-hydroxypropyl)-N,N-dimethylammonium}-2-hydroxypropyl acidic phosphate sodium betaine: 12% ,

[0060] Component (D): dimer acid / polyoxyethylene ether (25) condensation polymer (m 1 ≈25, degree of condensation n 1 ≈9): 24%,

[0061] Additional water: 20%;

[0062] 2.2, the preparation of component (D):

[0063] a. Preparation of polyoxyethylene ether dimer ester by addition polymerization of ethylene oxide: Add 565kg of dimer acid and 2.0kg of potassium hydroxide to the reaction kettle, stir and heat to 150-170°C, then vacuumize to -0.08 ~-0.09MPa, dehydrate for 20 minutes, close the vacuum valve, fill nitrogen to 0.06MPa, then vacuumize to -0.08MPa, fill nitrogen, repeat 3 times in total,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com