Solar battery based on inorganic bulk heterojunction and preparation method thereof

A technology of solar cells and bulk heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable energy transfer of absorbing materials, unsatisfactory interface contact, unfavorable energy transfer, etc., and achieve great application value and equipment requirements. Low effect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

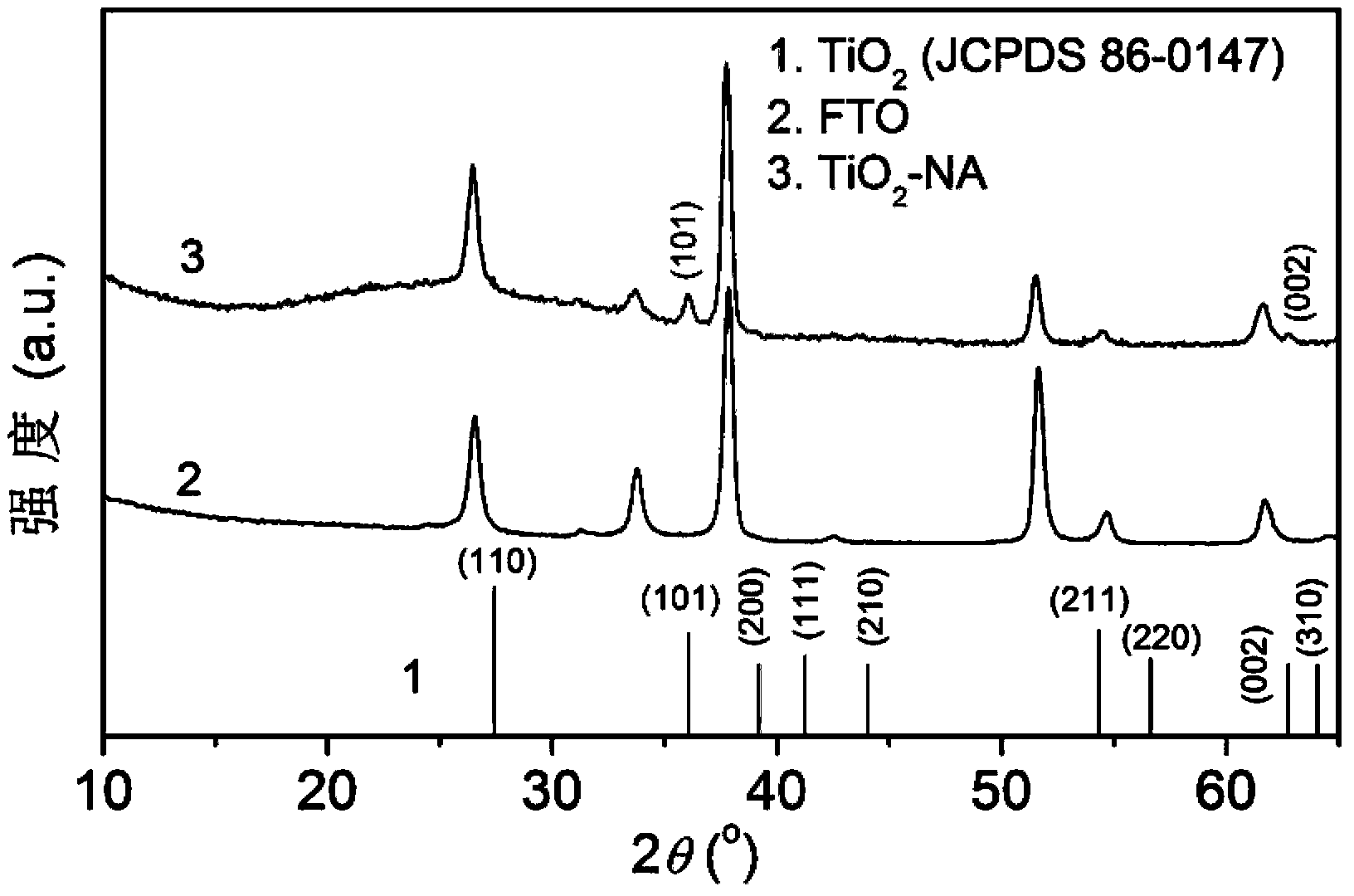

[0045] Example 1: TiO 2 Fabrication of Nanorod Arrays.

[0046] (1-1) Preparation of nanorod arrays:

[0047] First, the FTO on the FTO conductive glass (FTO thickness 400 nm, 14 Ω / □) was etched to 16 × 4 mm with a mixture of concentrated HCl-water and Zn powder with a volume ratio of 1:1 2 Thin strips; then ultrasonically cleaned with acetone, isopropanol, and ultrapure water, and dried to obtain the treated FTO conductive glass.

[0048] Dissolve 30 mL of concentrated hydrochloric acid in 30 mL of deionized water, stir evenly, then add 1 mL of butyl titanate and stir for 15 minutes to obtain a reaction solution; place the treated FTO conductive glass face down in a 100 mL high-pressure In the autoclave, add the pre-prepared reaction solution into the autoclave, seal it and react in an oven at 180 °C for 2.5 hours; after the autoclave is cooled to room temperature, take out the sample and rinse it with deionized water several times to obtain TiO 2 The primary product of na...

