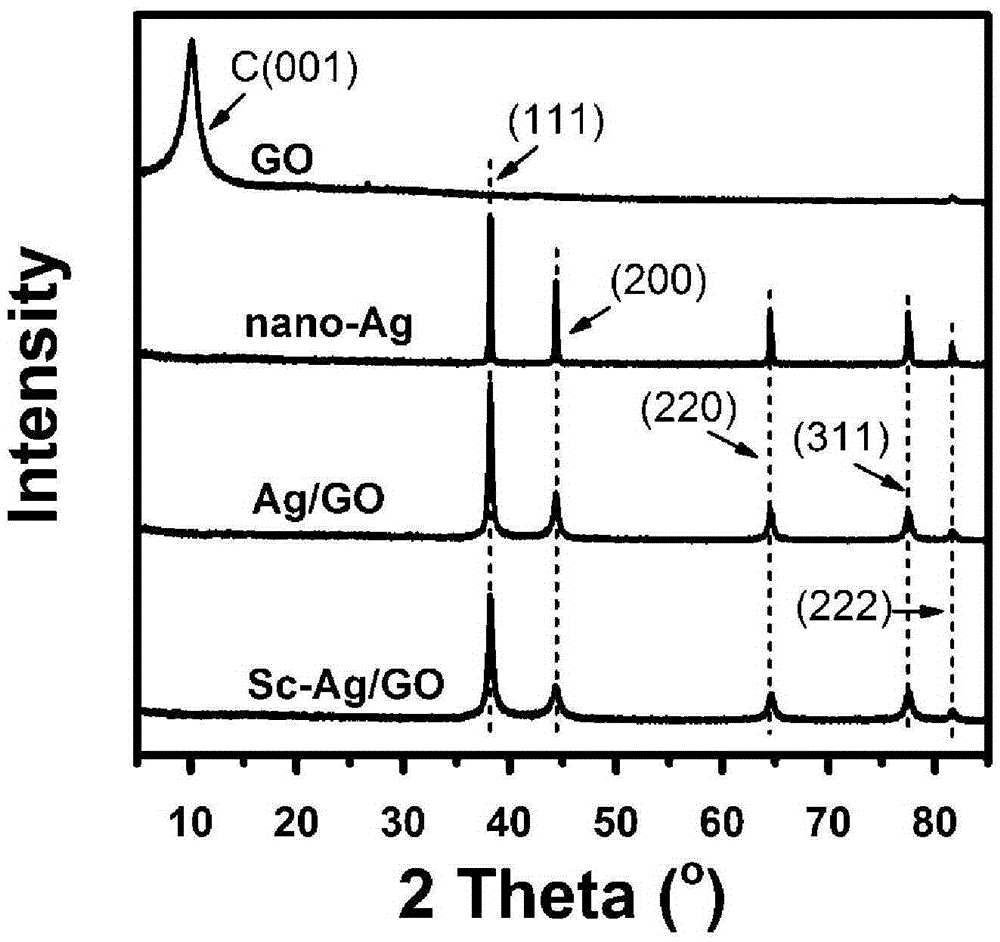

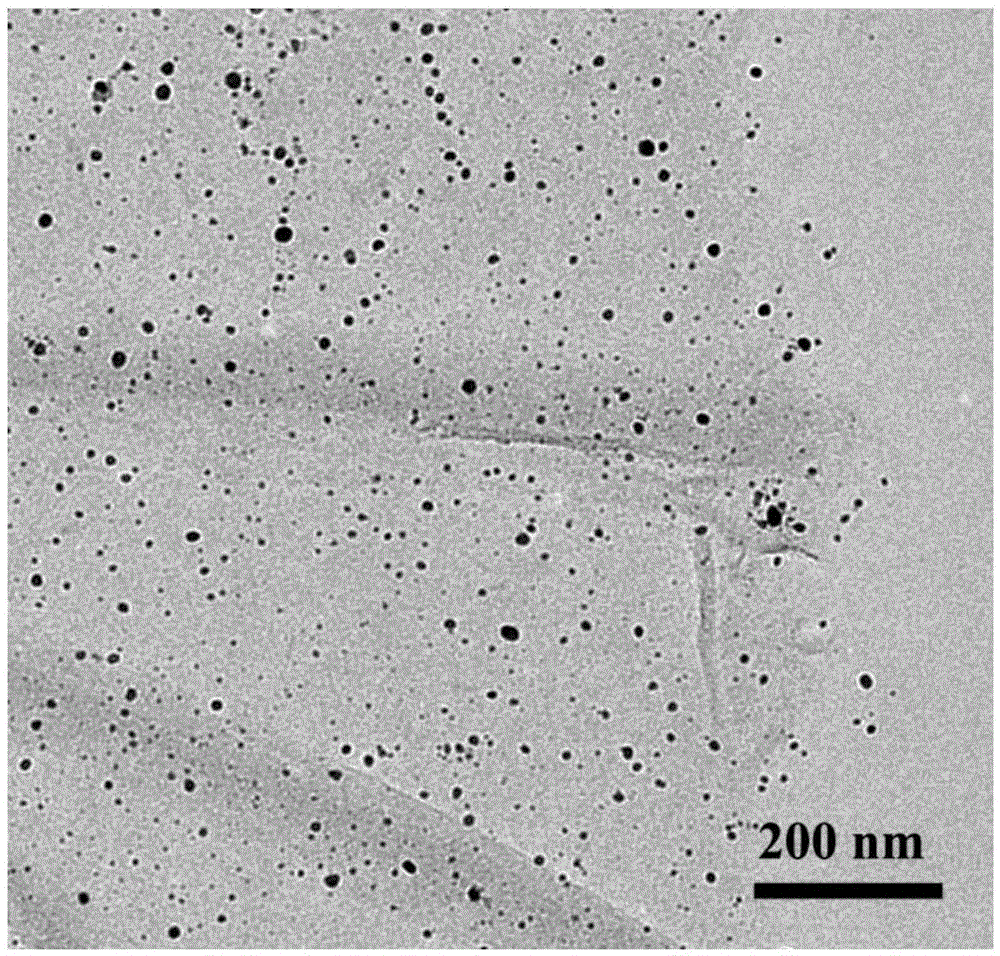

Nano-silver/graphene composite material and preparation method thereof

A composite material and graphene technology, applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of difficult control of load, low deposition rate, poor dispersion performance, etc., and achieve short process time, uniform distribution, The effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of nano silver / graphene composite material, its preparation method is as follows:

[0041] (1) At room temperature, add 100mg silver nitrate, 2ml concentrated ammonia water to 5ml deionized water to prepare silver ammonia solution, then add silver ammonia solution, 5mg sodium dodecyl sulfate (SDS), 6mg sodium citrate to 50ml anhydrous In water and ethanol, ultrasonically stir for 20 minutes to form a uniform mixed solution; then add 100 mg of graphene oxide and ultrasonically disperse for 1 hour to obtain a uniformly dispersed suspension;

[0042] (2) Dissolve 100mg of glucose in 5ml of deionized water, and mix this solution with the above mixture evenly, then quickly transfer it to a 100ml stainless steel reaction kettle, and pump in CO 2 Gas, pressurized to 8MPa and heated to 100°C;

[0043] (3) Stir and react the mixed solution in the reactor in step (2) at 300rpm for 1 hour, cool to room temperature, release the pressure and exhaust, centrifuge the precipita...

Embodiment 2

[0045] A kind of nano silver / graphene composite material, its preparation method is as follows:

[0046] (1) At room temperature, add 300mg silver nitrate and 2ml concentrated ammonia water to 5ml deionized water to prepare silver ammonia solution, then add silver ammonia solution, 10mg sodium dodecyl sulfate (SDS), 12mg sodium citrate to 50ml anhydrous In water and ethanol, ultrasonically stir for 15 minutes to form a uniform solution; then add 100 mg of graphene oxide, and ultrasonically disperse for 1.5 hours to obtain a uniformly dispersed mixed solution;

[0047] (2) Dissolve 200mg of glucose in 5ml of deionized water, and mix this solution with the above mixture evenly, then quickly transfer it to a 100ml stainless steel reaction kettle, and pump in CO 2 Gas, pressurized to 16MPa and heated to 50°C;

[0048] (3) Stir and react the mixed solution in the reaction kettle in step (2) at 550rpm for 2 hours, then cool to room temperature, release the pressure and exhaust, cen...

Embodiment 3

[0050] A kind of nano silver / graphene composite material, its preparation method is as follows:

[0051] (1) At room temperature, add 600mg silver nitrate and 2ml concentrated ammonia water to 5ml deionized water to prepare silver ammonia solution, then add silver ammonia solution, 15mg sodium dodecyl sulfate (SDS), 18mg sodium citrate to 50ml anhydrous In water and ethanol, ultrasonically stir for 10 minutes to form a uniform solution; then add 100 mg of graphene oxide, and ultrasonically disperse for 1 hour to obtain a uniformly dispersed mixed solution;

[0052] (2) Dissolve 400mg of glucose in 5ml of deionized water, and mix this solution with the above mixture evenly, then quickly transfer it to a 100ml stainless steel reaction kettle, and pump in CO 2 Gas, pressurized to 12MPa and heated to 75°C;

[0053] (3) Stir and react the mixed solution in the reaction kettle in step (2) at 800rpm for 0.5 hours, then cool to room temperature, release the pressure and exhaust, cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com