Environmentally friendly polyolefin nonwoven fabric multiple times hydrophilic finishing agent

An environmentally friendly, hydrophilic finishing agent technology, applied in textiles and papermaking, fiber processing, etc., can solve problems such as difficult biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1.1. Formula:

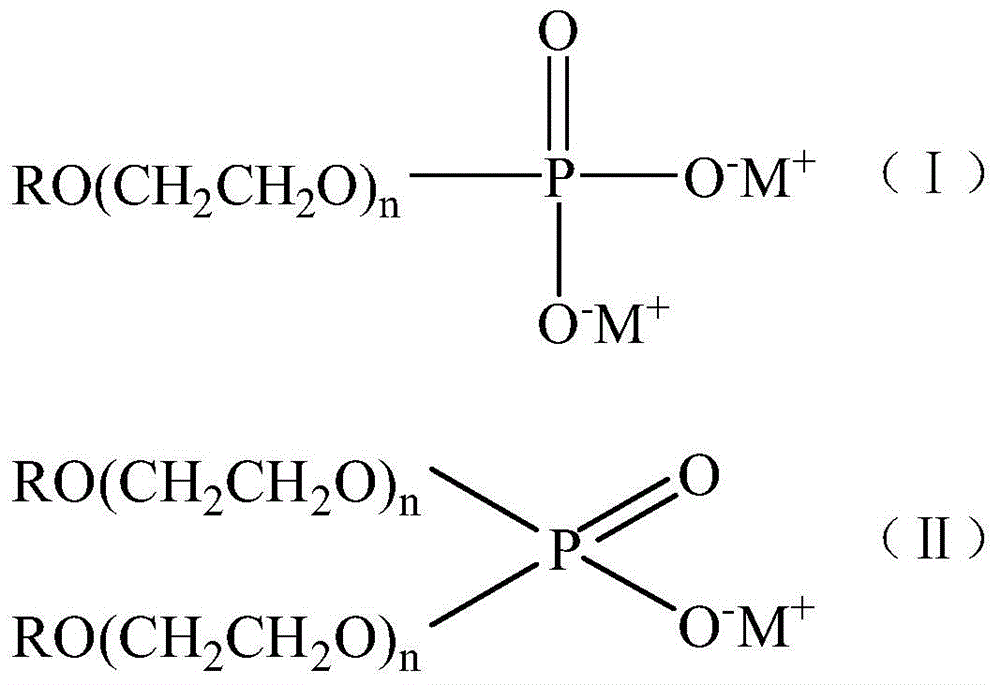

[0045] Component (A): Isooctyl polyoxyethylene ether (3) phosphate ammonium salt (molar ratio of monoester and diester is about 1:1): 28%,

[0046] Component (B): diglyceryl laurate diester polyoxyethylene ether (20) ester: 16%,

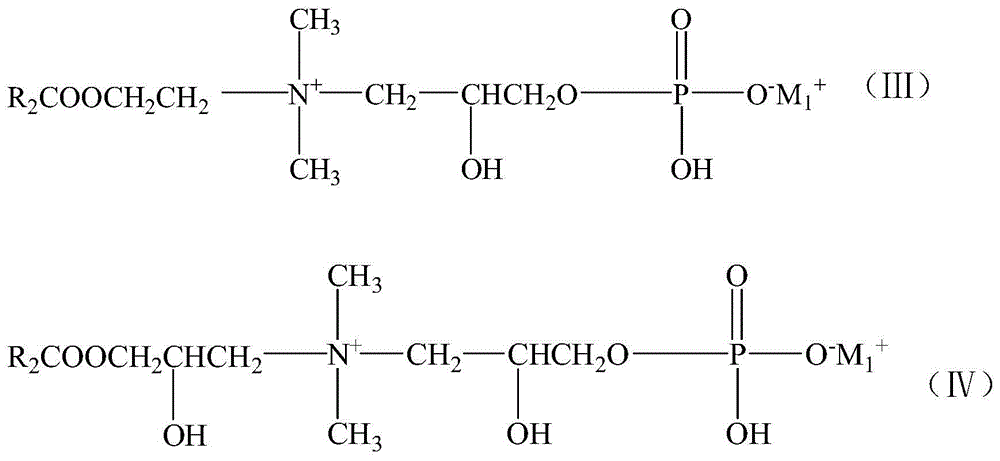

[0047] Component (C): 3-{N-(2-lauroyloxyethyl)-N,N-dimethylammonium}-2-hydroxypropyl acidic phosphate sodium betaine: 12%,

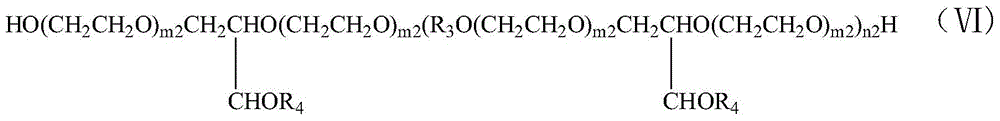

[0048] Component (D): polycondensate of dimer acid / mono-oleic acid polyoxyethylene ether (40) (m 2 ≈20, degree of condensation n 2 ≈5): 24%,

[0049] Additional water: 20%;

[0050] 1.2, the preparation of component (D):

[0051] a. Preparation of oleic acid monoglyceride polyoxyethylene ether by ethylene oxide addition polymerization method: add 354 kg of oleic acid monoglyceride and 0.7 kg of potassium hydroxide into the reaction kettle, stir and heat to 130-150 °C, and then vacuumize To -0.08~-0.09MPa, dehydrate for 20 minutes, close the vacuum valve, fill with nitrogen to 0.06MPa, then evacuate ...

Embodiment 2

[0056] 2.1. Formula:

[0057] Component (A): Isomerized tridecyl polyoxyethylene ether (5) phosphate ammonium salt (mono-diester molar ratio about 1:1): 28%,

[0058] Component (B): Dipolyglycerol diester polyoxyethylene ether (30) ester: 16%,

[0059] Component (C): 3-{N-(3-oleoyloxy-2-hydroxypropyl)-N,N-dimethylammonium}-2-hydroxypropyl acidic phosphate sodium betaine: 12% ,

[0060] Component (D): dimer acid / polyoxyethylene ether (25) condensation polymer (m 1 ≈25, degree of condensation n 1 ≈9): 24%,

[0061] Additional water: 20%;

[0062] 2.2, the preparation of component (D):

[0063] a. Preparation of polyoxyethylene ether dimer ester by addition polymerization of ethylene oxide: Add 565kg of dimer acid and 2.0kg of potassium hydroxide to the reaction kettle, stir and heat to 150-170°C, then vacuumize to -0.08 ~-0.09MPa, dehydrate for 20 minutes, close the vacuum valve, fill nitrogen to 0.06MPa, then vacuumize to -0.08MPa, fill nitrogen, repeat 3 times in total,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com