Biomass charcoal high efficiency controlled release fertilizer

A technology of biomass charcoal and slow-release fertilizer, applied in the agricultural field, can solve the problems of reduced slow-release effect and absorption effect, high product cost, insufficient thickness, etc., and achieve the effects of reasonable composition, compressed product cost, and suitable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

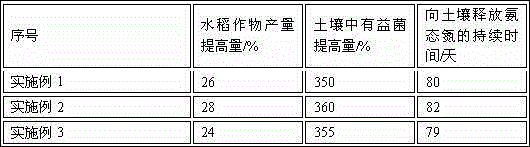

Examples

Embodiment 1

[0016] A biochar high-efficiency slow-release fertilizer, which consists of the following raw materials in parts by weight: 70 parts of biochar, 10 parts of microbial bacteria, 25 parts of corn stalk pellets, 5 parts of urea, 6 parts of potassium sulfate, and 6 parts of potassium manganate Parts, 7 parts of binder and 10 parts of attapulgite.

[0017] In this embodiment, the chemical composition (mass percentage) of the biochar is: 45% crude fiber, 25% lignin, 15% ash, and 15% silicon dioxide.

[0018] In this embodiment, the binder is specifically an aqueous solution of polyvinyl alcohol with a concentration of 5.0%.

[0019] Preferably, the nitrogen content in the urea is 46.2%.

[0020] A preparation method of biochar high-efficiency slow-release fertilizer, comprising the following steps:

[0021] (1) Put the biomass charcoal, microbial bacteria, corn stalk pellets, urea, potassium sulfate, potassium manganate and attapulgite into the stirring pulverizer according to the...

Embodiment 2

[0025] A biochar high-efficiency slow-release fertilizer, which consists of the following raw materials in parts by weight: 80 parts of biochar, 14 parts of microbial bacteria, 15 parts of corn stalk pellets, 8 parts of urea, 6 parts of potassium sulfate, and 7 parts of potassium manganate Parts, 9 parts of binder and 10 parts of attapulgite.

[0026] In this embodiment, the chemical composition (mass percentage) of the biochar is: 45% crude fiber, 25% lignin, 15% ash, and 15% silicon dioxide.

[0027] In this embodiment, the binder is specifically an aqueous solution of polyvinyl alcohol with a concentration of 5.0%.

[0028] Preferably, the nitrogen content in the urea is 46.2%.

[0029] A preparation method of biochar high-efficiency slow-release fertilizer, comprising the following steps:

[0030] (1) Put the biomass charcoal, microbial bacteria, corn stalk pellets, urea, potassium sulfate, potassium manganate and attapulgite into the stirring pulverizer according to the...

Embodiment 3

[0034] A biochar high-efficiency slow-release fertilizer, which is composed of the following raw materials in parts by weight: 85 parts of biochar, 15 parts of microbial bacteria, 15 parts of corn stalk pellets, 5 parts of urea, 7 parts of potassium sulfate, and 6 parts of potassium manganate Parts, 12 parts of binder and 11 parts of attapulgite.

[0035] In this embodiment, the chemical composition (mass percentage) of the biochar is: 45% crude fiber, 25% lignin, 15% ash, and 15% silicon dioxide.

[0036] In this embodiment, the binder is specifically an aqueous solution of polyvinyl alcohol with a concentration of 5.0%.

[0037] Preferably, the nitrogen content in the urea is 46.2%.

[0038] A preparation method of biochar high-efficiency slow-release fertilizer, comprising the following steps:

[0039] (1) Put the biomass charcoal, microbial bacteria, corn stalk pellets, urea, potassium sulfate, potassium manganate and attapulgite into the stirring pulverizer according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com