Preparation method of high-purity n-butylphthalide

A high-purity technology of n-butylphthalide, applied in the field of medicine, can solve problems such as cost increase, environmental pollution, and harsh operating conditions, and achieve the effects of less equipment occupation, short synthesis process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

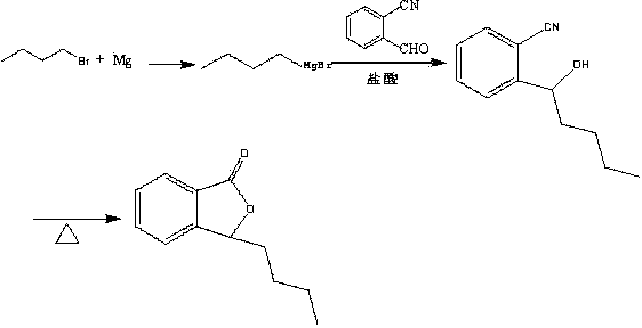

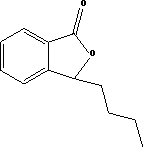

Method used

Image

Examples

Embodiment 1

[0026] Add 5.28g (0.22mol) magnesium strips into a 250ml four-necked bottle, add a grain of elemental iodine and 25ml ether, stir, add about 1g of n-butyl bromide, and slowly add the remaining n-butyl bromide dropwise after the reaction is initiated. A total of 30.14 g (0.22 mol) of butyl bromide was added, and 100 ml of isopropyl ether was added at the same time. The addition was completed dropwise in about 1 hour, and then refluxed for another 1 hour, cooled, and set aside.

[0027] 2. Crude product preparation

[0028] Add 29.20g (0.2mol) of o-cyanobenzaldehyde into a 500ml four-necked bottle, add it into 150ml of isopropyl ether, stir, add 0.5g of cuprous iodide, cool down to -25°C, and drop the temperature at -25±2°C Add the above-mentioned Grignard reagent, drop it for about 1 hour, keep stirring at -20±2°C for 2 hours, add 10% hydrochloric acid dropwise, adjust the pH to 2~3, after dropping, heat and reflux for 2 hours, separate the water layer, and organic The layer w...

Embodiment 2

[0034] 1. Preparation of Grignard reagent

[0035] Add 11.04g (0.46mol) magnesium strips into a 500ml four-necked bottle, add a grain of elemental iodine and 50ml ether, stir, add about 2g of n-butyl bromide, and slowly add the remaining n-butyl bromide dropwise after the reaction is triggered, and the normal A total of 63.02 g (0.46 mol) of butyl bromide was added, and 200 ml of isopropyl ether was added at the same time. The addition was completed dropwise in about 1 hour, and then refluxed for 1 hour, cooled, and set aside.

[0036] 2. Crude product preparation

[0037] Add 58.40g (0.4mol) of o-cyanobenzaldehyde into a 1000ml four-necked bottle, add 300ml of isopropyl ether, stir, add 1.0g of cuprous iodide, cool down to -25°C, control the temperature at -25±2°C and drop Add the above-mentioned Grignard reagent, drop it for about 1 hour, keep stirring at -20±2°C for 2 hours, add 10% hydrochloric acid dropwise, adjust the pH to 2~3, after dropping, heat and reflux for 2 hou...

Embodiment 3

[0041] 1. Preparation of Grignard reagent

[0042] Add 10.08g (0.42mol) magnesium bars into a 500ml four-necked bottle, add a grain of elemental iodine and 50ml ether, stir, add about 2g of n-butyl bromide, and slowly add the remaining n-butyl bromide dropwise after the reaction is triggered, and the normal A total of 57.54 g (0.42 mol) of butyl bromide was added, and 200 ml of isopropyl ether was added at the same time. The addition was completed dropwise in about 1 hour, and then refluxed for 1 hour, cooled, and set aside.

[0043] 2. Crude product preparation

[0044]Add 58.40g (0.4mol) of o-cyanobenzaldehyde into a 1000ml four-necked bottle, add 300ml of isopropyl ether, stir, add 1.0g of cuprous iodide, cool down to -25°C, and drop the temperature at -25±2°C Add the above-mentioned Grignard reagent, drop it for about 1 hour, keep stirring at -20±2°C for 2 hours, add 10% hydrochloric acid dropwise, adjust the pH to 2~3, after dropping, heat and reflux for 2 hours, separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com