Single liquid type metal antirust paint and preparation method thereof

A metal anti-rust, single-liquid technology, used in anti-corrosion coatings, coatings, etc., can solve the problems of low gloss, poor resistance to bending, etc., to improve corrosion resistance and bending resistance, good corrosion resistance, good The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

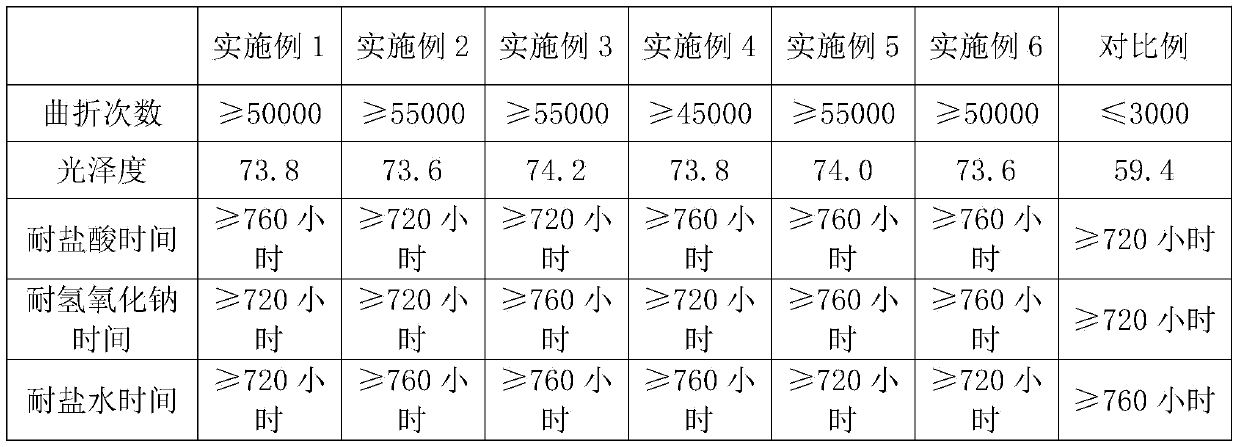

Examples

Embodiment 1

[0025] Single-component metal antirust paint, its composition in parts by weight includes: 39 parts of silicone modified styrene-acrylic emulsion, 18 parts of wollastonite powder, 4 parts of nano barium sulfate, 3.5 parts of ultrafine active magnesium hydroxide, 5 parts of propylene glycol, ethyl alcohol 4 parts of glycol ether, 3.5 parts of polymethacrylate, 1.5 parts of wax powder, 66 parts of deionized water, 11 parts of PFA, 6.5 parts of copper sulfate.

[0026] Its preparation method comprises the following steps:

[0027] (1) Add the rare earth coupling agent into propanol, disperse evenly to prepare a coupling agent solution with a mass concentration of 1%, add copper sulfate to the coupling agent solution, heat to 90° C. and stir in a constant temperature water bath for 40 minutes. The stirring speed is 5000rpm, after stopping the stirring, use a vacuum pump to filter, wash the obtained filter cake repeatedly with distilled water, place it in an oven and dry it at 90°C...

Embodiment 2

[0030] One-component metal antirust paint, its composition by weight includes: 35 parts of silicone modified styrene-acrylic emulsion, 20 parts of kaolin, 4.5 parts of nano barium sulfate, 4 parts of superfine active magnesium hydroxide, 7 parts of propylene glycol, ethylene glycol 2.4 parts of ether, 5 parts of polyisobutylate, 2.5 parts of wax powder, 70 parts of deionized water, 13 parts of PFA, 6 parts of copper sulfate.

[0031] Its preparation method comprises the following steps:

[0032] (1) Add the rare earth coupling agent into propanol, disperse evenly to prepare a coupling agent solution with a mass concentration of 1%, add copper sulfate to the coupling agent solution, heat to 90° C. and stir in a constant temperature water bath for 40 minutes. The stirring speed is 5000rpm, after stopping the stirring, use a vacuum pump to filter, wash the obtained filter cake repeatedly with distilled water, place it in an oven and dry it at 90°C for 4 hours, grind it and sieve ...

Embodiment 3

[0035] Single-component metal antirust paint, its composition in parts by weight includes: 42 parts of silicone modified styrene-acrylic emulsion, 15 parts of wollastonite powder, 3.5 parts of nano barium sulfate, 3 parts of ultrafine active magnesium hydroxide, 9 parts of propylene glycol, ethyl alcohol 3.5 parts of glycol ether, 4.5 parts of polymethacrylate, 2 parts of wax powder, 65 parts of deionized water, 15 parts of PFA, 7.5 parts of copper sulfate.

[0036] Its preparation method comprises the following steps:

[0037] (1) Add the rare earth coupling agent into propanol, disperse evenly to prepare a coupling agent solution with a mass concentration of 1%, add copper sulfate to the coupling agent solution, heat to 90° C. and stir in a constant temperature water bath for 40 minutes. The stirring speed is 5000rpm, after stopping the stirring, use a vacuum pump to filter, wash the obtained filter cake repeatedly with distilled water, place it in an oven and dry it at 90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com