Method for catalyzed preparation of C5 petroleum resin by utilizing boron trifluoride

A technology of boron trifluoride and petroleum resin, which is applied in the field of boron trifluoride catalyzed preparation of C5 petroleum resin, can solve the problems of wide coverage, roughness, and insufficient disclosure, and achieve good adaptability, high conversion rate, and improved resin Effect of Molecular Weight and Softening Point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

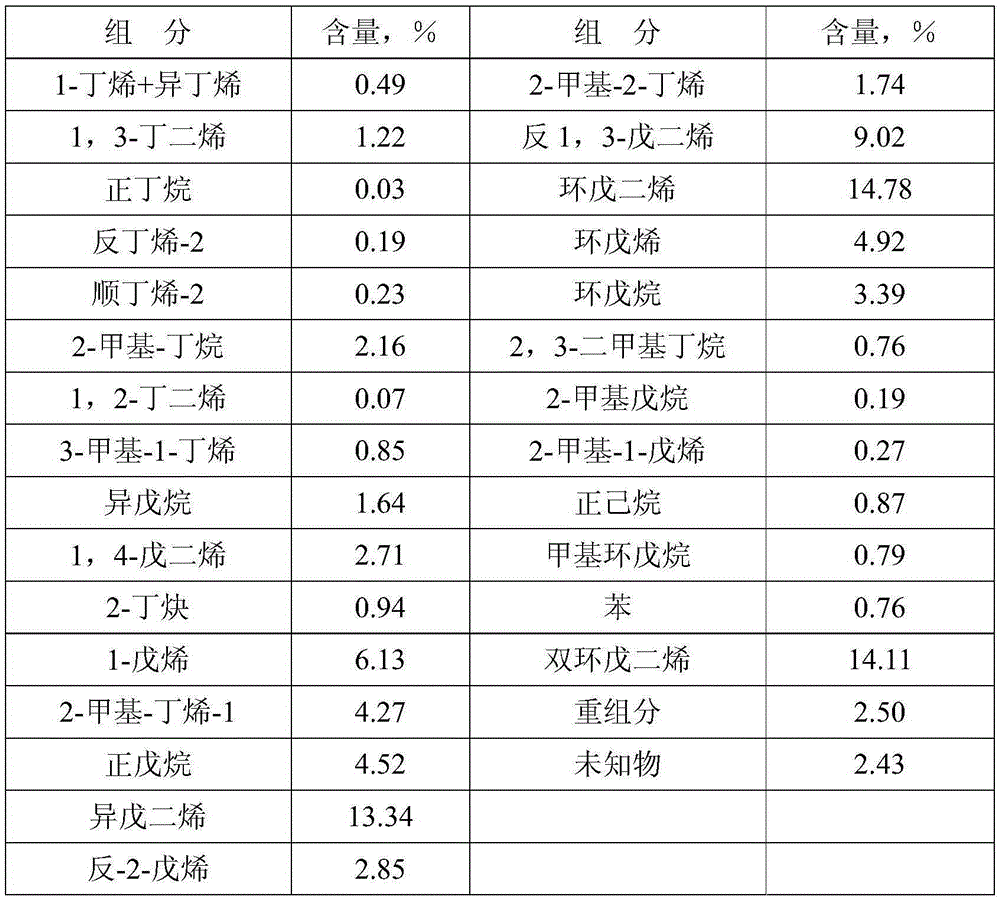

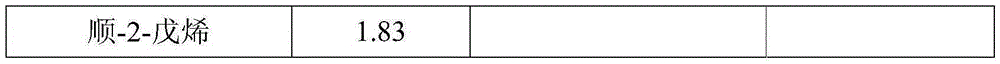

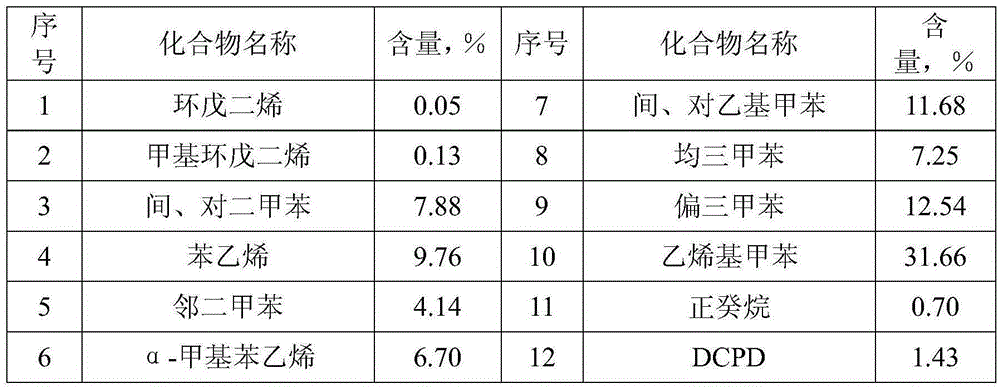

Embodiment 1

[0042] The C5 fraction is rectified to obtain a boiling point of 20-70°C as the polymerization raw material A, and the enriched material of styrene, α-methylstyrene and vinyltoluene is used as the polymerization raw material B, and the raw material A, raw material B and saturated hydrocarbons Solvent C is uniformly mixed according to the mass ratio of 1:0.5:1 to obtain ingredient D, and its components are: 6.0wt% isopentene, 8.0wt% isoprene, 20.0wt% piperylene, and 2.0wt% cyclopentadiene , 6.0wt% cyclopentene, 1.2wt% 1-hexene, 2.0wt% styrene, 1.6wt% α-methylstyrene, 8.0wt% vinyltoluene, and the rest are C5-C10 mixed hydrocarbons;

[0043] In a reaction kettle with a stirrer, pre-put into the saturated hydrocarbon solvent accounting for 50% of the total mass of the reaction material, then slowly dropwise add the ingredient D accounting for 49.5% of the total mass of the reaction material, and continuously add 0.5wt% of the total mass of the material boron trifluoride catalyst, ...

Embodiment 2

