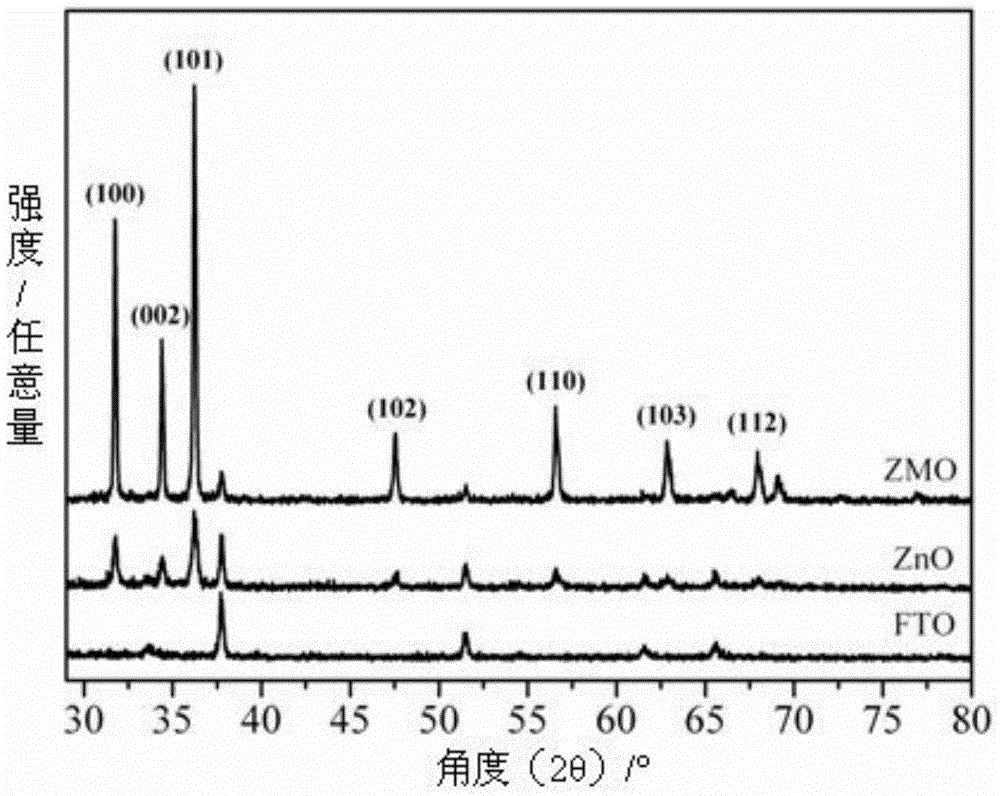

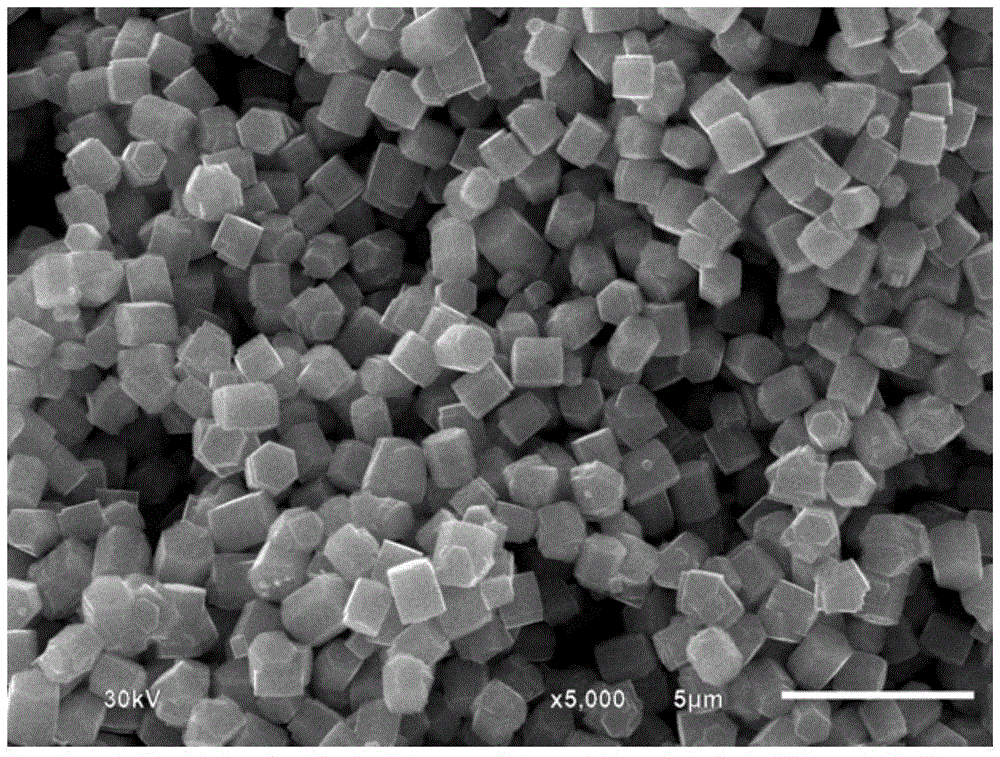

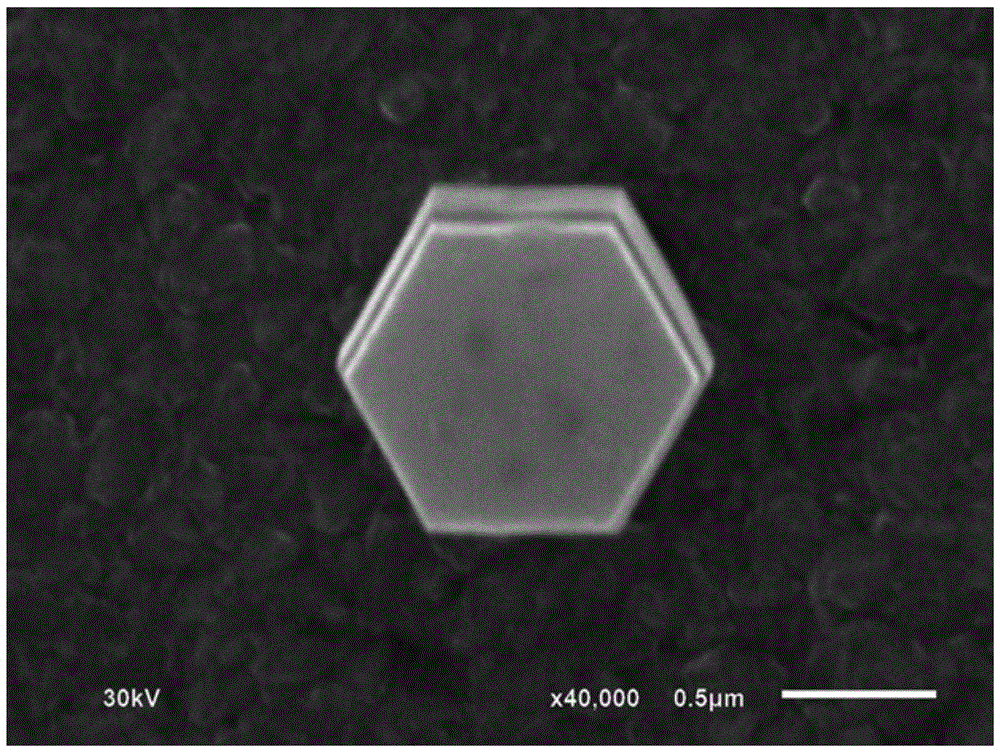

Preparation method for regular-hexagonal-prism-shaped magnesium-doped zinc oxide film

A zinc oxide thin film and regular hexagonal prism technology, which is applied in the field of semiconductor material preparation, can solve problems such as no research reports, and achieve the effects of uniform morphology distribution, controllable morphology and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation steps of a regular hexagonal prism-shaped magnesium-doped zinc oxide film are as follows:

[0041] (1) Prepare a mixed solution of ethylene glycol and ice water with a volume ratio of 1:5 and stir evenly;

[0042] (2) Add zinc acetate again, control its concentration to be 0.15mol / L, stir to make it fully dissolve;

[0043] (3) Add triethanolamine again, control its concentration to be 0.77mol / L, stir to make it fully dissolve;

[0044] (4) Add magnesium acetate again, control its concentration to be 0.15mol / L and stir to make it fully dissolve;

[0045] (5) add ammoniacal liquor again, control its concentration to be 0.28mol / L, stir evenly, obtain uniform reaction solution system;

[0046] (6) The FTO glass was ultrasonically cleaned with acetone, ethanol and distilled water for 30 minutes, and then washed with N 2 blow dry;

[0047] (7) Put the cleaned FTO glass vertically into a polytetrafluoroethylene-lined reactor;

[0048] (8) Transfer the rea...

Embodiment 2

[0059] The preparation steps of a regular hexagonal prism-shaped magnesium-doped zinc oxide film are as follows:

[0060] (1) Prepare a mixed solution of ethylene glycol and ice water with a volume ratio of 1:10 and stir evenly;

