High-efficiency and low-energy-loss nanocellulose preparation method

A nanocellulose, low-energy-consumption technology, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of cumbersome process, low efficiency and high energy consumption, and achieve the effect of simple process, low energy consumption and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

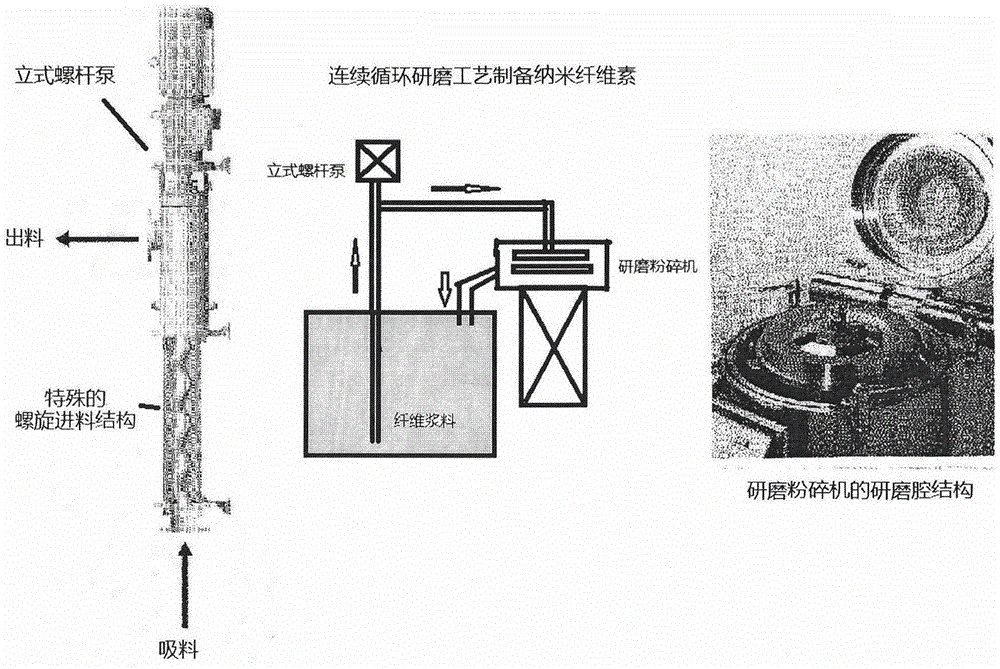

Method used

Image

Examples

Embodiment 1

[0022] 1) Cellulose pretreatment: refer to the method introduced in the non-patent literature "TEMPO-mediated surface oxidation of cellulose whiskers. Youssef Habibietal. Cellolose, 2006, 13: 679-687." to perform TEMPO-induced oxidation pretreatment on cellulose, specifically: equivalent to absolute dry weight 1000g of bleached hardwood kraft pulp fiber is wet dissociated, then diluted with water to a concentration of 1%, to which TEMPO (15.6g), NaBr (206g) and NaClO solution (available chlorine content 12%, 3725ml), use 0.5M NaOH solution to control the pH value of the reaction system to be 10.5, after reacting for 90min, add 450ml ethanol to terminate the reaction, neutralize the slurry solution with 0.5M dilute hydrochloric acid until the pH value is neutral. The carboxyl group content of measuring this oxidized slurry is 0.85mmol / g, and the hydroxyl substitution degree is 0.05. 2) Washing and concentrating: the slurry after oxidation is all transferred to a centrifugal dehy...

