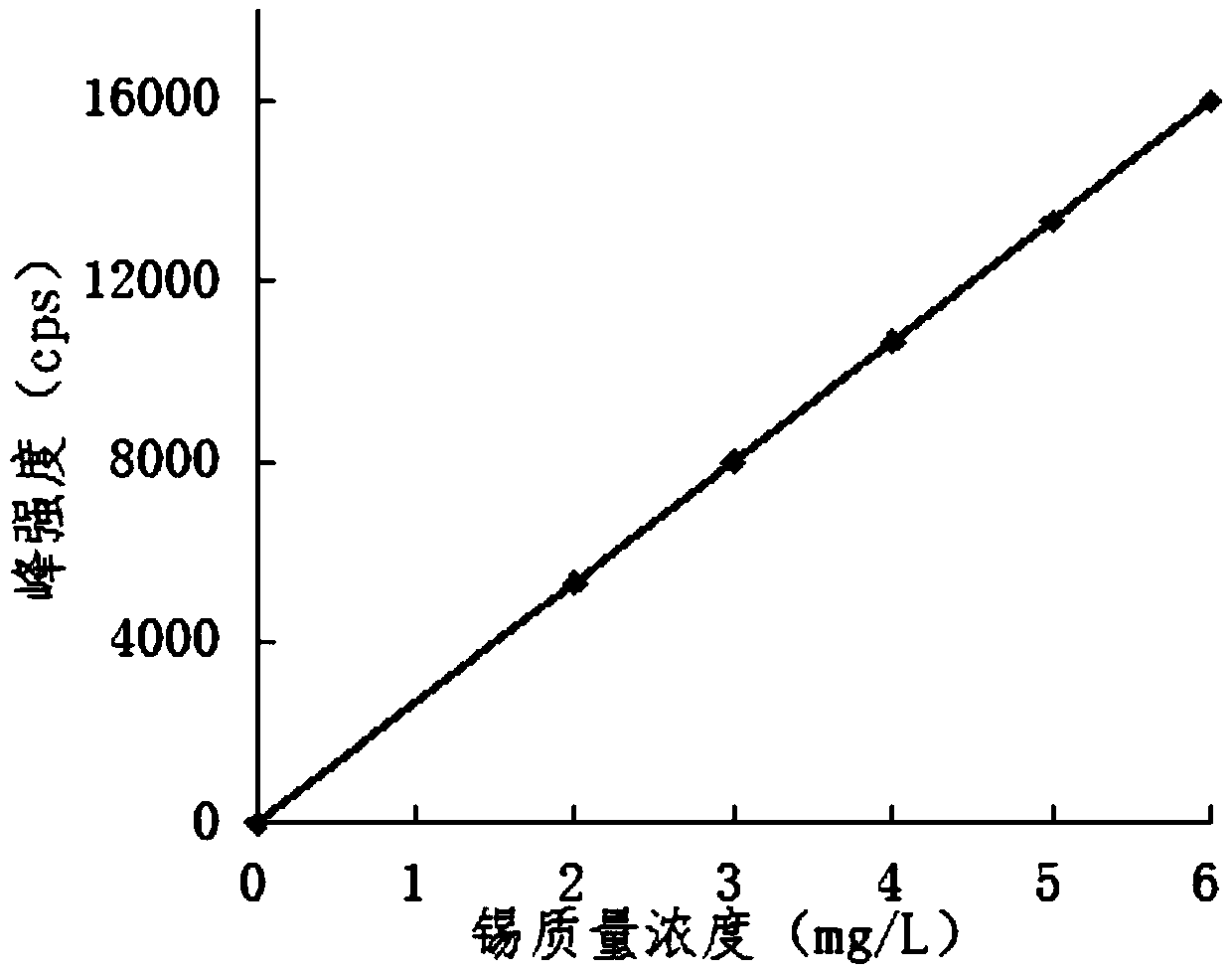

Method for measuring tin in titanium tetrachloride through ICP-AES

An ICP-AES, titanium tetrachloride technology, applied in the field of tin detection, can solve the problems of low accuracy, cumbersome procedures, and high detection cost, achieve high accuracy and precision, simple and fast operation, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for measuring tin in titanium tetrachloride with ICP-AES, comprises the following steps:

[0027] Step 1: Instrument Preparation

[0028] Start the Optima7000DV inductively coupled plasma atomic generation spectrometer, after initialization, set the working conditions according to the following parameters:

[0029] High frequency generator power: 1300w

[0030] Plasma gas flow: 10L / min

[0031] Auxiliary argon gas flow: 0.2L / min

[0032] Atomizer flow rate: 0.8L / min

[0033] Observation height: 15mm

[0034] Injection volume: 1.5mL / min

[0035] Washing time: 40s

[0036] Analysis line: 189.928nm

[0037] Step 2: Solution preparation

[0038] Step 2.1: Preparation of tin standard stock solution

[0039] Pipette 10 mL of tin standard solution with a concentration of 1000 μg / mL into a 250 mL volumetric flask, dilute to volume with ultrapure water, and shake well;

[0040] Step 2.2: Preparation of sample solution

[0041] Take 10mL, 20mL, and 30mL of hyd...

