Biofuel cell capable of directly oxidizing glucose and preparation method of biofuel cell

A biofuel cell, glucose oxidation technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of expensive electron transfer intermediates, short running time, low open circuit voltage, etc. The preparation method is simple and the effect of improving the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

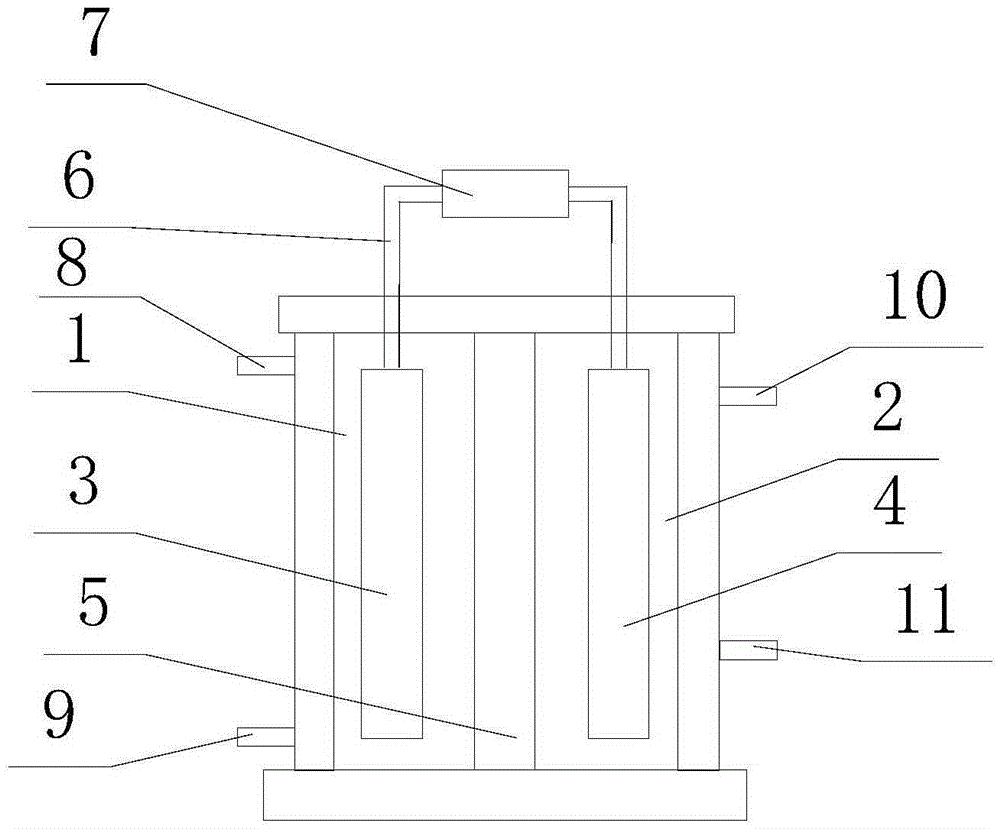

[0056] Example 1: Preparation of anode and cathode

[0057] Select the porous metal nickel mesh disk (diameter is 5cm) and clean the porous metal nickel mesh disk with acetone for 5 minutes, then use 6mol / L hydrochloric acid etching treatment for 15 minutes, then use ultrapure water to carry out ultrasonic cleaning, and finally Blow dry with a stream of nitrogen gas until ready to use.

[0058] The porous metal nickel mesh after the above treatment was put into 2 mmol / L silver nitrate solution and soaked for 30 minutes to prepare a nickel mesh electrode loaded with silver nanoparticles. Before assembling the biofuel cell, the nickel mesh electrode loaded with nano-silver particles was cleaned with ultrapure water, and then stored in 2 mol / L potassium hydroxide solution for later use.

