Anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and polymers, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of harmful effects on the environment, poor environmental resistance of anti-corrosion coatings, easy aging and failure, etc., and achieve the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

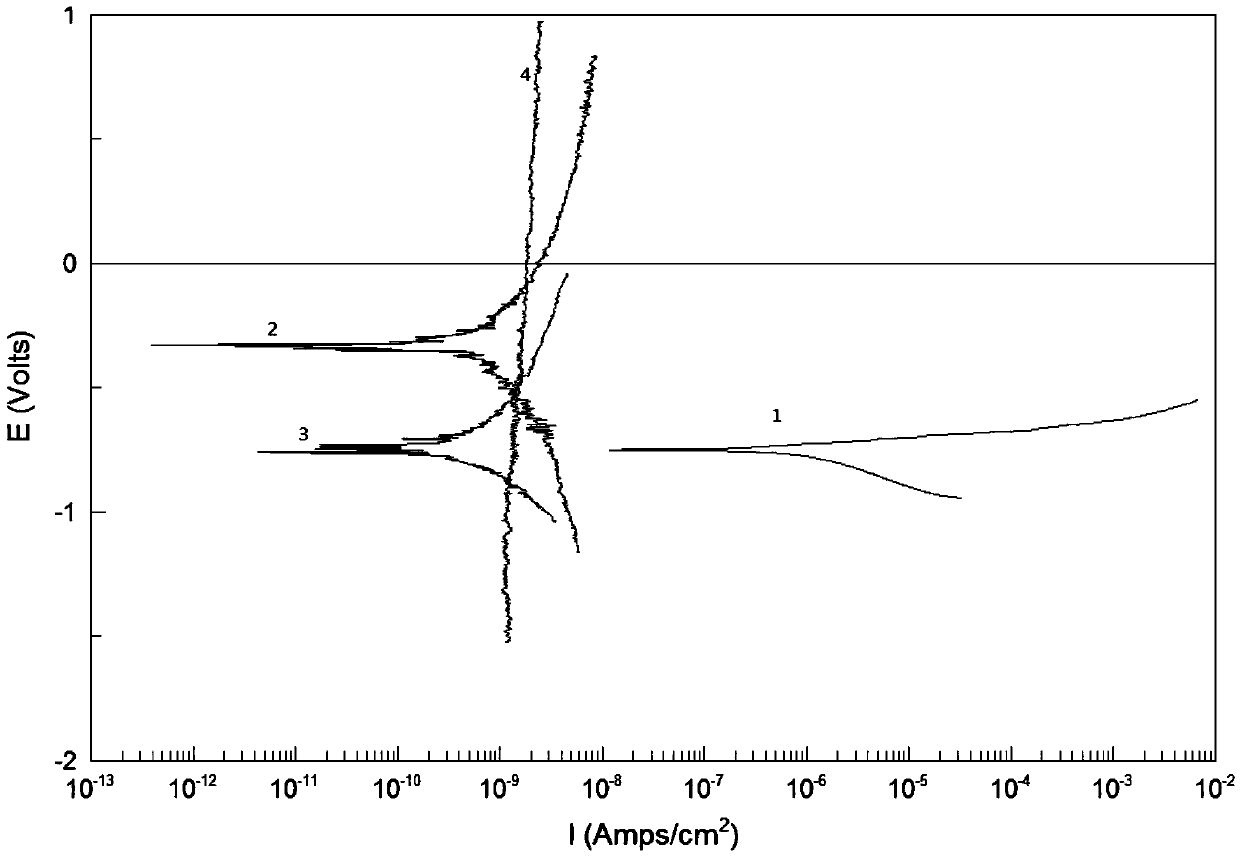

Image

Examples

Embodiment 1

[0025] 1) Take 2g graphite powder, 4.5g sodium nitrate and 30mL concentrated sulfuric acid. After stirring for 15min in an ice water bath, add 10g potassium permanganate to the mixed solution several times. After adding potassium permanganate for about 15min, remove the ice water bath. , And use a warm water bath for about 35 ℃ to keep for 4 hours; then continue to drip 115mL of deionized water to the mixed solution, about 30 minutes after dripping the deionized water, then heat the mixed solution to 98 ℃ and keep it for about 15 minutes; then, remove the heating, Add deionized water dropwise to the mixed solution to dilute it to 350 mL (about 180 mL), continue to stir for 30 minutes and then add 3.5 mL of hydrogen peroxide. After reacting for 15 minutes, centrifuge the mixed solution to wash the centrifuged product with water, and then put the washed centrifuged product at 40 Vacuum drying at ℃ for 24h to obtain graphite oxide (GTO).

[0026] The prepared 1.5 g GTO was added to ...

Embodiment 2

[0031] 1) Take 7g graphite powder, 2g sodium nitrate and 22mL concentrated sulfuric acid, stir under ice water bath for 10 minutes, add 8.5g potassium permanganate to the mixed solution several times, add potassium permanganate in about 13min, then remove the ice water bath , And use a warm water bath to keep about 38 ℃ for 3.5 hours; then continue to drop 100mL deionized water to the mixed solution, about 35 minutes to finish the dripping of deionized water, then heat the mixed solution to 96 ℃ and keep it for about 13 minutes; then remove the heating , Add deionized water dropwise to the mixed solution to dilute to 360mL, continue to stir for 35 minutes and then add 6mL of hydrogen peroxide. After 12 minutes of reaction, centrifuge the mixed solution, wash the centrifuged product with water, and then vacuum dry the washed centrifuged product at 45°C for 22h. Graphite oxide (GTO) is obtained.

[0032] The prepared 2g GTO was added to 100 mL of pH=13 sodium hydroxide solution for...

Embodiment 3

[0037] 1) Take 1.7g graphite powder, 5.5g sodium nitrate and 18mL concentrated sulfuric acid, stir for 18min in an ice-water bath, add 5g potassium permanganate to the mixed solution several times, add potassium permanganate in about 17min, then remove the ice Water bath, and use a warm water bath for about 40 ℃ to keep for 5 hours; then continue to drip 120mL deionized water to the mixed solution, drip the deionized water for about 40 minutes, then heat the mixed solution to 98 ℃ and keep it for about 15 minutes; then remove the heating , Add deionized water dropwise to the mixed solution to dilute to 340mL, then continue to stir for 30 minutes and then add 1.5mL of hydrogen peroxide. After 15 minutes of reaction, centrifuge the mixed solution, wash the centrifuged product with water, and then dry the washed centrifuged product at 35°C for 25h. Graphite oxide (GTO) is obtained.

[0038] The prepared 1.7 g of GTO was added to 100 mL of pH=12 sodium hydroxide solution for ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com