Lithium battery positive-pole material, preparation method thereof and lithium-ion battery containing positive-pole material

A technology of lithium ion battery and positive electrode material, which is applied in the field of lithium battery positive electrode material, can solve the problems of low electronic conductivity and low lithium ion conductivity of the coating, achieve good lithium ion conductivity, improve cycle stability and rate performance , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also relates to a preparation method of the spinel lithium nickel manganese oxide positive electrode material with a composite coating layer, which at least includes the following three steps:

[0037] (1) mixing the spinel lithium nickel manganese oxide positive electrode material with a zirconium-containing compound, a lanthanum-containing compound and a lithium salt;

[0038] Wherein: zirconium-containing compounds are selected from Zr(OH) 4 , ZrOCl 2 , ZrO 2 , ZrCl 4 , ZrF 4 At least one of; lanthanum-containing compounds selected from La 2 o 3 、LaCl 3 、LaF 3 At least one of; Lithium salt is selected from LiOH, Li 2 CO 3 At least one of them; the molar ratio of the zirconium-containing compound to the spinel lithium nickel manganese oxide positive electrode material is 10 -4 ~0.1:1, the molar ratio of lanthanum-containing compound to zirconium-containing compound is 0.5-2:1, the molar ratio of lithium salt to zirconium-containing comp...

Embodiment 1~4

[0044] A kind of spinel lithium nickel manganese oxide positive electrode material with composite cladding layer, the surface of the spinel lithium nickel manganese oxide positive electrode material has Li 7 La 3 Zr 2 o 12 and LiNbO 3 Composite coating layer, wherein the structure formula of spinel lithium nickel manganese oxide cathode material is LiM x+y Ni 0.5-x mn 1.5-y o 4 , M is one or more of Co, Al, Cr, Fe, Mg, Zr, Ti, 0≤x<0.5, 0≤y<1.5.

[0045] The preparation method of the lithium battery cathode material is as follows:

[0046] (1) fully mixing the spinel lithium nickel manganese oxide positive electrode material with zirconium-containing compound, lanthanum-containing compound and lithium salt;

[0047] (2) Mix and sinter the uniformly mixed samples to obtain Li-containing 7 La 3 Zr 2 o 12 The spinel lithium nickel manganese oxide positive electrode material of the first cladding layer;

[0048] (3) spinel lithium nickel manganese oxide with the first ...

Embodiment 5~8

[0066] A kind of spinel lithium nickel manganese oxide positive electrode material with composite cladding layer, the surface of the spinel lithium nickel manganese oxide positive electrode material has Li 7 La 3 Zr 2 o 12 and LiNbO 3 Composite coating layer, wherein the structure formula of spinel lithium nickel manganese oxide cathode material is LiM x+y Ni 0.5-x mn 1.5-y o 4 , M is one or more of Co, Al, Cr, Fe, Mg, Zr, Ti, 0≤x<0.5, 0≤y<1.5.

[0067] The procedure for preparing the positive electrode material for lithium batteries is the same as in Example 3, and the specific parameters are shown in Table 2.

[0068] Table 2:

[0069]

[0070]

[0071] The spinel lithium nickel manganese oxide positive electrode material with composite coating layer prepared according to the above specific parameters has similar rate performance and cycle stability as the positive electrode material in Example 3.

