Polycaprolactone silk fibroin electrospun fiber membrane with continuous lamellar micro-nano structure on the surface and its preparation method and application

A technology of micro-nano structure and polycaprolactone, applied in the field of nano-materials, can solve problems such as poor mechanical properties and degradation ability, and obstacles to biomedical applications, so as to increase the surface area of fibers and increase the possibility of changing from hydrophobicity to hydrophilicity High efficiency and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

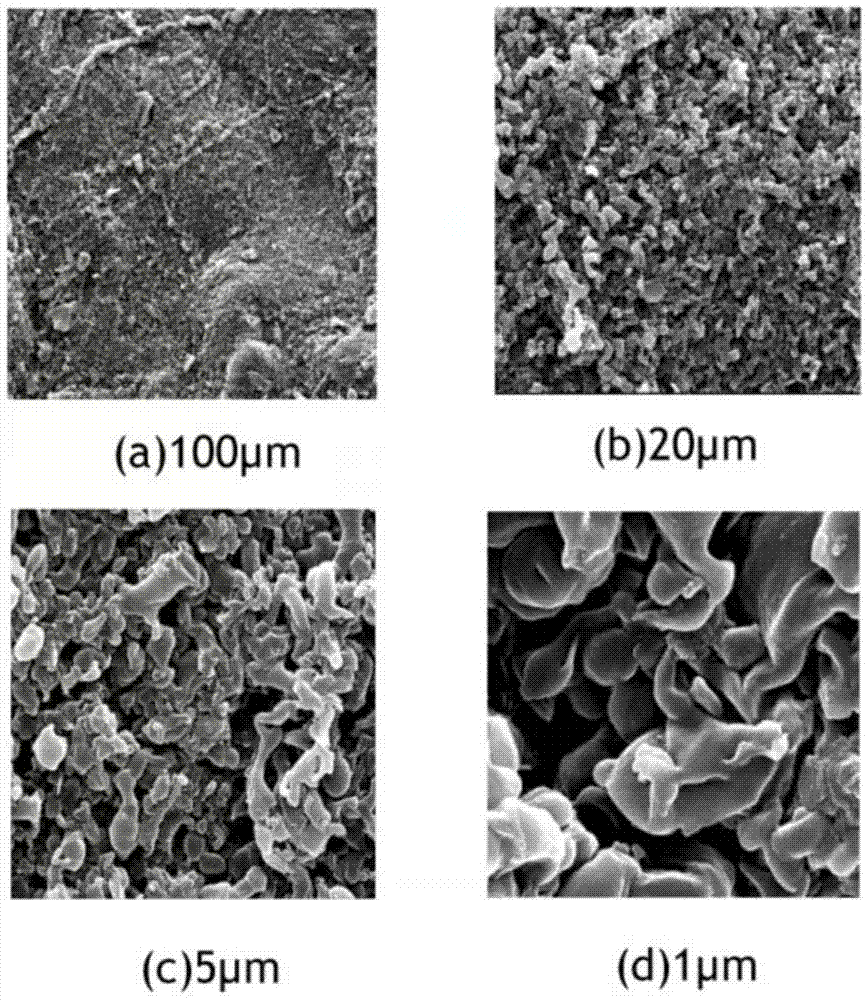

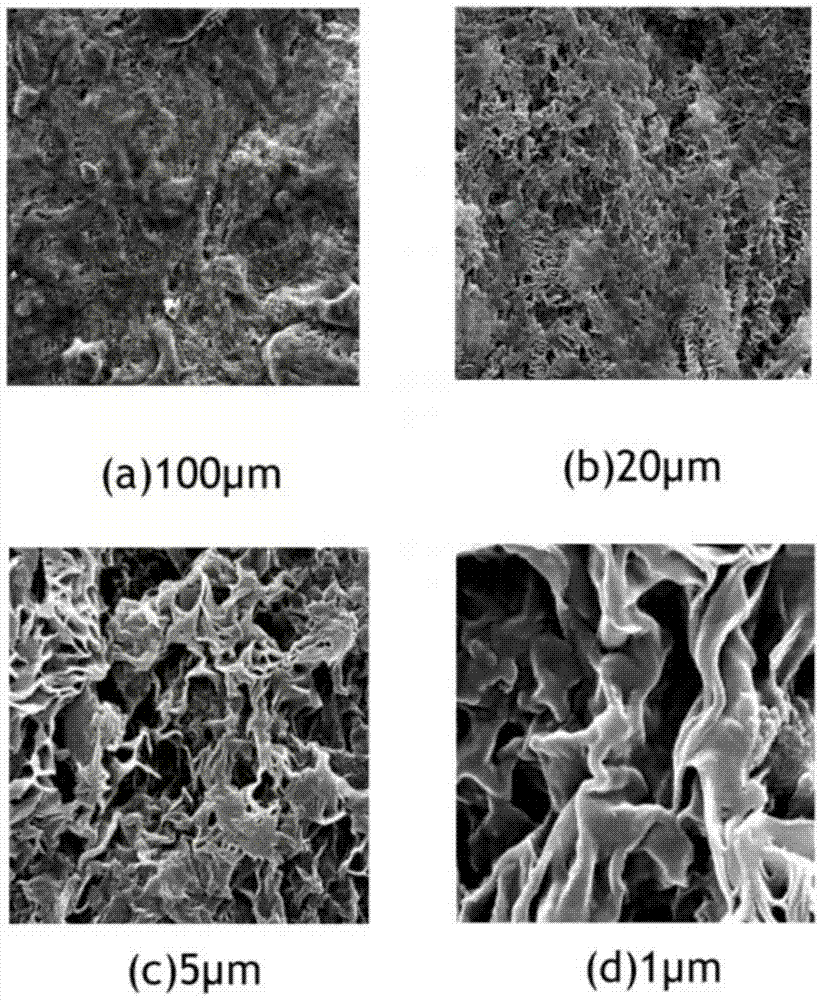

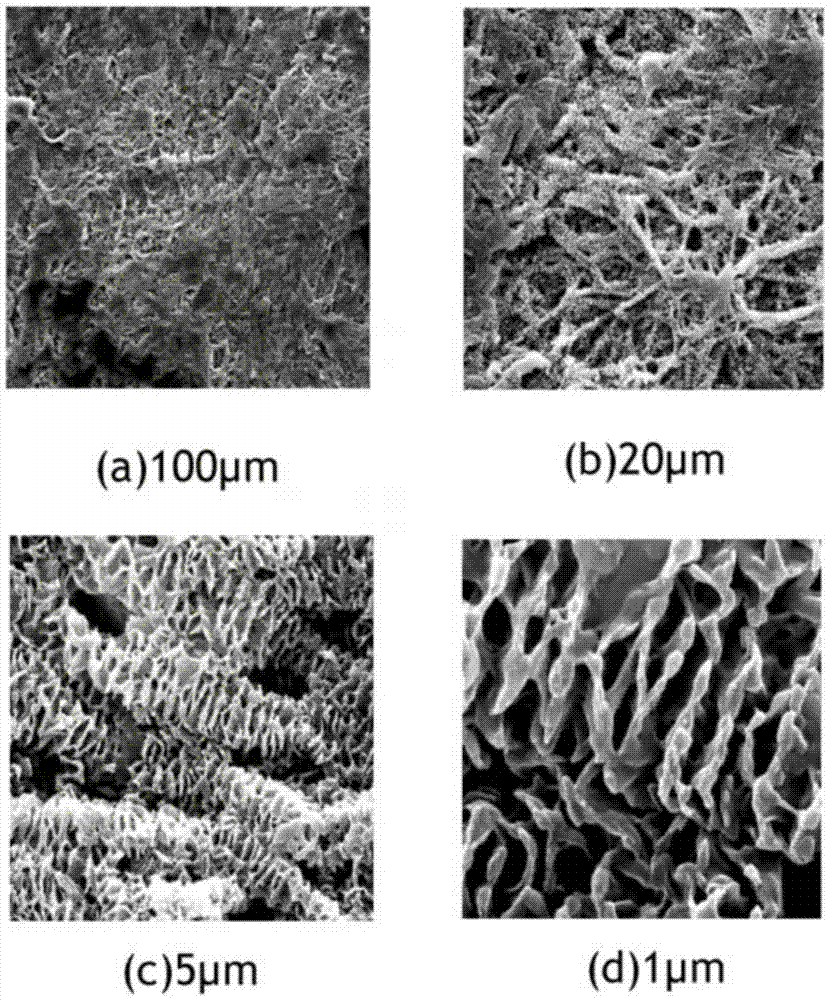

[0036] Step (1) Put the natural silk in a sodium bicarbonate (0.5wt%) aqueous solution and boil it for 30 minutes, take it out, rinse it with deionized water for 3 times, and repeat the above steps 3 times. Place the degummed silk in a vacuum drying oven at 40°C for 48 hours in vacuum;

[0037] Dissolve 0.3 g of silk and 0.7 g of polycaprolactone particles in 10 ml of hexafluoroisopropanol solvent, and stir at a constant speed for 6 hours at room temperature until the silk and polycaprolactone are completely dissolved to obtain a mixed solution;

[0038] Step (2) Put the mixed solution in a 20ml syringe, exhaust the air, fix it on a dual-channel micro-syringe pump, set the rate at 2.0ml / h, connect the metal needle of the syringe to a high-voltage electrostatic field, and perform electrospinning at room temperature. Electrospinning parameters are: spinning distance 15-20cm; spinning voltage 18-20kV; booster pump flow rate 1.8-2.2ml / h, electrospinning the mixed solution at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com