Preparation method for ultrafine-grained hard alloy striping and slitting tool

A cemented carbide, slitting knife technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of uneven distribution of Co phase, and achieve the effect of no slump, broad prospects and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

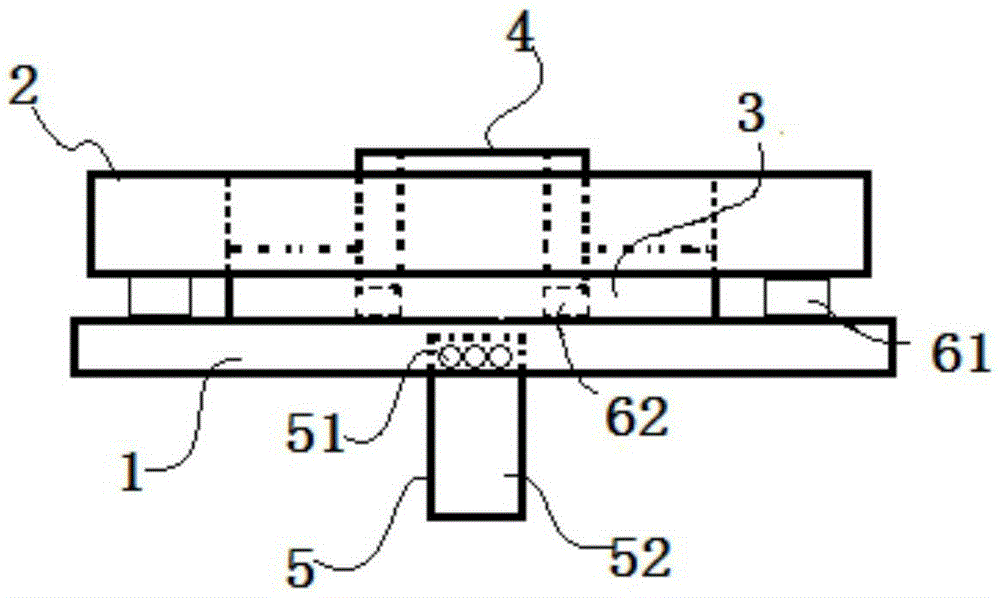

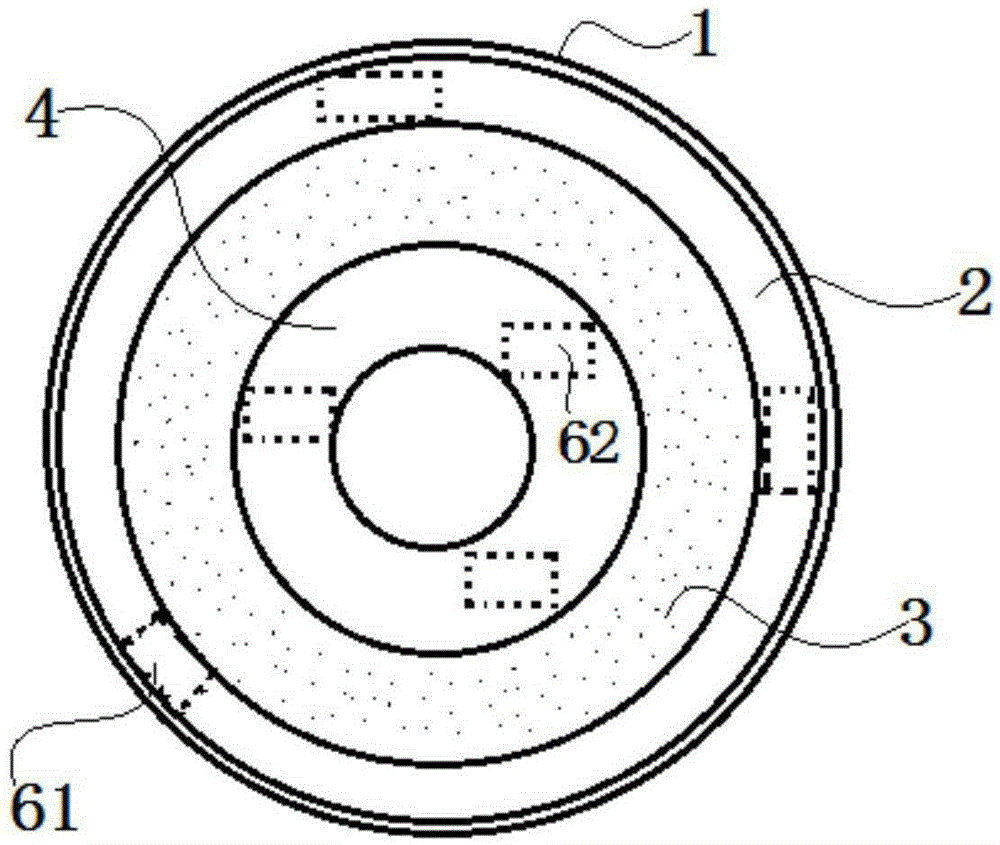

Image

Examples

Embodiment 1

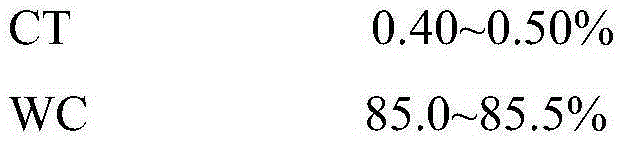

[0030] A kind of high-performance ultra-fine-grained hard alloy new material slitting and cutting knife of this embodiment, the slitting and slitting knife is made by powder metallurgy technology, and each component of its raw material is composed according to the following mass percentage: 0.45%CT , 85.2% WC, 12.3% Co, 0.5% Vc, 0.8% Cr 3 C 2 , 0.7% TaC, 0.05% octadecanoic acid. CT in the present embodiment refers to catechol, WC refers to tungsten carbide powder, Co refers to cobalt powder, Vc refers to vinylene carbonate, Cr 3 C 2 refers to chromium carbide, and TaC refers to tantalum carbide.

[0031] A kind of high-performance ultra-fine-grained hard alloy new material slitting cutter of the present embodiment, its steps are: (1) batching: each component of slitting cutter raw material is configured according to the above-mentioned components; (2) The mixed material is ground and dried, and after drying, the cloth is rotated and pressed into a compact; (3) After the co...

Embodiment 2

[0040] A kind of high-performance ultra-fine-grained cemented carbide new material slitting cutter of the present embodiment, each component of its raw material is made up of following mass percentage: 0.40%CT, 85.5%WC, 12.0%Co, 0.57%Vc, 0.7%Cr 3 C 2 , 0.8% TaC, 0.03% octadecanoic acid. Others are with embodiment 1.

Embodiment 3

[0042] A kind of high-performance ultra-fine-grained cemented carbide new material slitting cutter of the present embodiment, each component of its raw material is made up by mass percentage as follows: 0.50%CT, 85.0%WC, 12.5%Co, 0.4%Vc, 0.9%Cr 3 C 2 , 0.63% TaC, 0.07% octadecanoic acid. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com