[0061] (2) Add zinc acetate again, control its concentration to be 0.077mol / L, stir to make it fully dissolve;

[0062] (3) Add triethanolamine again, control its concentration to be 0.77mol / L, stir to make it fully dissolve;

[0063] (4) Add magnesium acetate again, control its concentration to be 0.23mol / L, stir to make it fully dissolve;

[0064] (5) add ammoniacal liquor again, control its concentration to be 0.28mol / L, stir evenly, obtain uniform reaction solution system;

[0065] (6) The FTO glass was ultrasonically cleaned with acetone, ethanol and distilled water for 10 minutes, and then washed with N 2 blow dry;

[0066] (7) Put the cleaned FTO glass vertically into a polytetrafluoroethylene-lined reactor;

[0067] (8) Transfer the reac...

Embodiment 3

[0071] The preparation steps of a regular hexagonal prism-shaped magnesium-doped zinc oxide film are as follows:

[0072] (1) Prepare a mixed solution of ethylene glycol and ice water with a volume ratio of 1:10 and stir evenly;

[0073] (2) Add zinc acetate again, control its concentration to be 0.23mol / L, stir to make it fully dissolve;

[0074] (3) Add triethanolamine again, control its concentration to be 0.77mol / L, stir to make it fully dissolve;

[0075] (4) Add magnesium acetate again, control its concentration to be 0.077mol / L, stir to make it fully dissolve;

[0076] (5) add ammoniacal liquor again, control its concentration to be 0.28mol / L, stir evenly, obtain uniform reaction solution system;

[0077] (6) The FTO glass was ultrasonically cleaned with acetone, ammonia water and deionized water for 10 minutes respectively, and then washed with N 2 blow dry;

[0078] (7) Put the cleaned FTO glass vertically into a polytetrafluoroethylene-lined reactor;

[0079] (8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com