Embodiment 2

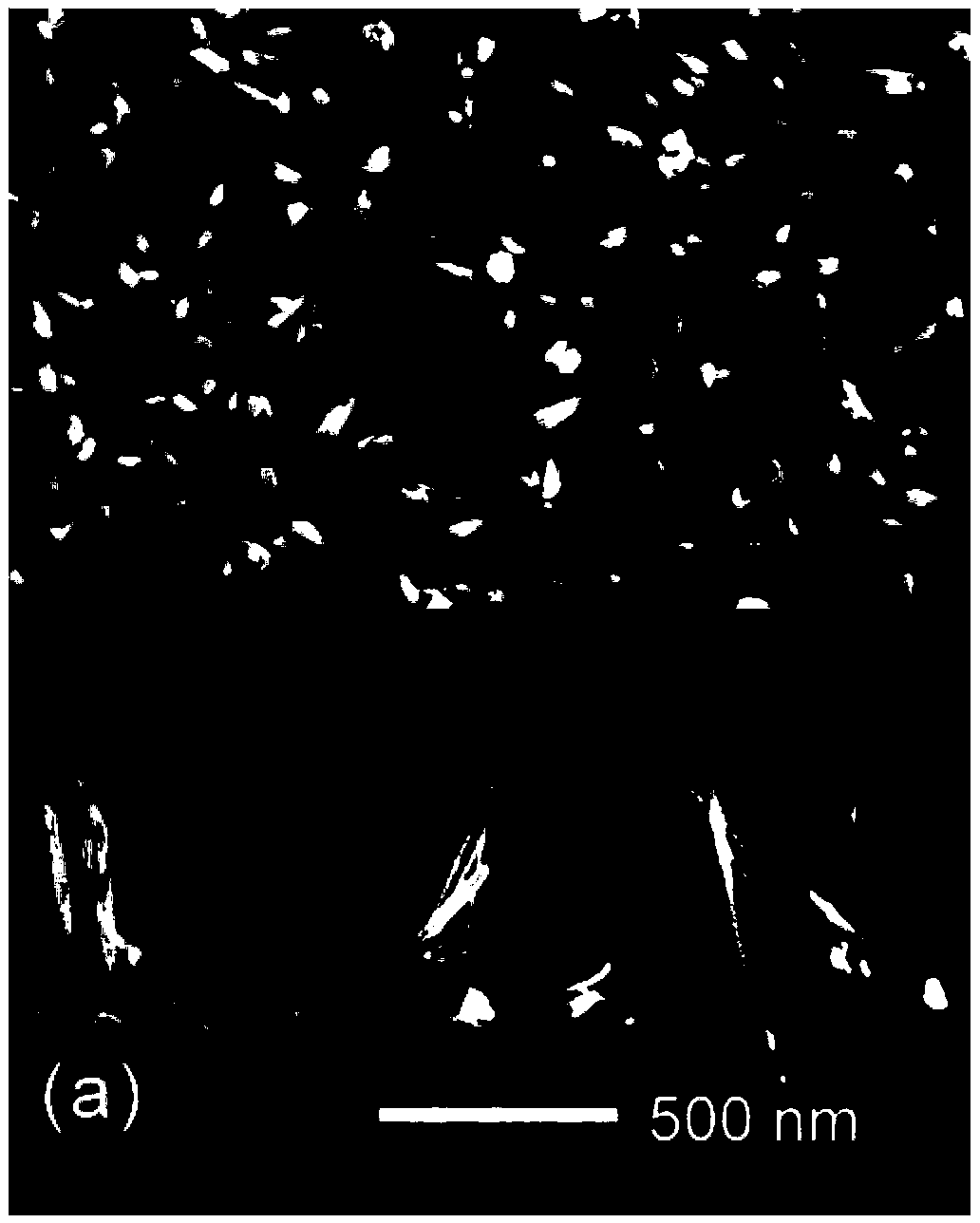

[0051] Example 2: Sb 2 S 3 / TiO 2 - Preparation of NA composite membranes.

[0052] (2-1)TiO 2 Preparation of nanorod array: same as Example 1.

[0053] (2-2) Sb 2 S 3 / TiO 2 Preparation of -NA composite membrane:

[0054] 360 mL of 0.28 M Na 2 S 2 o 3 The solution was cooled in an ice-water bath for 20 minutes to lower the temperature to about 5 °C, and then the TiO 2 The nanorod arrays were placed face down on the Na 2 S 2 o 3 solution; to Na at a rate of 2 mL / min 2 S 2 o 3 Add 40 mL of 0.29 M SbCl dropwise to the solution 3 acetone solution, keep cooling with ice bath during the dropwise addition of Na 2 S 2 o 3 solution; after the dropwise addition, the reaction was continued for 6 hours under ice-water bath cooling conditions, and the Sb 2 S 3 chemical bath deposition. After deposition, remove the TiO 2 The nanorod array sample was washed several times with deionized water, and then dried with nitrogen to obtain an orange-red primary product; the p...

