Inversed high-voltage light emitting diode (LED) chip electrode and chip fabrication method

A LED chip, high-voltage technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of motor blocking light-emitting drive life, uneven current diffusion, poor stability, etc., to reduce the current from the convergence effect, reduce light Decrease, enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

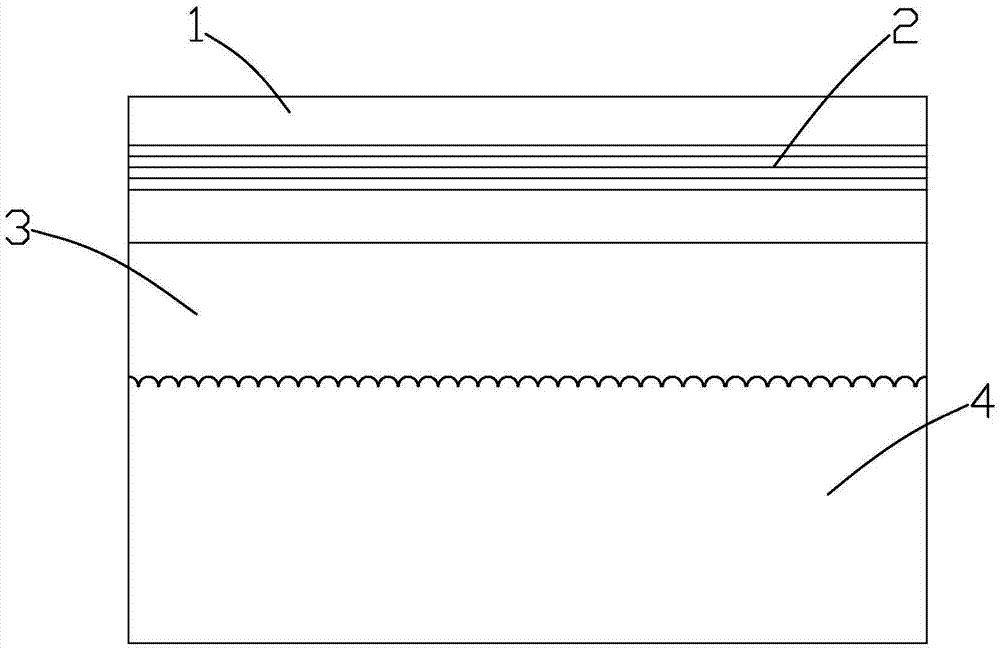

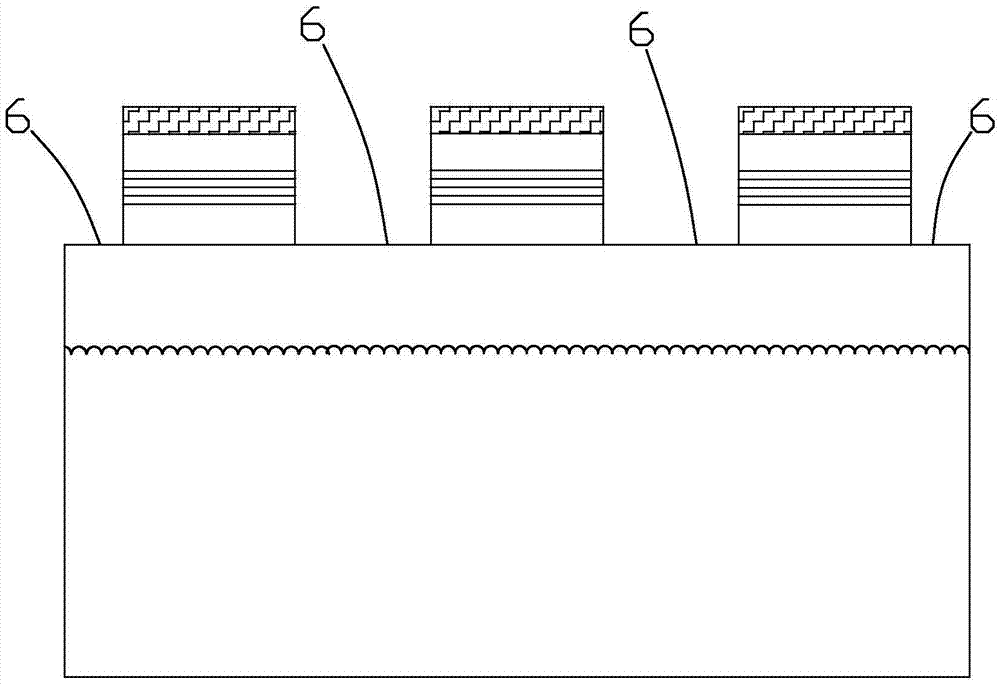

[0049] A method for manufacturing a flip-chip high-voltage LED chip as described above includes the following steps:

[0050] (1) Treat the substrate

[0051] Thinning, grinding and CMP polishing the back of the epitaxial wafer substrate grown on GaN to reduce its thickness from 430 μm to 180 μm, surface flatness (TTV) ≤ 50 μm, warpage (BOW) ≤ 50 μm, average roughness Degree S a ≤0.2nm;

[0052] (2) Clean the epitaxial layer

[0053] Pickle the light gallium nitride epitaxial wafer on which the chip is made, and wash it with aqua regia (HCl: HNO 3 =3:1) Imaging and etching for 30 minutes, mainly cleaning and removing metal pollutants on the wafer surface; 2 SO 4 :H 2 o 2 = 1:4 wash at room temperature for 5 minutes, mainly to remove surface organic contamination; then use HF:H 2 O (DI, ultrapure water) = 1: 1 to remove the oxide layer on the wafer surface, and finally rinse and dry with deionized water;

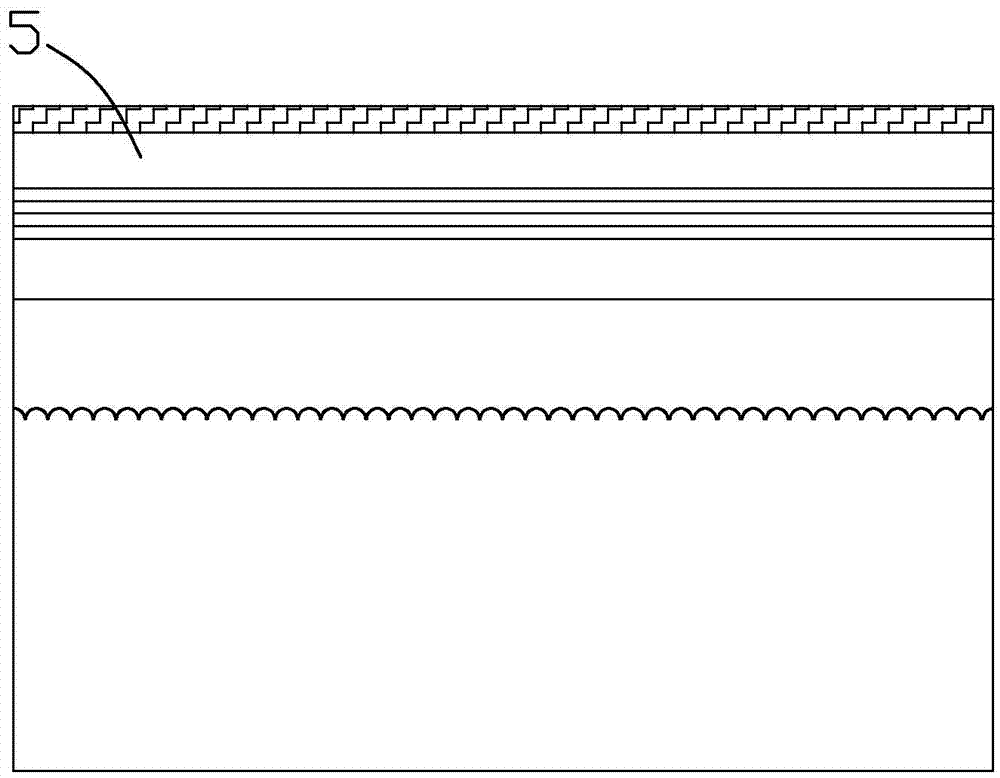

[0054] (3) P-type gallium nitride surface roughening

[0055] ...

Embodiment 2

[0070] A method for manufacturing a flip-chip high-voltage LED chip as described above includes the following steps:

[0071] (1) Treat the substrate

[0072] Thinning, grinding and CMP polishing the back of the epitaxial wafer substrate grown on GaN to reduce its thickness from 430 μm to 180 μm, surface flatness (TTV) ≤ 50 μm, warpage (BOW) ≤ 50 μm, average roughness Degree S a ≤0.2nm;

[0073] (2) Clean the epitaxial layer

[0074] Pickle the light gallium nitride epitaxial wafer on which the chip is made, and wash it with aqua regia (HCl: HNO 3 =3:1) Imaging and etching for 30 minutes, mainly cleaning and removing metal pollutants on the wafer surface; 2 SO 4 :H 2 o 2 = 1:4 wash at room temperature for 5 minutes, mainly to remove surface organic contamination; then use HF:H 2 O (DI, ultrapure water) = 1: 1 to remove the oxide layer on the wafer surface, and finally rinse and dry with deionized water;

[0075] (3) Surface roughening of P-type gallium nitride

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com