PS/Fe3O4/graphene composite aerogel and preparation method thereof

A graphene composite, aerogel technology, applied in separation methods, chemical instruments and methods, grease/oily substance/float removal devices, etc., can solve the problem of not reaching ultra-high oil absorption, high price, and small contact area and other problems, to achieve the effect of improving adsorption capacity, low price and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

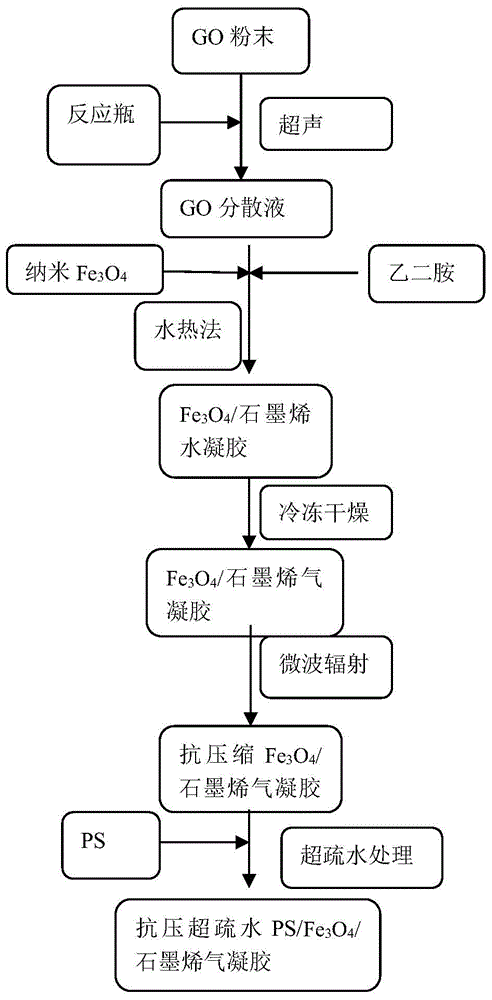

[0021] A PS / Fe 3 o 4 The preparation method of / graphene composite airgel comprises the following steps:

[0022] (1) According to the ratio of graphite oxide (GO): deionized water is 3g:1L, GO is added to deionized water, and the temperature is controlled at 20-40°C for 3-5h to obtain a uniform dispersion. Transfer the GO solution to a glass bottle, calculated by mass ratio, namely Fe 3 o 4 : Ethylenediamine: GO is the ratio of 1:10:15-1:2:3, Fe 3 o 4 Add ethylenediamine and ethylenediamine to the obtained GO dispersion, control the temperature at 20-40°C, conduct ultrasonication for 1-2min, seal it, and then heat it in a water bath at 90-98°C for 6-8h to obtain Fe 3 o 4 / graphene composite hydrogel.

[0023] (2) Freeze-dry the product after the water bath in step (1) at -75-(-50)°C for 5-7d to obtain a non-compressive composite airgel. Compression-resistant Fe 3 o 4 / Graphene composite airgel.

[0024] (3) Calculated according to the mass ratio, that is, acetone s...

Embodiment 1

[0029] Fe 3 o 4 The preparation method of / graphene composite airgel (concrete process such as figure 1 shown):

[0030] Add 15mg of graphite oxide (GO) into 5mL of deionized water, control the temperature at 20-40°C and perform ultrasonication for 4h to obtain a uniform dispersion. The GO solution was transferred to a glass bottle, and then 3 mg Fe 3 o 4 Add nanoparticles and 10mg ethylenediamine to the step GO dispersion, control the temperature at 20-40°C for 2 minutes, and seal it, then heat it in a water bath at 98°C for 6 hours to obtain Fe 3 o 4 / graphene composite hydrogel. will get Fe 3 o 4 / graphene composite hydrogel was freeze-dried at -75-(-50)℃ for 5 days to obtain a non-compression-resistant composite aerogel. Compression-resistant Fe3 o 4 / Graphene composite airgel.

