Mine acid wastewater utilization and deep purification method

A technology for deep purification of mine acid wastewater, applied in chemical instruments and methods, zinc sulfate, multi-stage water treatment, etc., can solve problems such as being unsuitable for high-concentration acid wastewater treatment, poor metal ion tolerance, and low treatment efficiency. , to achieve the effect of simple facilities, reduced environmental risks, and efficient enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

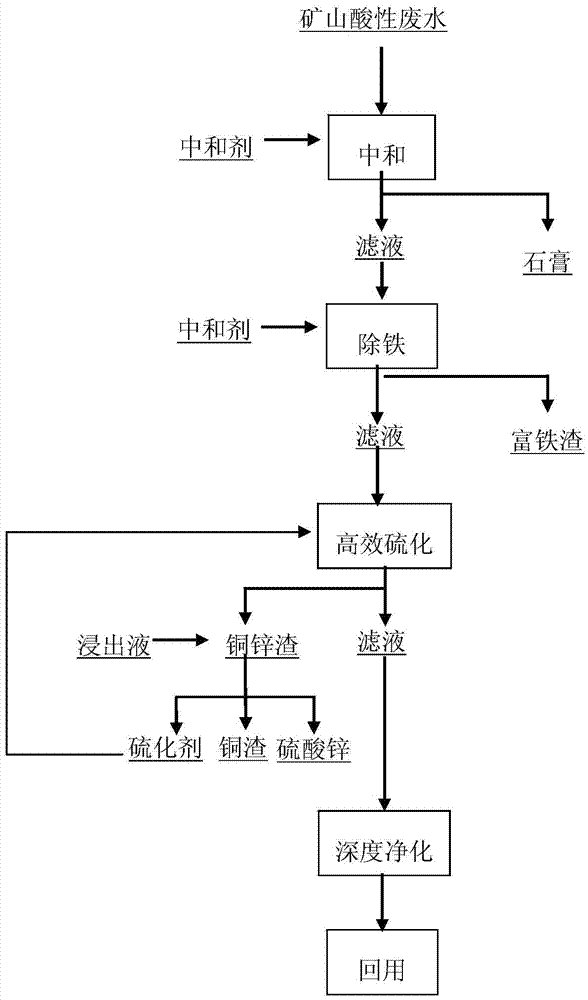

Method used

Image

Examples

Embodiment 1

[0030] The sample was taken from the raffinate wastewater of a gold and copper mine smelting company, with an acidity of 0.33mol / L, a copper ion content of 85mg / L, a zinc ion content of 204mg / L, and a total iron ion content of 8.6g / L. Follow the steps below:

[0031] 1) Use a neutralizer to adjust the pH value of the acidic mine wastewater to 2.2, and then separate the solid and liquid to obtain gypsum;

[0032] 2) Use a neutralizer to adjust the pH value of the acidic mine wastewater to 3.2, remove iron ions, and recover iron slag;

[0033] 3) adding a vulcanizing agent to the solution after iron removal to obtain copper-zinc slag;

[0034] 4) Copper-zinc slag is separated to obtain copper-rich slag and zinc sulfate solution after acid leaching, and reclaims vulcanizing agent;

[0035] 5) Advanced treatment of the final effluent.

[0036] The neutralizing agent of steps 1) and 2) is calcium carbonate.

[0037] In step 3), the molar ratio of vulcanizing agent sodium sulfid...

Embodiment 2

[0042] The sample was taken from the raffinate wastewater B / D of a gold and copper mine smelting company, with an acidity of 0.41mol / L, a copper ion content of 584mg / L, a zinc ion content of 216mg / L, and a total iron ion content of 8.3g / L. Follow the steps below:

[0043] 1) Use a neutralizer to adjust the pH value of the mine acid wastewater to 2.4, and then separate the solid and liquid to obtain gypsum;

[0044] 2) Use a neutralizer to adjust the pH value of the mine acid wastewater to 3.0, remove iron ions, and recover iron slag;

[0045] 3) adding a vulcanizing agent to the solution after iron removal to obtain copper-zinc slag;

[0046] 4) Copper-zinc slag is separated to obtain copper-rich slag and zinc sulfate solution after acid leaching, and reclaims vulcanizing agent;

[0047] 5) Advanced treatment of the final effluent.

[0048] The neutralizing agent in step 1) and 2) is calcium carbonate, sodium carbonate, magnesium carbonate, calcium oxide, magnesium oxide. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com