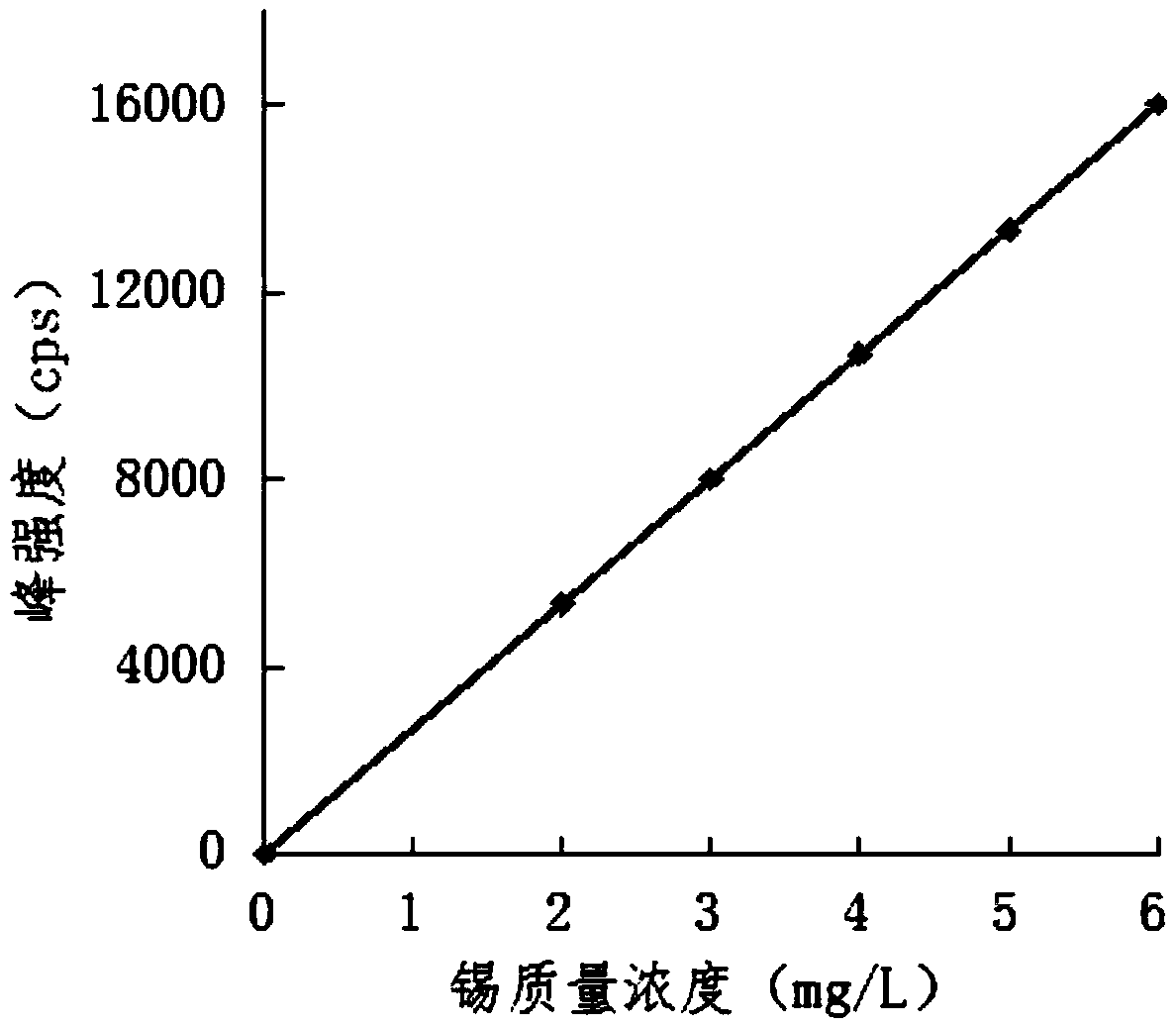

Embodiment 2

[0062] A method for measuring tin in titanium tetrachloride with ICP-AES, comprises the following steps:

[0063] Step 1: Instrument Preparation

[0064] Start the Optima7000DV inductively coupled plasma atomic generation spectrometer, after initialization, set the working conditions according to the following parameters:

[0065] High frequency generator power: 1350w

[0066] Plasma gas flow: 20L / min

[0067] Auxiliary argon gas flow: 0.25L / min

[0068] Atomizer flow rate: 0.85L / min

[0069] Observation height: 15mm

[0070] Injection volume: 1.5mL / min

[0071] Washing time: 40s

[0072] Analysis line: 189.928nm

[0073] Step 2: Solution preparation

[0074] Step 2.1: Preparation of tin standard stock solution

[0075] Pipette 10.00 mL of tin standard solution with a concentration of 1000 μg / mL into a 250 mL volumetric flask, dilute to volume with ultrapure water, and shake well;

[0076] Step 2.2: Preparation of sample solution

[0077] Take 10mL, 20mL, and 30mL o...

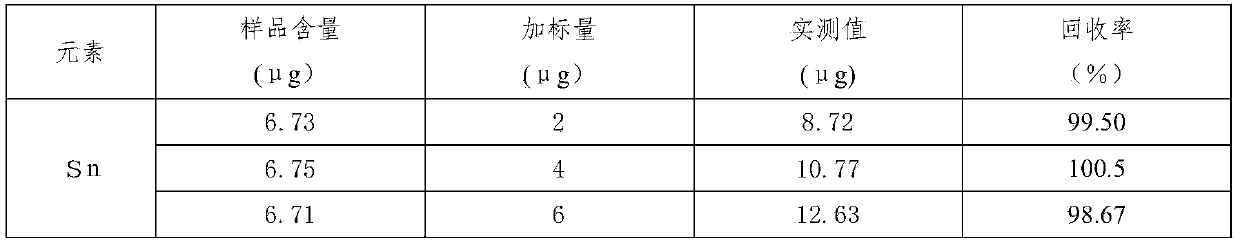

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com