Brewing production method of medlar and apple mix fermented fruit wine

A production method and apple technology, applied in the field of fruit wine brewing, can solve the problems of insufficient sugar and acid of wolfberry, loss of nutritional components of wolfberry, large production cost, etc., and achieve the effects of maintaining flavor quality, reducing production cost and retaining nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] After 1000kg of dried wolfberry is cleaned, it is pumped into a 5kL fermentation tank with a pulp pump, and 2500L of drinking water is pumped into it for rehydration at the same time;

[0026] Add food grade potassium metabisulfite (60mg / L) and pectinase (20mg / L) while pumping, and fill the tank mouth with CO 2 prevent oxidation;

[0027] After soaking at low temperature (4-9°C) for 3 days, take the clear juice of wolfberry, squeeze the skin dregs with an air bag press, and combine the artesian juice and lightly pressed juice;

[0028] Pump 5000L of 1:4 diluted concentrated apple juice, and add tartaric acid to adjust the acid to pH less than 3.9;

[0029] After returning to 15°C, inoculate activated active dry yeast (0.2g / L) to start fermentation;

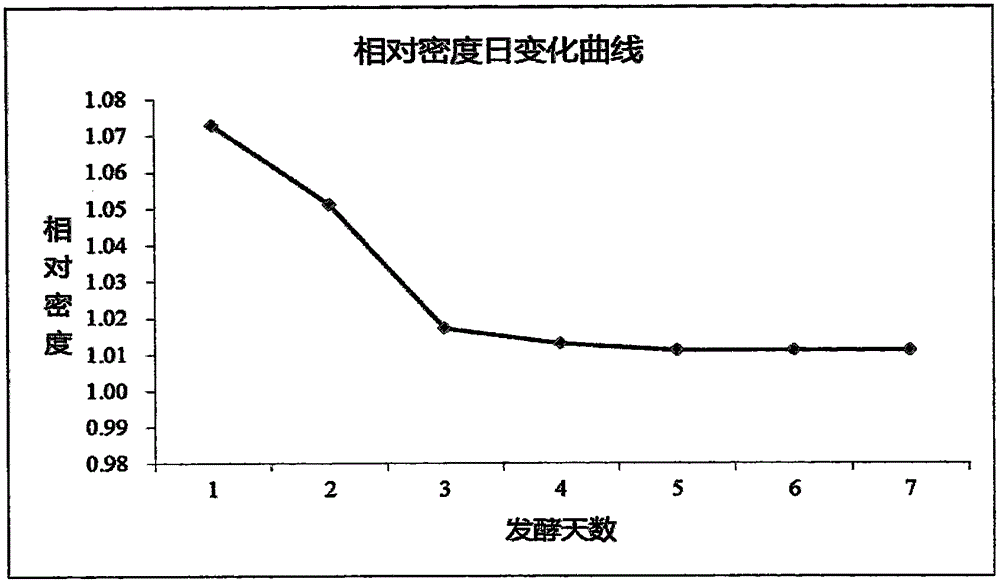

[0030] The fermentation temperature is controlled at 15-20°C, and the temperature and specific gravity of the samples in each tank are regularly measured every day;

[0031] After the residual sugar drops below 18g / L, co...

example 2

[0037] 2000kg of high-quality dried goji berries that have been color-selected are washed and pumped into a 5kL fermentation tank with a pulp pump, during which time 2000L of drinking water is pumped in for rehydration;

[0038] Add potassium metabisulfite (45mg / L) and pectinase (20mg / L) while pumping, and fill the tank mouth with CO 2 prevent oxidation;

[0039] After soaking at low temperature (4-9°C) for 5 days, take the clear juice of wolfberry, squeeze the dregs with an air bag press, and combine the artesian juice and lightly pressed juice;

[0040] Pump 4000L of 1:4 diluted concentrated apple juice, and add tartaric acid to adjust the pH to 3.8;

[0041] After returning to 15°C, inoculate activated active dry yeast (0.2g / L) to start fermentation;

[0042] The fermentation temperature is controlled at 15-20°C, and the temperature and specific gravity of the samples in each tank are regularly measured every day;

[0043] After the residual sugar drops below 4g / L, control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com