A kind of lithium-ion battery flexible packaging film

A lithium-ion battery and flexible packaging film technology, applied in the field of packaging, can solve problems such as electrolyte leakage, potential safety hazards, and reduce the bonding strength of aluminum foil and heat-sealing layer, so as to prevent deterioration, long service life, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

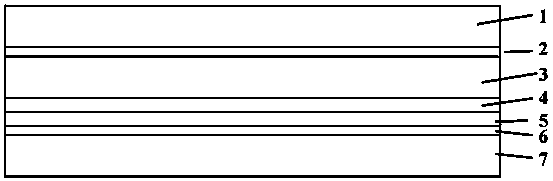

Image

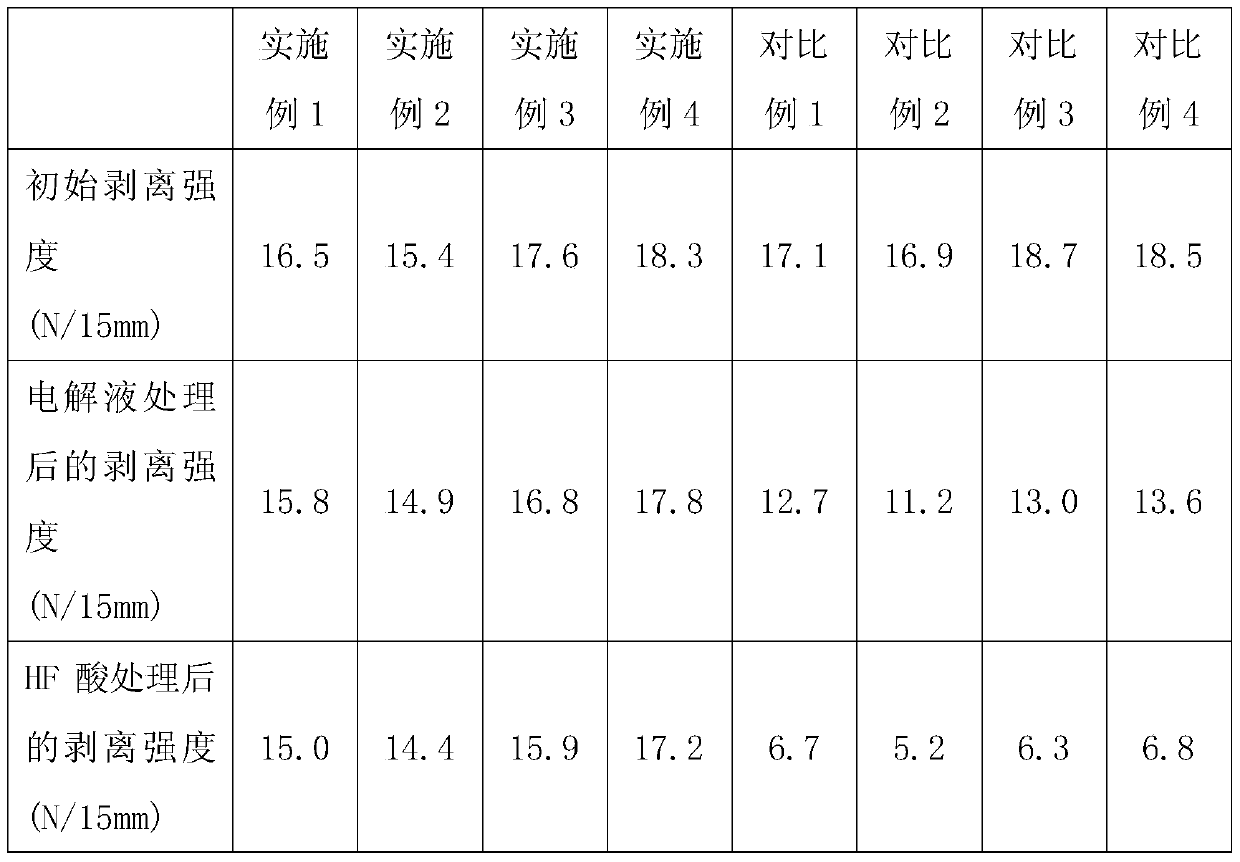

Examples

Embodiment 1

[0042] 1) Prepare a passivation layer of titanium and zirconium salts on a 50 μm thick iron-containing aluminum foil;