Embodiment 3

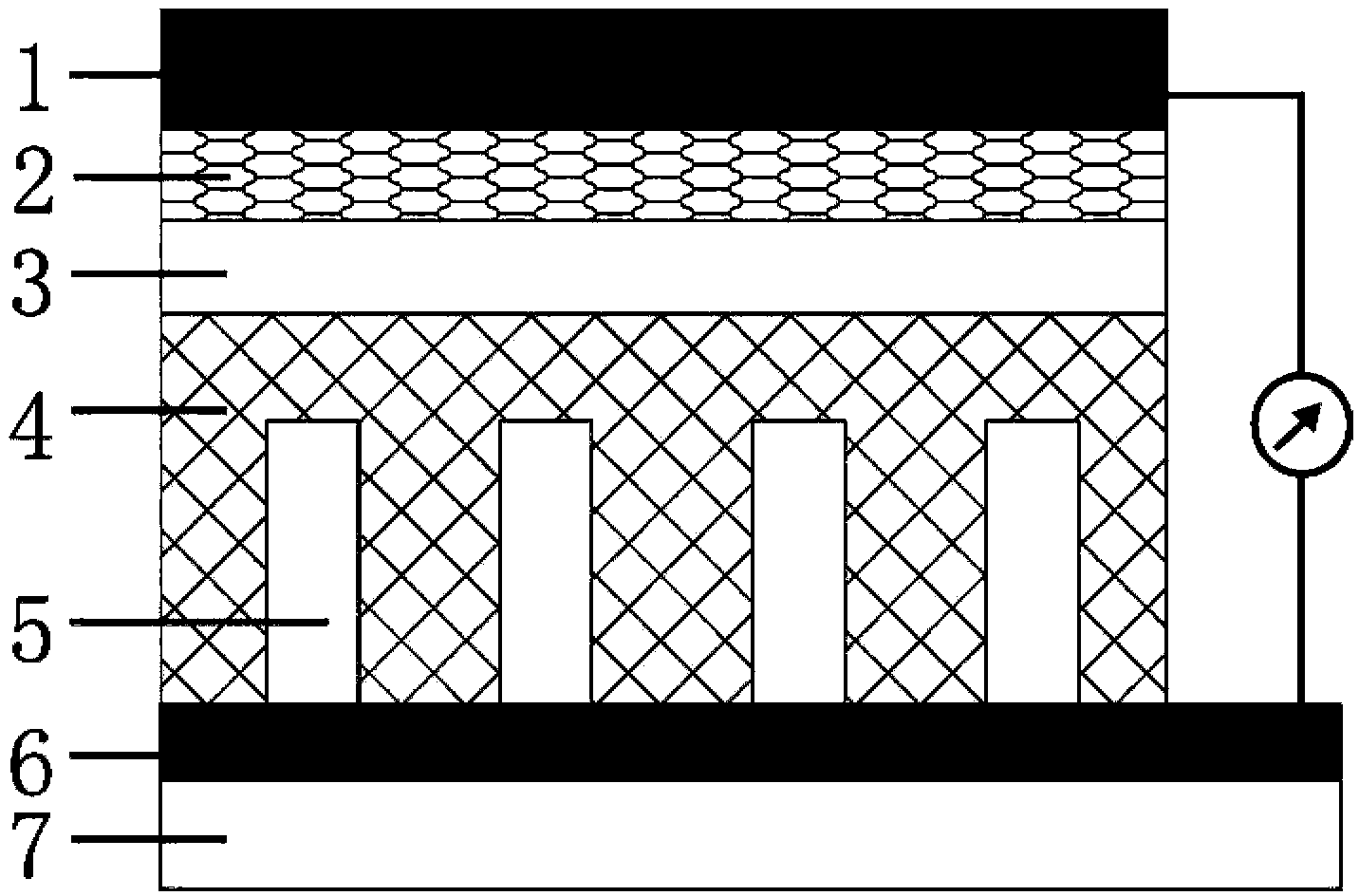

[0058] Example 3: Sb 2 S 3 / TiO 2 - Fabrication of NA bulk heterojunction solar cells.

[0059] (3-1)TiO 2 Preparation of nanorod array: same as Example 1.

[0060] (3-2) Sb 2 S 3 / TiO 2 -Preparation of NA composite film: same as Example 2.

[0061] (3-3)Sb 2 S 3 / TiO 2 - Fabrication of NA bulk heterojunction solar cells.

[0062] Using freshly distilled chlorobenzene as a solvent, prepare a MEH-PPV solution with a concentration of 5 mg / mL and stir it at room temperature for 24 hours. Disperse 150 μL of MEH-PPV solution evenly in the Sb 2 S 3 / TiO 2 -NA composite film, spin coating (1000 rpm, 60 sec) to deposit MEH-PPV onto Sb 2 S 3 / TiO 2 -NA composite film; after vacuum drying at 40 ℃ for 6 hours, heat treatment at 150 ℃ for 10 minutes under nitrogen protection, the Sb 2 S 3 / TiO 2 A MEH-PPV film with a thickness of about 40 nm was formed on the NA composite film as an electron blocking layer. Spin-coat a mixture of PEDOT:PSS and isopropanol (volume rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com