Embodiment 2

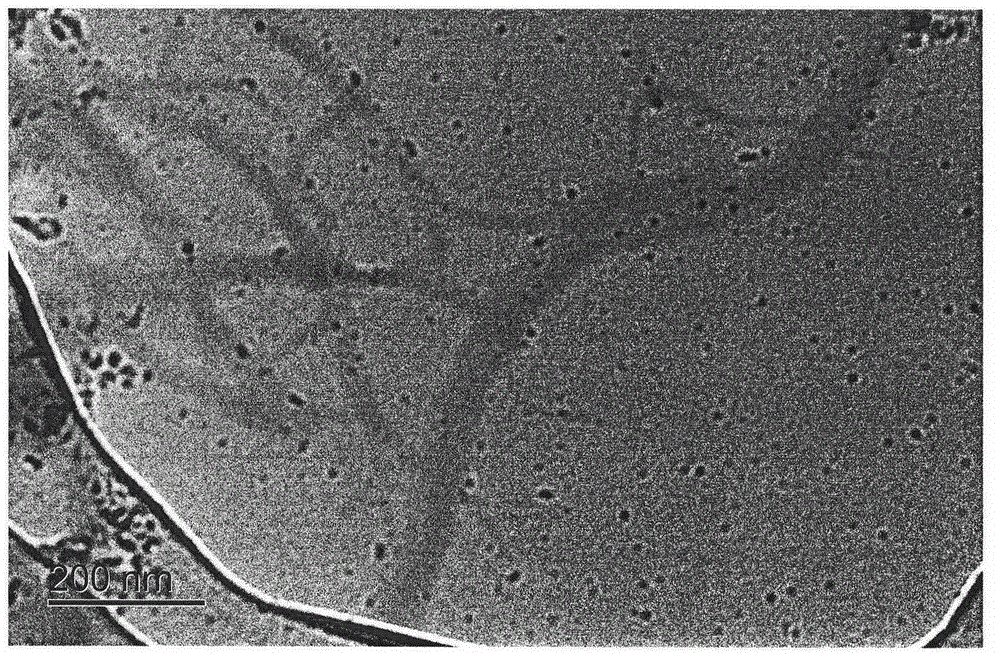

[0024] Except that the concentration of the concentrated slurry is 8.45% and the pump outlet pressure is 0.35MPa, the rest of the implementation process is the same as that of Example 1. Final preparation concentration is the high-concentration nanocellulose of 8.66%, and nanocellulose is gelatinous, and its transmission scanning electron microscope (TEM) photograph sees image 3 , Fiber diameter 20 ~ 50nm. The power consumption during the record grinding process is 0.65kWh, and the power consumption per unit product is calculated as 650kWh / t (dry pulp). The yield of nanocellulose was 84%.

Embodiment 3

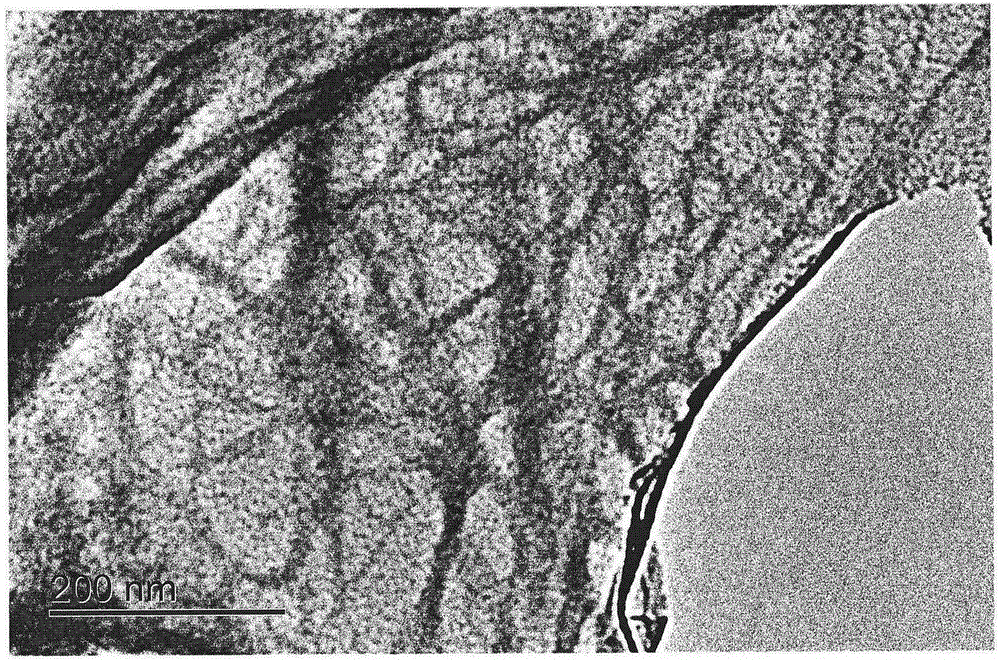

[0026] Except that the concentration of the concentrated slurry is 10.12% and the pump outlet pressure is 0.45MPa, the rest of the implementation process is the same as that of Example 1. Final preparation concentration is the high-concentration nanocellulose of 10.37%, and nanocellulose is gelatinous, and its transmission scanning electron microscope (TEM) photograph sees Figure 4 , Fiber diameter 20 ~ 50nm. The power consumption during the record grinding process is 0.53kWh, and the power consumption per unit product is calculated as 530kWh / t (dry pulp). The yield of nanocellulose was 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com