Capacitive concentration difference power generation technology

A capacitive and capacitor electrode technology, applied in the field of capacitive concentration difference power generation, can solve the problems of high production cost of membrane, easy to be corroded, and large device, and achieve the effects of low cost, simple device and small device area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

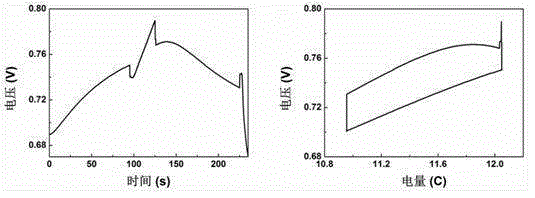

[0039] Example 1: Electric double layer capacitive concentration difference power generation technology

[0040] The electric double layer type electrochemical capacitor is used in this embodiment, that is, the ion storage mechanism is the adsorption and desorption of the electric double layer.

[0041] The capacitor is composed of a current collector, a positive electrode, a diaphragm and a negative electrode; the current collector is made of conductive graphite paper; the diaphragm is a layer of non-woven fabric. Electrolyte is sodium chloride aqueous solution, concentration is 1g / L and 30g / L respectively. Both the positive and negative electrodes are made of YP50 activated carbon (Kuraray Chemical Co., LTD, Japan), with a specific surface area of 1600m 2 / g.

[0042] YP50 activated carbon, conductive carbon black, and binder are mixed in a ball mill at a mass ratio of 8:1:1. The solvent is N-methylpyrrolidone (NMP), and the mass percentage of YP50 activated carbon is ...

Embodiment 2

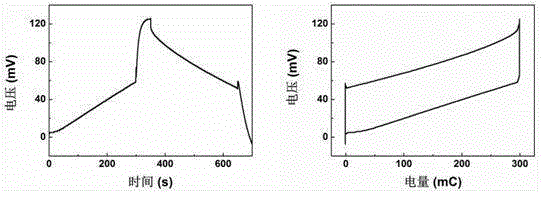

[0051] Example 2: Hybrid Capacitive Concentration Power Generation Technology

[0052] In this embodiment, a hybrid electrochemical capacitor is used, that is, the positive and negative electrodes have different ion storage mechanisms, the positive electrode is a Faraday reaction mechanism, and the negative electrode is an electric double layer adsorption mechanism.

[0053] The capacitor is composed of a current collector, a positive electrode, a diaphragm and a negative electrode; the current collector is made of conductive graphite paper; the diaphragm is a layer of non-woven fabric. The electrolyte is sodium chloride aqueous solution, dilute brine and concentrated brine with concentration of 1g / L and 30g / L respectively.

[0054] In the present embodiment, the positive electrode material selects sodium manganese oxide Na 4 mn 9 o 18 The negative electrode material is YP50 activated carbon (Japan Kuraray Chemical Co., LTD), with a specific surface area of 1600m 2 / g....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com