[0045]The C5 fraction is rectified to obtain a boiling point of 20-70°C as the polymerization raw material A, and the enriched material of styrene, α-methylstyrene and vinyltoluene is used as the polymerization raw material B, and the raw material A, raw material B and saturated hydrocarbons Solvent C is uniformly mixed according to the mass ratio of 1:0:1.5 to obtain ingredient D, and its composition is: 6.0wt% isopentene, 8.0wt% isoprene, 20.0wt% piperylene, and 2.0wt% cyclopentadiene , 6.0wt% cyclopentene, 1.2wt% 1-hexene, and the rest are C5-C10 mixed hydrocarbons;

[0046] In a reaction kettle with a stirrer, pre-put into the saturated hydrocarbon solvent accounting for 50% of the total mass of the reaction material, then slowly dropwise add the ingredient D accounting for 49.5% of the total mass of the reaction material, and continuously add 0.5wt% of the total mass of the material boron trifluoride catalyst, after the feeding, the reaction materials were reacted at 130°...

Embodiment 3

[0048] The C5 fraction is rectified to obtain a boiling point of 20-70°C as the polymerization raw material A, and the enriched material of styrene, α-methylstyrene and vinyltoluene is used as the polymerization raw material B, and the raw material A, raw material B and saturated hydrocarbons Solvent C is uniformly mixed according to the mass ratio of 1:0:1.5 to obtain batching D, its composition is: 5.2wt% isopentene, 4.8wt% isoprene, 15.2wt% piperylene, 1.6wt% cyclopentadiene , 6.0wt% cyclopentene, 0.5wt% 1-hexene, and the rest are C5-C10 mixed hydrocarbons;

[0049] In a reaction kettle with a stirrer, pre-put into the saturated hydrocarbon solvent accounting for 50% of the total mass of the reaction material, then slowly dropwise add the ingredient D accounting for 48.5% of the total mass of the reaction material, and continuously add 1.5wt% of the total mass of the material boron trifluoride ether catalyst, after feeding, let the reaction materials react at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com