Preparation method and application of photoelectrochemical aptamer sensing electrode

A photoelectrochemical and sensing electrode technology, applied in the direction of material electrochemical variables, etc., can solve the problems of low selectivity and sensitivity, long response time, complex instruments, etc., and achieve the effect of low detection cost, high sensitivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The preparation method of BiOBr-NG nanocomposites is as follows: 0.12g bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in deionized water, with nitric acid (HNO 3 ) solution to adjust its pH value to 3. In addition, 0.8mg NG was dispersed in CTAB solution and mixed evenly by ultrasonic. Then Bi(NO 3 ) 3 ·5H 2 The O solution was slowly dropped into the mixed solution of NG and CTAB. The above mixture was transferred to a round bottom flask and reacted in an oil bath at 60°C for 3h. After the reaction was completed, the prepared precipitate was repeatedly washed three times with ethanol and deionized water, and dried at 80°C for future use.

[0032] Wherein, the volume of the solvent deionized water used is 50mL, CTAB and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O was 1:1, the ultrasonic mixing time was 0.5 h, and the concentration of CTAB was 8×10 -3 mol / L.

[0033] (2) Surface pretreatment of ITO electrode: Boil the ITO electrode with 1M sodium ...

Embodiment 2

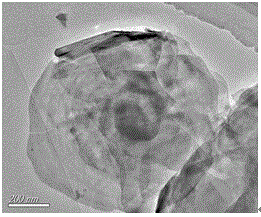

[0037](1) The preparation method of BiOBr-NG nanocomposites is as follows: 0.12gBi(NO 3 ) 3 ·5H 2 O dissolved in deionized water, with nitric acid (HNO 3 ) solution to adjust its pH value to 3. In addition, 1.56 mg was dispersed in CTAB solution and ultrasonically mixed. Then Bi(NO 3 ) 3 ·5H 2 The O solution was slowly dropped into the mixed solution of NG and CTAB. The above mixture was transferred to a round bottom flask and reacted in an oil bath at 80°C for 3h. After the reaction was completed, the prepared precipitate was repeatedly washed three times with ethanol and deionized water, and dried at 80°C for later use. figure 1 is the transmission electron microscope image of the synthesized BiOBr-NG nanocomposite, by figure 1 It can be seen that the flaky BiOBr is dispersed on the NG graphene sheet.

[0038] Wherein, the volume of the solvent deionized water used is 50mL, CTAB and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O was 1:1, the ultrasonic mixing time was 0....

Embodiment 3

[0043] (1) The preparation method of BiOBr-NG nanocomposites is as follows: 0.12gBi(NO 3 ) 3 ·5H 2 O dissolved in deionized water, with nitric acid (HNO 3 ) solution to adjust its pH value to 3, in addition, 4.5mg NG was dispersed in CTAB solution and ultrasonically mixed. Then Bi(NO 3 ) 3 ·5H 2 The O solution was slowly dropped into the mixed solution of NG and CTAB. The above mixture was transferred to a round bottom flask and reacted in an oil bath at 120°C for 3h. After the reaction was completed, the prepared precipitate was repeatedly washed three times with ethanol and deionized water, and dried at 80°C for future use.

[0044] Wherein, the volume of the solvent deionized water used is 50mL, CTAB and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O was 1:1, NG, ultrasonic mixing time was 0.5h, and the concentration of CTAB was (8×10 -3 mol / L).

[0045] (2) Surface pretreatment of ITO electrode: Boil the ITO electrode with 1M sodium hydroxide for 15-20 minutes, then ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com