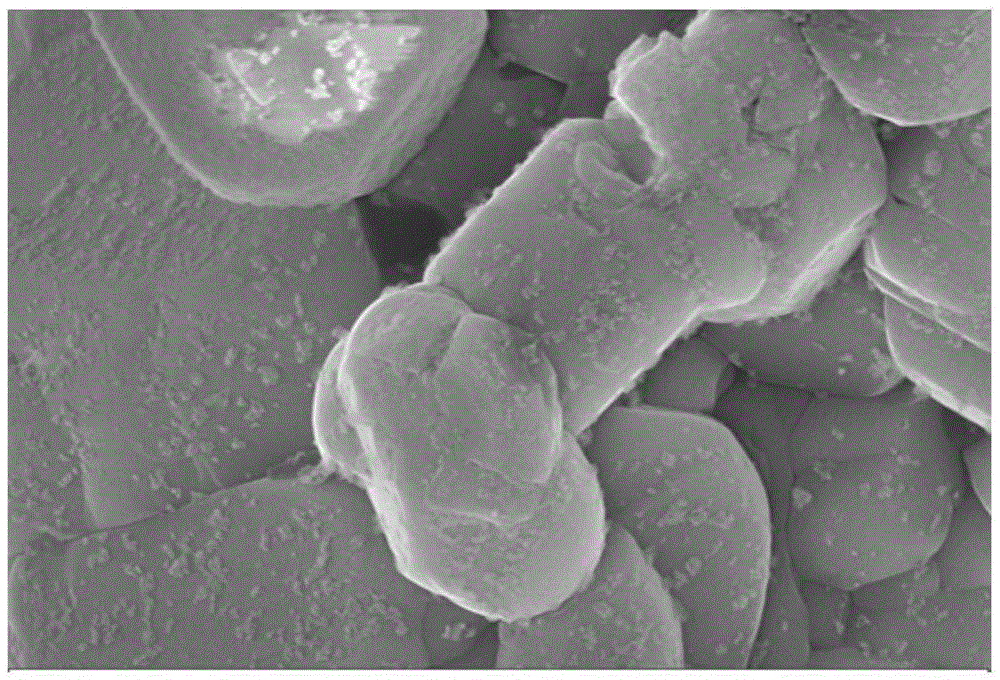

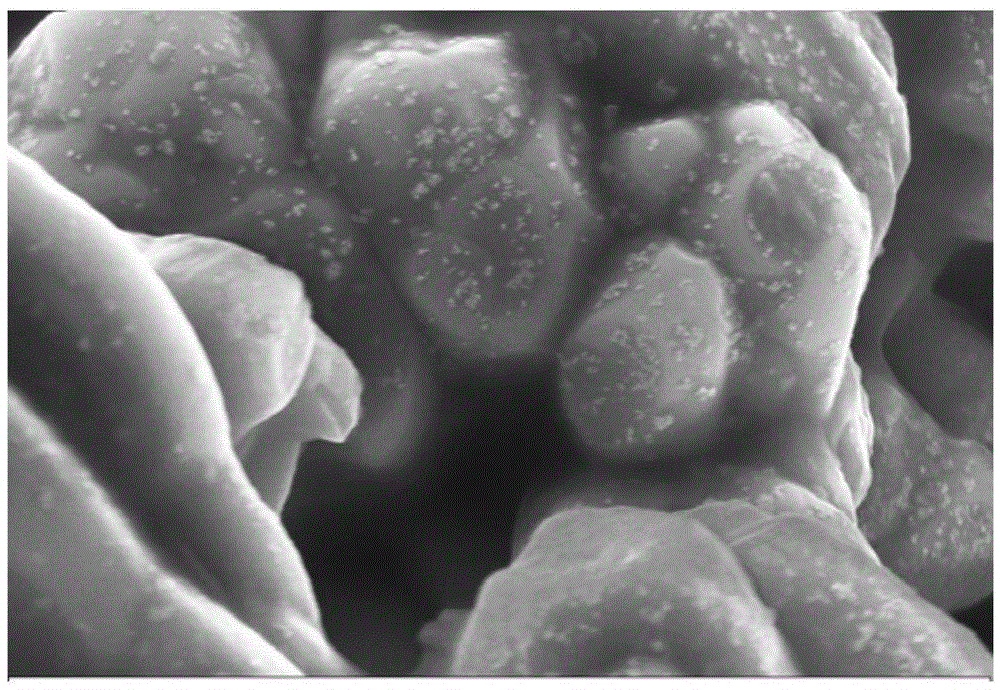

[0072] Such as Figure 7 with Figure 8 Shown, adopt the lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com