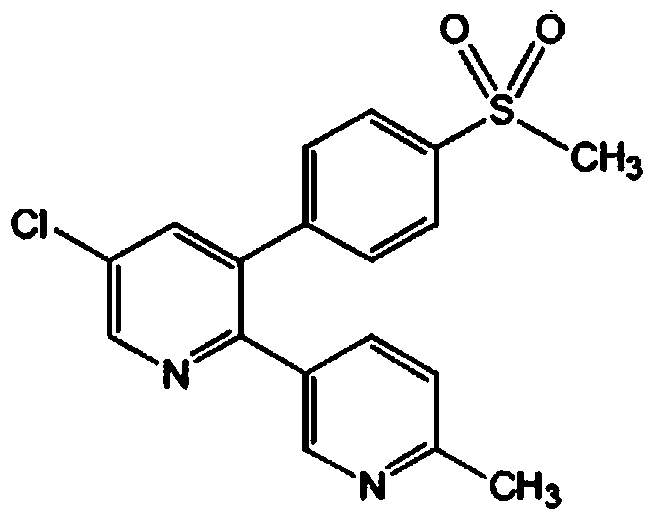

A kind of etoricoxib oral microemulsion preparation and preparation method thereof

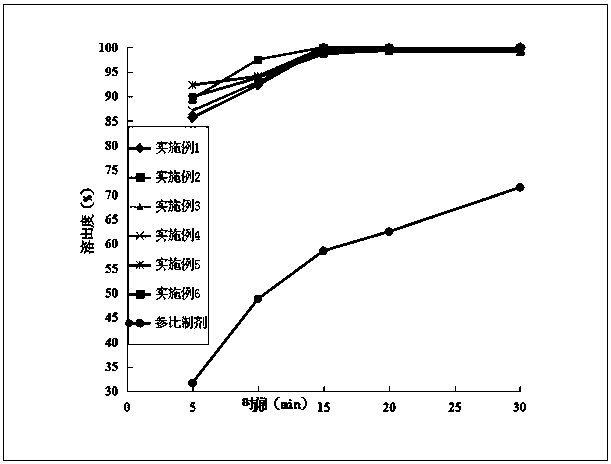

A technology of etoricoxib and milk preparations, applied in anti-inflammatory agents, pharmaceutical formulations, emulsion delivery, etc., can solve the problems of poor solubility and low bioavailability, and achieve the goal of masking bitterness, increasing solubility, and improving bioavailability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prescription composition:

[0035] Name of raw material percentage 10 prescription bottles etoricoxib 1% 1g Soybean oil 3% 3g polyoxyethylene castor oil 5% 5g Propylene Glycol 4% 4g polyethylene glycol 400 3% 3g sodium benzoate 0.1% 0.1g Deionized water 83.9% 83.9g

[0036] Preparation Process:

[0037] (1) Take 1g of etoricoxib, add 3g of soybean oil to dissolve at room temperature;

[0038] (2) Add 5 g of polyoxyethylene castor oil, 4 g of propylene glycol and 3 g of polyethylene glycol 400 into (1), stir magnetically for 5 min, add about 28 g of deionized water, and continue stirring for 10 min to form a coarse milk;

[0039] (3) Transfer the mixture in (2) to a high-pressure homogenizer, add 0.1g of sodium benzoate, add the remaining 55.9g of deionized water, turn on the high-pressure homogenizer, perform high-pressure homogenization for 5 minutes, and repeat 3 times to prepare micro dairy products...

Embodiment 2

[0041] Prescription composition:

[0042] Name of raw material percentage 10 prescription bottles etoricoxib 1% 1g Medium-chain triglycerides 5% 5g ethyl oleate 2% 2g

[0043] polyoxyethylene castor oil 7% 7g glycerin 10% 10g aspartame 0.1% 0.1g lemon zest 0.25% 0.25g sodium benzoate 0.2 0.2g distilled water 74.45% 74.45g

[0044] Preparation Process:

[0045] (1) Take 1g etoricoxib, add 5g medium carbon chain triglycerides and 2g ethyl oleate to dissolve at room temperature;

[0046] (2) Add 7g of polyoxyethylene castor oil and 10g of glycerin to (1), sonicate for 10min, add 25g of distilled water and continue sonicating for 10min to form a coarse milk;

[0047] (3) Transfer the mixture in (2) to a high-pressure homogenizer, add 0.1g of aspartame, 0.25g of lemon essence, add the remaining 49.45g of distilled water, turn on the high-pressure homogenizer, homogenize under high pressure f...

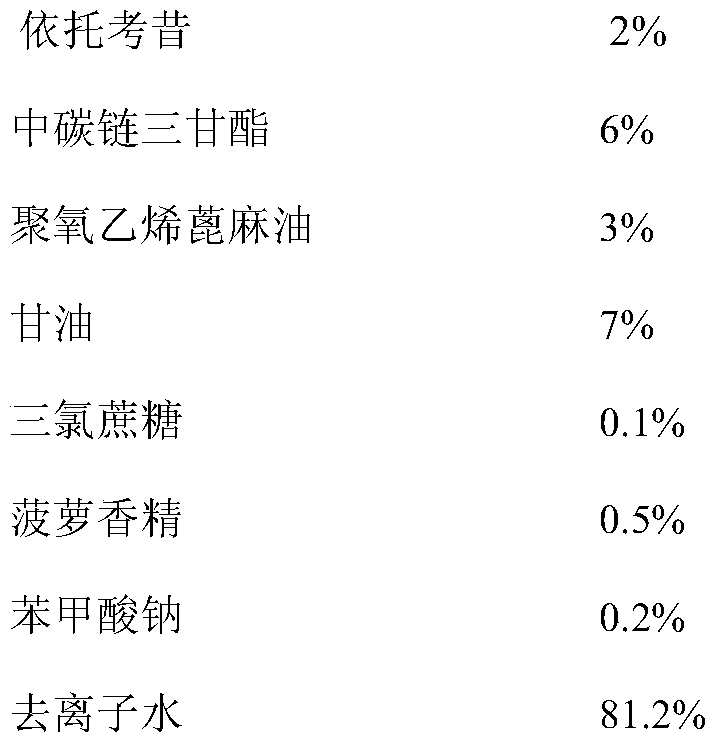

Embodiment 3

[0049] Prescription composition:

[0050] Name of raw material percentage 100 prescription bottles etoricoxib 2% 2g castor oil 10% 10g Polyoxyethylene Hydrogenated Castor Oil 7% 7g Propylene Glycol 10% 10g aspartame 0.2% 0.2g pineapple flavor 0.25% 0.25g sodium benzoate 0.3% 0.3g Deionized water 70.25% 70.25g

[0051] Preparation Process:

[0052] (1) Take 2g of etoricoxib, add it to 10g of castor oil and heat to 40°C to dissolve;

[0053] (2) Add 7 g of polyoxyethylene castor oil and 10 g of propylene glycol into (1), stir mechanically for 10 min, add 23 g of deionized water, and continue stirring for 10 min to form a coarse milk.

[0054](3) Transfer the mixture in (2) to a high-pressure homogenizer, add 0.2g aspartame, 0.25g pineapple essence and 0.3g sodium benzoate, add the remaining 47.25g deionized water, turn on the high-pressure homogenizer, and Homogenize for 5 minutes and repeat 3 times to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com