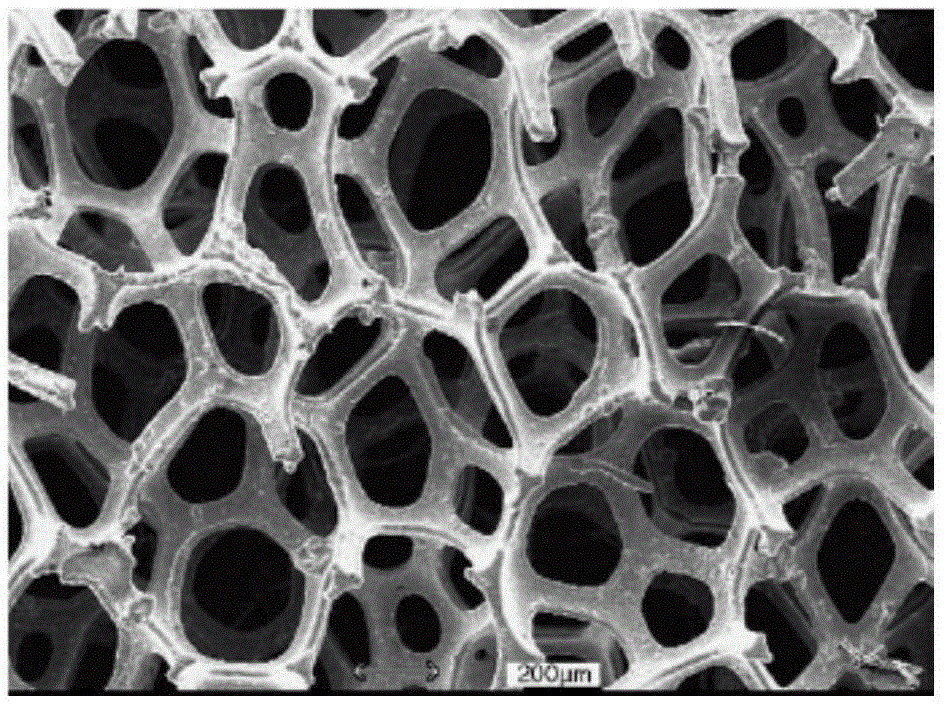

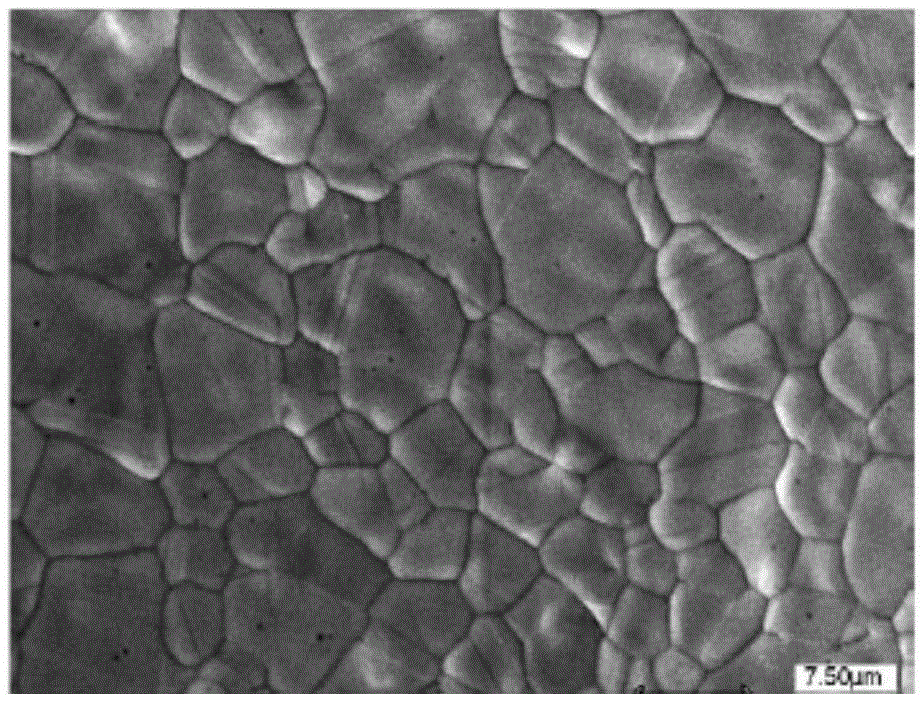

[0059] Among them, the scanning electron microscope photos of the porous metal nickel mesh are as follows: Figure 2A and Figure 2B As shown, the scanning electron micrograph of the nickel m...

example 2

[0061] PEEK anion exchange membrane (Fumasep TM FAB, with a thickness of 100um) acts as a diaphragm between the anode chamber and the cathode chamber. The anolyte is a KOH buffer solution saturated with nitrogen gas with a concentration of 0.5mol / L, and the concentration of glucose is 0.5mol / L; the catholyte is a KOH buffer solution of 0.5mol / L, which contains saturated oxygen and the flow rate of oxygen It is 100sscm.

[0062] The nickel mesh electrode loaded with nano-silver particles prepared in Example 1 is used as an anode and a cathode and packed into the anode chamber and the cathode chamber respectively and connected to the anode and the cathode with an external circuit, and the direct oxidation of glucose is obtained after adding the above-mentioned anolyte and catholyte biofuel cell.

[0063] When testing the output power curve of the direct oxidation glucose biofuel cell in this example, let the battery run for a period of time to obtain a stable open circuit volt...

example 3

[0066] The nickel mesh electrode loaded with silver nanoparticles prepared in Example 1 was used as the anode and cathode and a biofuel cell was assembled according to Example 2, wherein the concentration of glucose in the anolyte was 0.1 mol / L.

[0067] The voltage-current curve and power density-current curve of the direct oxidation glucose biofuel cell in this example are shown in Figure 4 , open circuit voltage and battery internal resistance curves see Figure 5 . In this example, the concentration of glucose is 0.1 mol / L, and the results obtained in the polarization curve, power density curve and open circuit voltage are lower than those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com