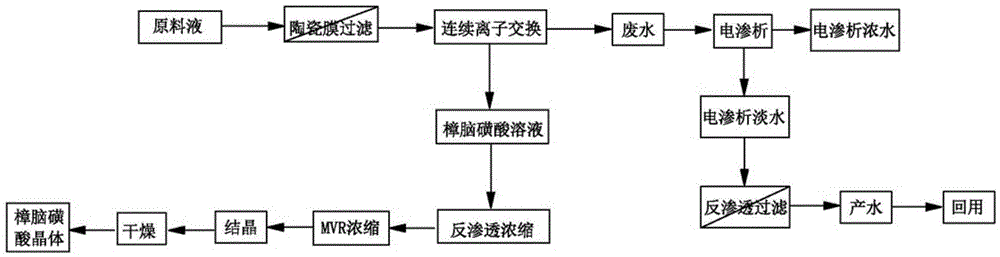

Clean production process for converting camphor ammonium sulfonate into camphorsulfonic acid

A technology of ammonium camphorsulfonate and camphorsulfonic acid, which is applied in the preparation of sulfonic acid, preparation of organic compounds, organic chemistry, etc., can solve the problems of long production cycle, low total yield, poor product purity, etc. Small size, simple process and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

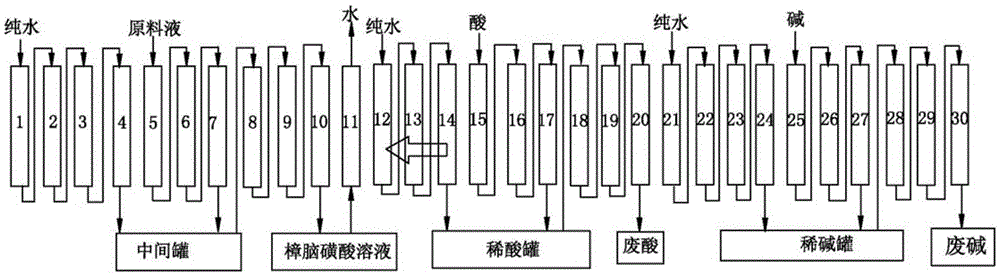

Method used

Image

Examples

Embodiment 1

[0039] Wherein: the raw material liquid in step 1 adopts 25% ammonium camphorsulfonate solution, adopts the ceramic membrane that aperture is 50nm; Hydrochloric acid and sodium hydroxide are 4% sodium hydroxide;

Embodiment 2

[0041] Wherein: the raw material solution in step 1 adopts 15% ammonium camphorsulfonate solution, adopts the ceramic membrane that aperture is 100nm; Hydrochloric acid and sodium hydroxide are 4% sodium hydroxide;

Embodiment 3

[0043] Wherein: the raw material liquid in the step 1 adopts 30% ammonium camphorsulfonate solution, adopts the ceramic membrane that aperture is 200nm; Hydrochloric acid and alkali are 4% sodium hydroxide.

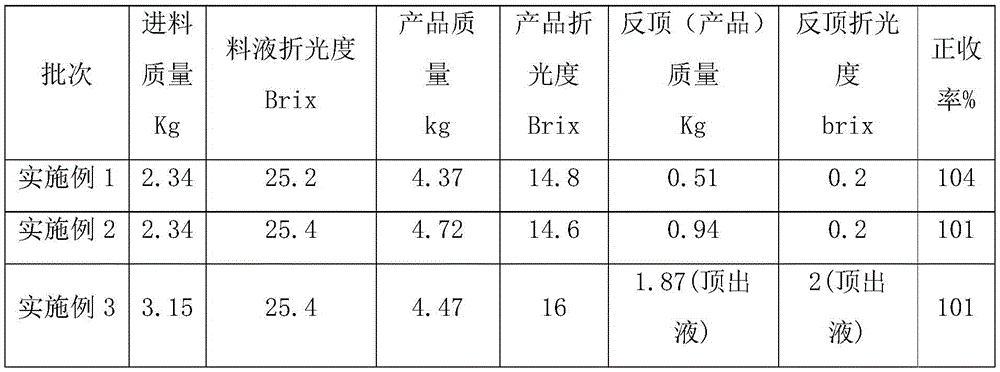

[0044] The result is as follows:

[0045]

[0046]It can be seen from the above table that the positive calculation yields of the three batches of experiments are all above 100%. Excluding the error in weighing, it can be seen that there is basically no loss in the product. At the same time, it can be seen from the color change of the resin on site The conversion is very thorough.

[0047] The camphorsulfonic acid solution obtained by continuous ion exchange is concentrated by reverse osmosis, concentrated by MVR, crystallized, centrifuged, and crystals are dried. After the camphorsulfonic acid crystals are tested, the purity of the camphorsulfonic acid crystals can reach more than 99.5%, reaching pharmaceutical grade camphor. Sulfonic acid levels.

[0048] In addit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap