Two-way stretch fabric and producing technology thereof

A technology of production process and function, applied in the field of textile printing and dyeing, can solve the problems of difficult control of the production process, complicated production process and high production cost, and achieve the effect of being suitable for wide-scale promotion and application, soft and comfortable to the touch, and maintaining aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

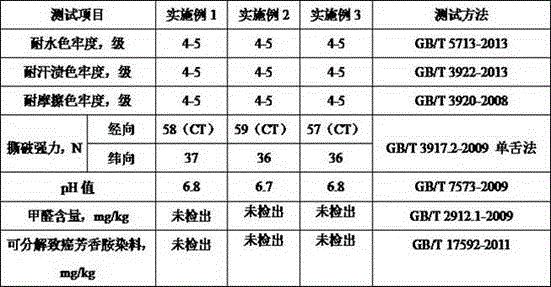

Examples

Embodiment 1

[0034] The manufacturing process of the fabric with four-sided elastic function comprises the following steps:

[0035] Step 1, distributing: use warp yarn nylon 70D+spandex 40D×weft yarn nylon 70D+spandex 40D gray cloth for distributing;

[0036] Step 2, cold stacking: the gray cloth obtained in step 1 is passed through a cold stacking machine for cold rolling foam solution, the temperature of the first chemical tank is 60°C, the temperature of the second chemical tank is 80°C, and the temperature of the third chemical tank is at a temperature of 80°C at a speed of 50m?min, and then roll the gray cloth on a shaft car and rotate it for 24 hours to obtain a cold-stacked gray cloth; among them, add The additives are: add liquid caustic soda (sodium hydroxide) 60g?L, penetrant (dioctyl sulfosuccinate sodium salt) 4g?L, degreasing agent (ethylene-methacrylate polymer) in sequence according to the water volume ) 5g?L, refining agent (fatty alcohol ether phosphate) 12g?L, mix and s...

Embodiment 2

[0047] The manufacturing process of the fabric with four-sided elastic function comprises the following steps:

[0048] Step 1, distributing: use warp yarn nylon 70D+spandex 40D×weft yarn nylon 70D+spandex 40D gray cloth for distributing;

[0049] Step 2, cold stacking: the gray cloth obtained in step 1 is passed through a cold stacking machine for cold-rolling foam solution, the temperature of the first chemical tank is 55°C, the temperature of the second chemical tank is 75°C, and the temperature of the third chemical tank is The temperature is 75°C and the speed is 50m?min, and then the gray cloth is rolled on the axle car and rotated for 25 hours to obtain the cold-stacked gray cloth; among them, the first chemical tank, the second chemical tank and the third chemical tank The additives added in the solution are: according to the water volume, 55g?L of liquid caustic soda (sodium hydroxide), 3g?L of penetrating agent (sodium dioctyl sulfosuccinate), 3g?L of degreasing agen...

Embodiment 3

[0060] The manufacturing process of the fabric with four-sided elastic function comprises the following steps:

[0061] Step 1, distributing: use warp yarn nylon 70D+spandex 40D×weft yarn nylon 70D+spandex 40D gray cloth for distributing;

[0062] Step 2, cold stacking: the gray cloth obtained in step 1 is passed through a cold stacking machine for cold-rolling foam solution. The temperature of the first chemical tank is 55°C, the temperature of the second chemical tank is 85°C, and the temperature of the third chemical tank is at a temperature of 85°C at a speed of 50m?min, and then roll the gray cloth on a shaft car for 23 hours to obtain a cold-stacked gray cloth; among them, add The additives are: add liquid caustic soda (sodium hydroxide) 65g?L, penetrant (dioctyl sulfosuccinate sodium salt) 5g?L, degreasing agent (ethylene-methacrylate polymer) in sequence according to the water volume ) 7g?L, refining agent (fatty alcohol ether phosphate) 14g?L, mix and stir evenly;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com