Wear resistant anti-vibration pad material for automobile and preparation method thereof

A technology for vibration damping pads and automobiles, applied in the field of rubber materials, can solve the problems of vehicle vibration, affecting the vibration damping effect, aging, etc., and achieve the effects of good wear resistance, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

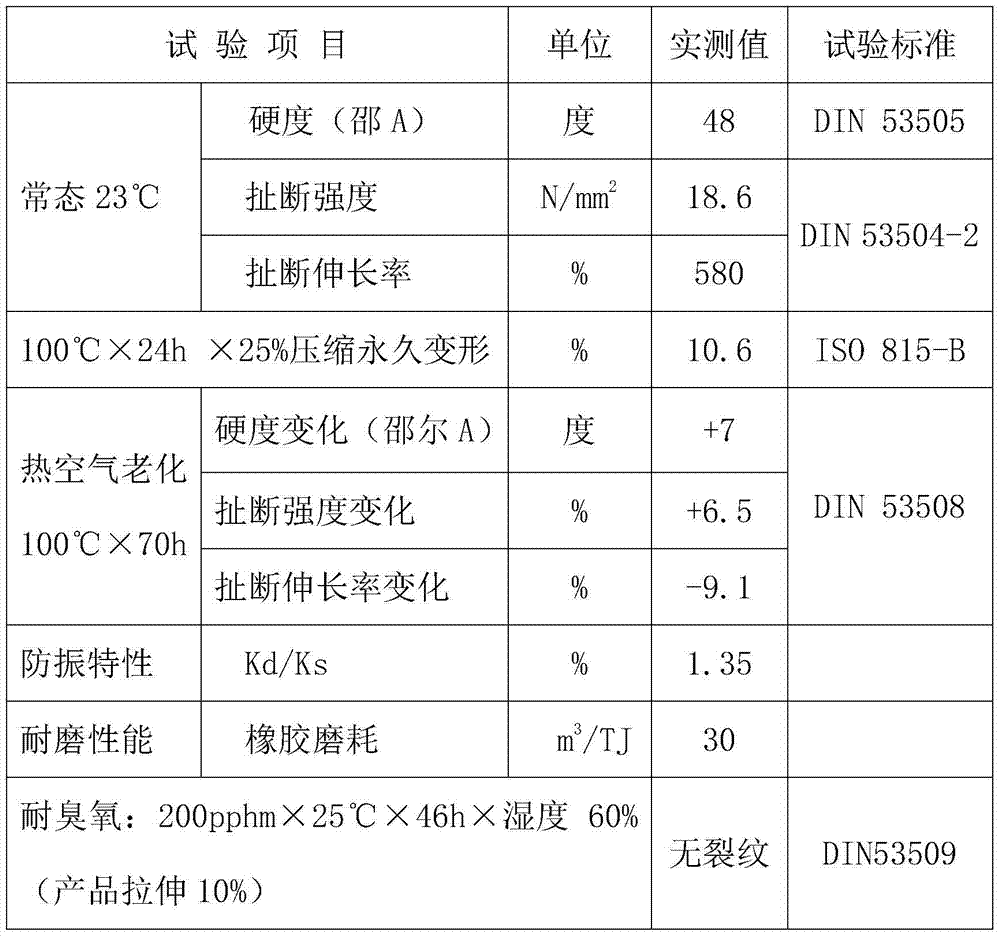

Image

Examples

Embodiment 1

[0026]A kind of wear-resisting anti-vibration pad material for automobile, its raw material comprises by weight: 40 parts of nitrile rubber, 35 parts of grafted modified natural rubber, 20 parts of styrene-butadiene rubber, 16 parts of modified wood flour, 4 parts of sodium bentonite 15 parts of superfine talc powder, 1 part of coupling agent, 12 parts of nano-silica, 6 parts of light calcium, 6 parts of magnesium oxide, 0.2 parts of stearic acid, 15 parts of epoxy soybean oil, epoxy silkworm chrysalis oleic acid 5 parts of butyl ester, 0.3 parts of sulfur powder, 1.5 parts of vulcanizing agent DCP, 3 parts of triallyl isocyanurate, 0.3 parts of accelerator CZ, 1 part of tributyl citrate, 0.3 parts of antioxidant RD 0.3 part, 0.3 part of anti-aging agent NBC, 5 parts of operating oil;

[0027] Wherein, the preparation method of the modified wood powder comprises: heating 20-mesh wood powder at 230°C until the water content is ≤3wt%, to obtain dry wood powder; adding mixed buty...

Embodiment 2

[0034] A kind of wear-resisting anti-vibration pad material for automobile, its raw material comprises by weight: 60 parts of nitrile rubber, 25 parts of grafted modified natural rubber, 30 parts of styrene-butadiene rubber, 8 parts of modified wood flour, 10 parts of sodium bentonite 5 parts, superfine talc powder 5 parts, coupling agent 3 parts, nano white carbon black 4 parts, light calcium 13 parts, magnesium oxide 3 parts, stearic acid 0.5 parts, epoxy soybean oil 5 parts, epoxy silkworm chrysalis oleic acid 15 parts of butyl ester, 0.1 part of sulfur powder, 2 parts of vulcanizing agent DCP, 1 part of triallyl isocyanurate, 0.5 part of accelerator CZ, 0.5 part of tributyl citrate, 0.6 part of anti-aging agent RD, 0.1 part of anti-aging agent NBC, 10 parts of operating oil;

[0035] Wherein, the preparation method of the modified wood powder comprises: heating 60-mesh wood powder at 190°C until the water content is ≤3wt%, to obtain dry wood powder; adding mixed butyl acry...

Embodiment 3

[0042] A kind of wear-resisting anti-vibration pad material for automobile, its raw material comprises by weight: 45 parts of nitrile rubber, 33 parts of grafted modified natural rubber, 22 parts of styrene-butadiene rubber, 14 parts of modified wood flour, 6 parts of sodium bentonite 12 parts of superfine talc powder, 1 part of coupling agent, 10 parts of nano-silica, 8 parts of light calcium, 5 parts of magnesium oxide, 0.3 parts of stearic acid, 12 parts of epoxy soybean oil, epoxy silkworm chrysalis oleic acid 7 parts of butyl ester, 0.3 parts of sulfur powder, 1.6 parts of vulcanizing agent DCP, 2 parts of triallyl isocyanurate, 0.4 parts of accelerator CZ, 0.9 parts of tributyl citrate, 0.4 parts of antioxidant RD parts, 0.3 parts of anti-aging agent NBC, 7 parts of operating oil;

[0043] Wherein, the preparation method of the modified wood powder comprises: heating 40-mesh wood powder at 210°C until the water content is ≤3wt%, to obtain dry wood powder; adding mixed bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com