Preparation method of cheddar cheese rich in gamma-aminobutyric acid

A technology of cheddar cheese and aminobutyric acid, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of gamma-aminobutyric acid side effects, high cost, and low gamma-aminobutyric acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

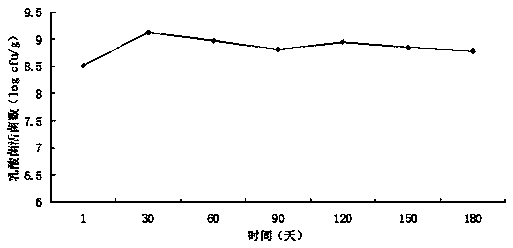

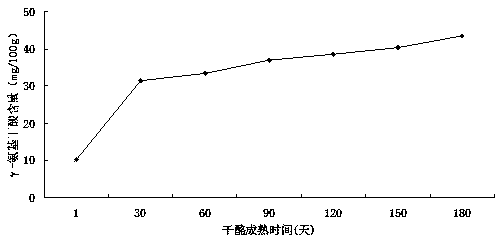

[0022] The raw milk is standardized, sterilized, inoculated with γ-aminobutyric acid-producing strains and traditional starter, added calcium chloride, added rennet, curdled milk, cut curd, stacked, salted, and matured to make a Cheddar cheese rich in gamma-aminobutyric acid. The number of viable lactic acid bacteria in cheddar cheese was 8.35×10 8 cfu / g, and the content of γ-aminobutyric acid is 43.48mg / 100g.

[0023] Its preparation method is as follows:

[0024] (1) Preparation of Streptococcus thermophilus starter: After expanding the Streptococcus thermophilus strains stored at -80°C through the improved tomato juice medium for three times, the bacteria were collected by centrifugation. The components of the improved tomato juice medium were tomato juice 50mL, yeast Extract 5g, beef extract 10g, lactose 20g, glucose 2g, dipotassium hydrogen phosphate 2g, Tween-801g, sodium acetate 5g, distilled water 1000mL, pH6.8;

[0025] (2) Raw material standardization and steriliz...

Embodiment 2

[0036] A preparation method of cheddar cheese rich in gamma-aminobutyric acid:

[0037] (1), (2), (4)-(10) are the same as Steps (1), (2), (4)-(10) of Example 1;

[0038] (3) Add starter: cool to 31°C, add 200DCU of commercial direct-injection starter, 1×10 starter starter of γ-aminobutyric acid producing strain 8 cfu / mL, probiotic starter, let it stand for 30 minutes until the acidity is 0.20%.

[0039] (11) Quality standard: the number of live lactic acid bacteria in cheddar cheese is 8.65×10 8 cfu / g, and the content of γ-aminobutyric acid is 44.40mg / 100g, the number of viable probiotic bacteria is 1.25×10 7 cfu / g.

[0040] A cheddar cheese rich in gamma-aminobutyric acid prepared by the method has the physiological efficacy of the gamma-aminobutyric acid and increases the physiological efficacy of probiotics.

Embodiment 3

[0042] A preparation method of cheddar cheese rich in gamma-aminobutyric acid:

[0043] (1), (3), (4)-(10) are the same as Steps (1), (3), (4)-(11) of Example 1;

[0044] (2) Raw material standardization and sterilization: After 1000kg of fresh milk is filtered to remove impurities, 500g of sodium glutamate is added, and prebiotic factors (polysaccharides, dietary fiber, etc.) are added to sterilize at 63°C for 30 minutes;

[0045] The gamma-aminobutyric acid-rich cheddar cheese prepared by the method has the physiological efficacy of the gamma-aminobutyric acid and increases the physiological efficacy of prebiotic factors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com