Preparation method of anti-mite and antibacterial regenerative cellulosic fibers

A technology of regenerated cellulose and fiber, applied in the direction of wet spinning, artificial filament made of viscose, etc., can solve the problems of high cost, affecting the quality of the fiber itself, cumbersome preparation process, etc., achieve low toxicity and benefit the body Healthy, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of viscose spinning solution

[0025] The raw material is cotton pulp with a degree of polymerization of 500-600, and its cellulose content is greater than 90%, and the glue is made according to the following process route: dipping, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and defoaming.

[0026] The viscose spinning solution made according to the above-mentioned process has a cellulose content of 8.8%, a NaOH mass fraction of 5.9%, a viscosity of (falling ball method) 58s, and a degree of maturity of (10%NH 4 Cl) 8.6 mL.

[0027] Preparation of Microcapsule Dispersion System

[0028] In the reaction kettle, a microcapsule dispersion system with a mass fraction of 10% was prepared with distilled water, neem oil and nano-TiO in the capsule core 2 The composition ratio of the rosehip oil is 10:4:86, and a relatively uniform microcapsule dispersion can be obtained by adding tristearin dispersant accounting for 1% of the mass o...

Embodiment 2

[0042] Preparation of viscose spinning solution

[0043]The raw material is wood pulp with a polymerization degree of 500-600, and its cellulose content is greater than 90%, and the glue is made according to the following process route: impregnation, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and defoaming.

[0044] The viscose spinning solution made according to the above-mentioned process has a cellulose content of 9.0%, a NaOH mass fraction of 5.8%, a viscosity of (falling ball method) 60s, and a degree of maturity of (10%NH 4 Cl) 8.9 mL.

[0045] Preparation of Microcapsule Dispersion System

[0046] In the reaction kettle, microcapsule dispersion systems with mass fractions of 5%, 10%, 15%, 20%, and 25% were prepared with distilled water, neem oil, nano-TiO 2 The component ratio of olive oil and olive oil is 12:3:85, add glyceryl tristearate dispersant accounting for 2% of the mass of microcapsules, and stir well to obtain a relatively uni...

Embodiment 3

[0054] Preparation of viscose spinning solution

[0055] The raw material is bamboo pulp with a degree of polymerization of 500-600, and its cellulose content is greater than 90%, and the glue is made according to the following process route: dipping, pressing, crushing, aging, yellowing, continuous dissolution, filtration, and defoaming.

[0056] The viscose spinning solution made according to the above-mentioned process has a cellulose content of 8.9%, a NaOH mass fraction of 6.0%, a viscosity of (falling ball method) 59s, and a degree of maturity of (10%NH 4 Cl) 8.7 mL.

[0057] Preparation of Microcapsule Dispersion System

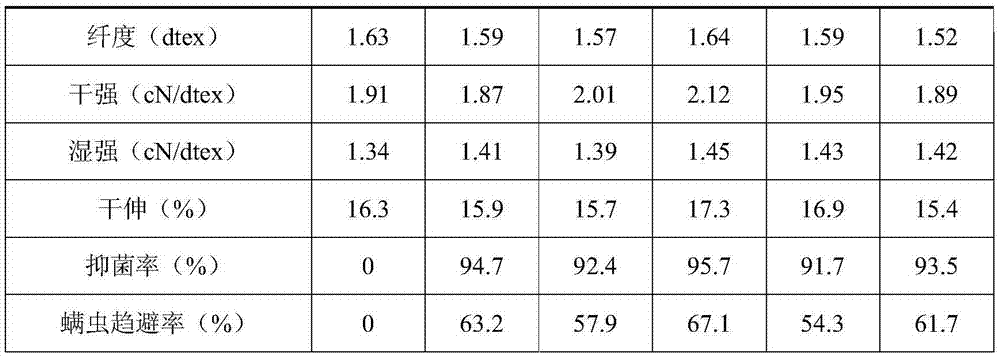

[0058] In the reaction kettle, a microcapsule dispersion system with a mass fraction of 20% was prepared with distilled water, and the mass ratio of neem oil and wheat germ oil in the capsule core was 10:90, adding 0%, 1%, and 2% of the mass of the microcapsules , 3%, 4%, 5% sodium hexametaphosphate dispersant, fully stirred to obtain a relatively un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com