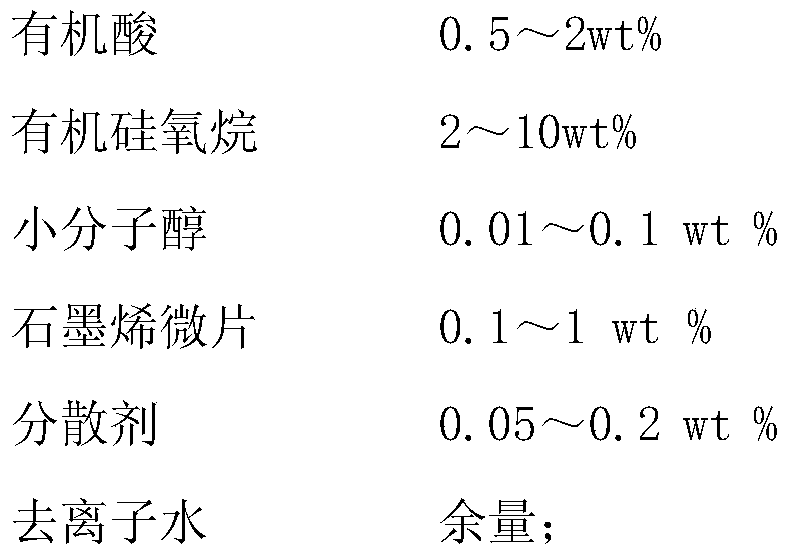

[0043] 2) Prepare graphene / siloxane coating solution

[0044] Prepare 970g of acid solution with pH=4.5 with acetic acid and sodium acetate in advance, slowly add 30 grams of siloxane KH550 to the acid solution under stirring conditions, add 0.2 grams of glycerin, stir well, and place it at room temperature for one day;

[0045] Add 1 gram of single-layer pure graphene microflakes with a width of 0.5-1.0 μm, an oxygen content of 0, and an aspect ratio of 500-1000 and 0.5 gram of polyacrylic acid with a molecular weight of 1000 into the siloxane solution, and ultrasonically disperse them evenly , standing still for 3 to 4 hours to obtain a coating solution.

[0046] 3) Preparation of graphene oxide / siloxane physical barrier layer

[0047] The coating solution was evenly coated on the surface of the passivation layer of the aluminum foil by using a gravure co...

Embodiment 2

[0050] 1) Prepare a passivation layer of titanium and zirconium salts on a 45 μm thick iron-containing aluminum foil;

[0051] 2) Prepare graphene / siloxane coating solution

[0052] Prepare 900g of acid solution with pH=3 with carboxysuccinic acid and sodium dodecylbenzenesulfonate in advance, slowly add 90g of siloxane KH550 into the acid solution under stirring condition, add 0.9g of ethanol, stir well, and place at room temperature one day;

[0053] Add 4g of pure graphene microflakes with a width of 2-3μm, an oxygen content of 0 and an aspect ratio of 300-1500 and 1g of polyethylene oxide with a molecular weight of 5000 into the siloxane solution, and ultrasonically disperse them evenly. After standing still for 3 to 4 hours, a coating liquid was obtained.

[0054] 3) Preparation of graphene oxide / siloxane physical barrier layer

[0055] The coating solution was uniformly coated on the surface of the aluminum foil passivation layer by using a gravure coater, and heat-tr...

Embodiment 3

[0058] 1) Prepare a passivation layer of titanium and zirconium salts on a 40 μm thick iron-containing aluminum foil;

[0059] 2) preparing graphene / siloxane coating solution;

[0060] Prepare 950g of acid solution with pH=3.5 with acetic acid and sodium lauryl sulfate in advance, slowly add 50g of siloxane KH560 into the acid solution while stirring, add 0.3g of 1,3-propanediol, stir evenly, and place it at room temperature for one day ;

[0061] Add 2 g of graphene oxide microflakes with a width of 2 to 3 μm, an oxygen content of 40 to 45 wt%, and an aspect ratio of 300 to 1500 and 1.5 g of hydroxypropyl methylcellulose with a molecular weight of 8000 into the siloxane solution , ultrasonically disperse evenly, and stand still for 3 to 4 hours to obtain a coating liquid.

[0062] 3) Preparation of graphene oxide / siloxane physical barrier layer

[0063] The coating solution was evenly coated on the surface of the passivation layer of the aluminum foil by using a gravure co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com