Preparation method for broad-spectrum-response titanium dioxide hollow micro-nanospheres

A technology of titanium dioxide and micro-nano spheres, which is applied in the field of photocatalytic materials, can solve problems such as reducing the stability of composite material systems, potential risks to human health and safety, and negative impacts on the ecological environment, so as to avoid harm to the human body and stability performance, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

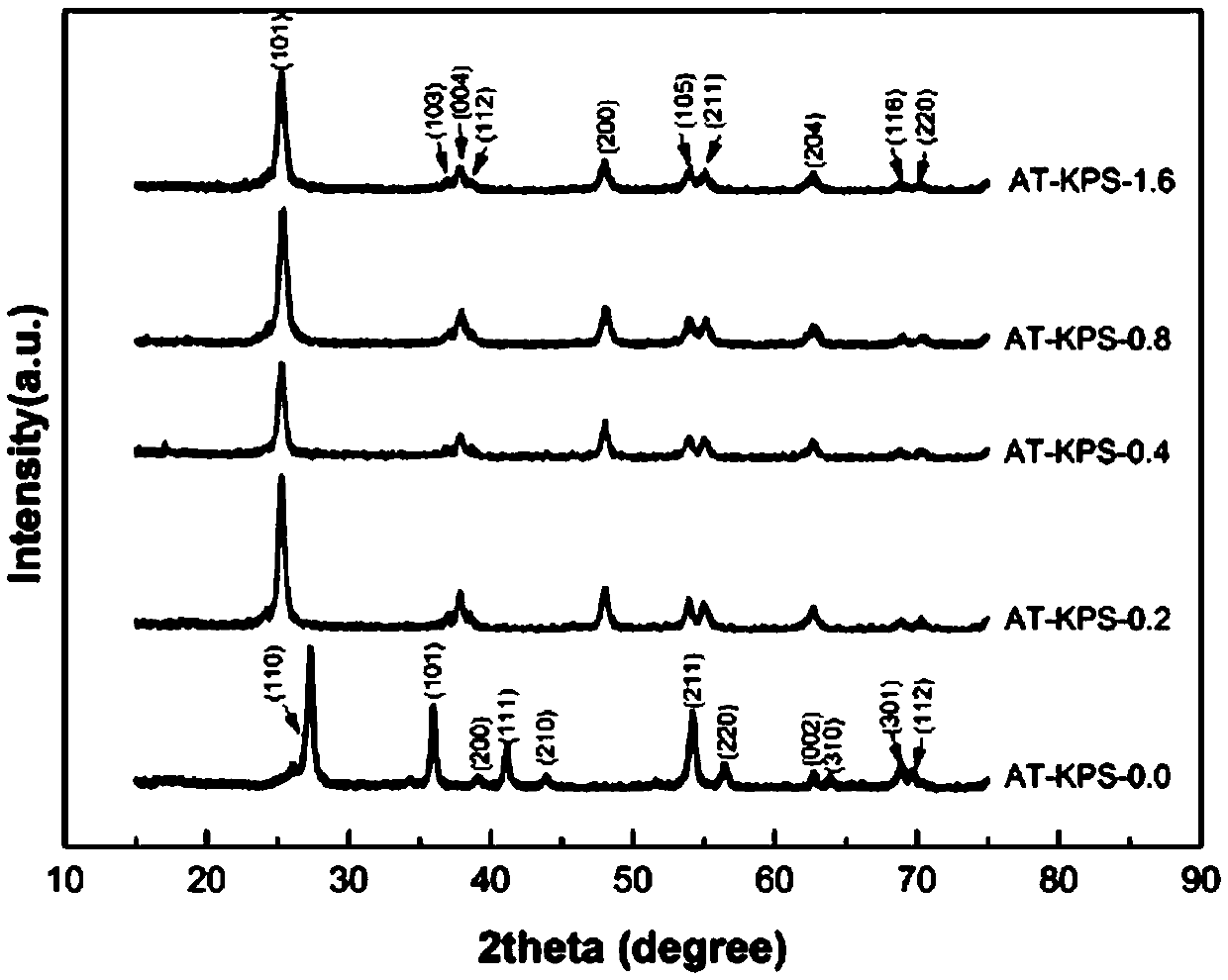

[0024] In order to achieve the above purpose, the technical scheme adopted in the preparation method of a broad-spectrum response titanium dioxide hollow micro-nanosphere of the present invention is: introducing a template agent and a chelating complexing agent into the hydrothermal reaction system to induce the directional deposition of titanium ions And control the growth mode of the titanium dioxide crystal growth unit, and obtain the titanium dioxide micro-nanosphere with hollow structure and broad-spectrum response characteristics after removing the inner core by calcination. The specific steps are:

[0025] 1) Using self-made monodisperse polystyrene spheres with negative charges on the surface as a template, the polystyrene sphere template and TiCl 3 The aqueous solution is mixed, and a certain amount of soluble persulfate is added as a chelating complexing agent, and then transferred into a hydrothermal reaction kettle. The soluble persulfate is potassium persulfate, s...

Embodiment 1

[0033] Take 0.2 g of polystyrene balls with a diameter of 700 nm and 0.15 mol / L of TiCl 3 90 mL of the aqueous solution was mixed under the condition of 800 r / min magnetic stirring, and then 1 g of potassium persulfate was added. Transfer the above mixed solution into a 100mL hydrothermal reaction kettle lined with tetrafluoroethylene, seal and mark. The above reaction kettle was put into a drying oven preheated to 200°C in advance, and kept at 200°C for 3 hours to carry out hydrothermal reaction. After naturally cooling to room temperature, the solid product in the reactor was washed several times with deionized water, and then dried at 60°C. Put the dried sample into the muffle furnace, raise the temperature up to 500°C at a rate of 5°C / min and keep it for 4 hours, then raise it to 600°C at a rate of 2°C / min and keep it for 2 hours, and finally obtain a titanium dioxide hollow microstructure. ball structure.

Embodiment 2

[0035] The only difference from Example 1 is that the consumption of potassium persulfate is 1.2g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com