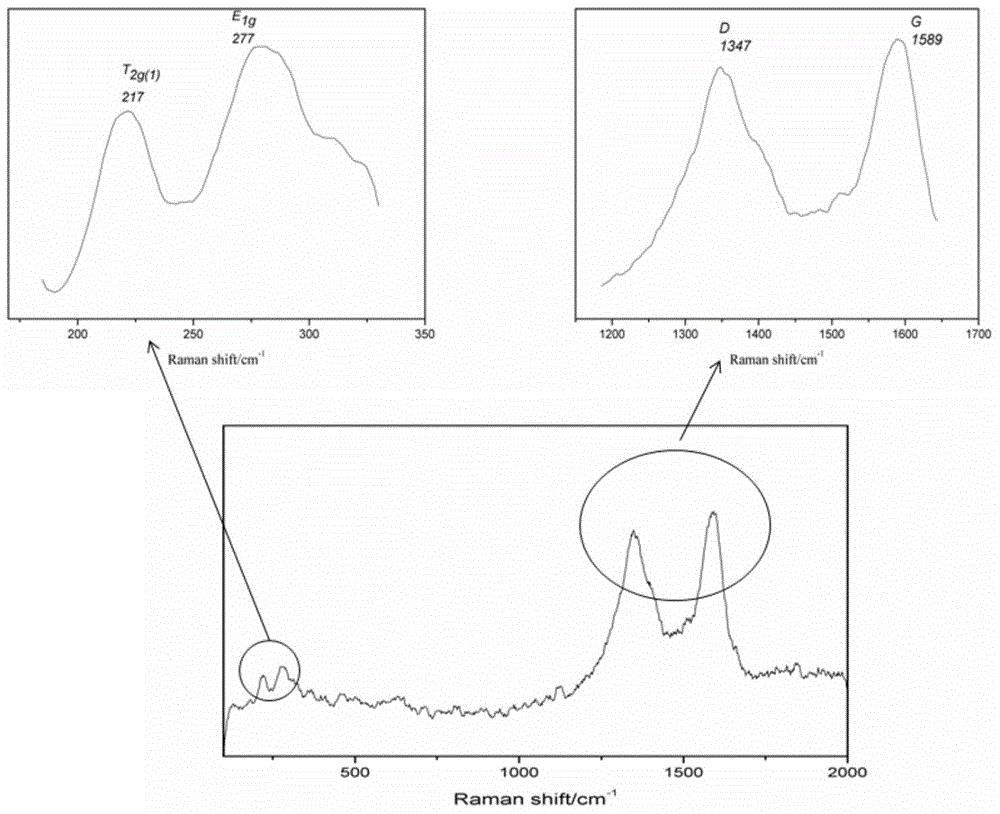

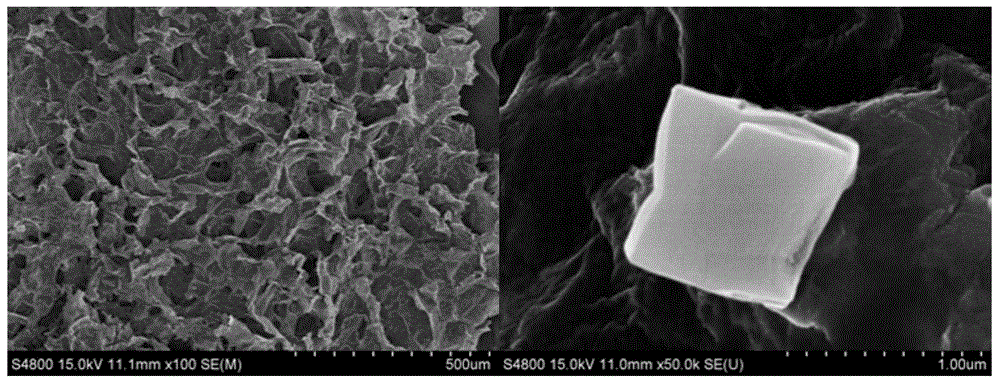

[0031] The Fe prepared in above-mentioned embodiment 1 3 o 4 / Graphene composite aerogels can be attracted by magnets, proving that composite aerogels are magnetic. The Fe prepared i...

Embodiment 2

[0035] PS / Fe 3 o 4 The preparation method of / graphene composite airgel (concrete process such as figure 1 shown):

[0036] 2g of polystyrene microspheres (PS) were mixed with 20mL of acetone solution, and the temperature was controlled at 20-40°C for 2h of sonication. Then the PS acetone mixed solution was added dropwise to the anti-compression Fe 3 o 4 / graphene composite airgel, and at 35°C, vacuum-dried for 1-2h, and finally obtained PS / Fe 3 o 4 / Graphene composite airgel.

[0037] The PS / Fe prepared in above-mentioned embodiment 2 3 o 4 / Graphene composite airgel, when dropping small droplets on the surface of the composite airgel, the small droplets stay on the surface of the composite airgel like dew on the lotus leaf, and in the case of inversion, the small liquid The droplet remains "sticky" to the surface of the composite airgel. This shows that the preparation scheme of the composite airgel of the present invention can prepare a "sticky" hydrophobic compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com