Method for preparing membrane electrode from chitin nano fiber/carbon nanotube composite

A carbon nanotube composite and nanofiber technology, which is used in hybrid capacitor electrodes and hybrid/electric double layer capacitor manufacturing, etc. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

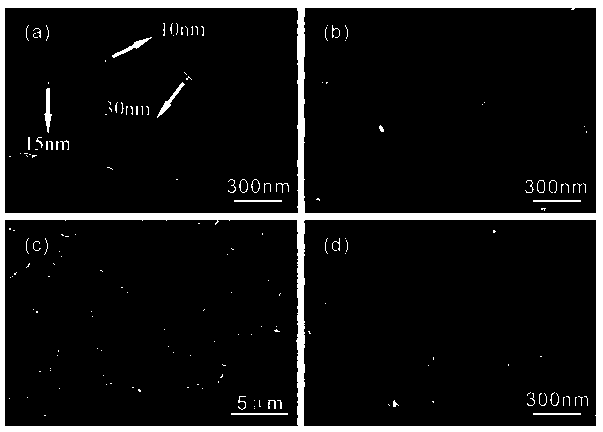

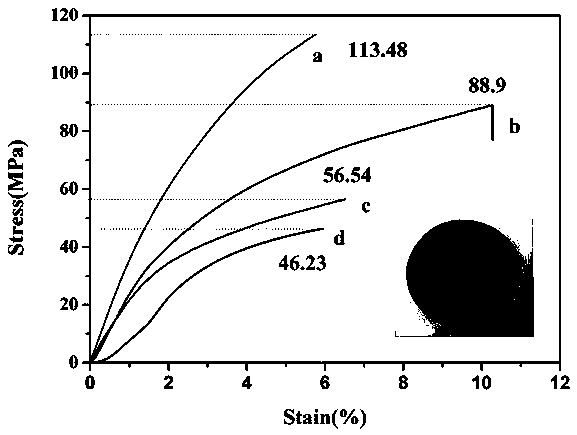

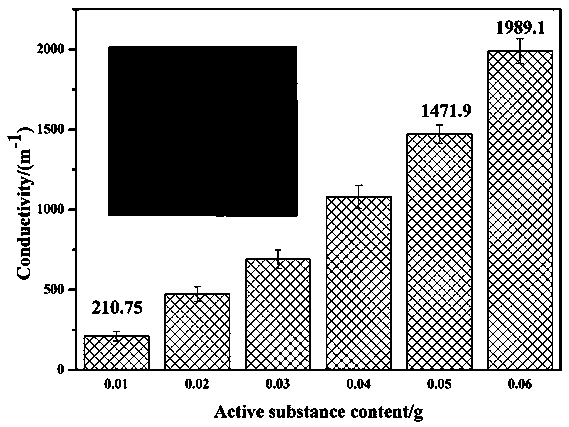

Image

Examples

Embodiment 1

[0034] The preparation method of extracting chitin nanofibers from shrimp shells includes the steps (1) selecting edible shrimp shells, washing and drying them, using an electronic balance to accurately weigh 10g and putting them into a beaker, adding 600ml deionized water, and using 7wt% Hydrochloric acid (HCl) was left at room temperature for 24 hours to remove the calcium carbonate in the shrimp shell, and then rinsed with a large amount of deionized water until neutral;

[0035] Step (2) Soak the shrimp shells in a 5% potassium hydroxide (KOH) solution, place them in a water bath at 95°C for 6 hours, remove the protein in the shrimp shells, and then rinse them with a large amount of deionized water until medium. properties; this process was repeated four times to ensure adequate protein removal;

[0036] Step (3) Place the treated shrimp shells in 75% ethanol solution for 24 hours, seal and let stand to remove the pigment, and then rinse until neutral to obtain purified ch...

Embodiment 2

[0048] A preparation method for extracting chitin nanofibers from crab shells, including

[0049] Step (1) Select the crab shells that have been eaten, wash and dry them, weigh 10g with an electronic balance, put them into a beaker, add 600ml of deionized water, and let them stand for 24 hours with 6wt% hydrochloric acid (HCl) at room temperature to remove the crab shells. Calcium carbonate in the shell, then washed to neutrality with copious amounts of deionized water;

[0050] Step (2) Soak the crab shells in a 6% potassium hydroxide (KOH) solution, place them in a water bath at 100°C for 6 hours, remove the protein in the crab shells, and then rinse them with a large amount of deionized water until medium. properties; this process was repeated four times to ensure adequate protein removal;

[0051] Step (3) Place the treated crab shells in 95% ethanol solution for 48 hours, seal and let stand to remove the pigment, and then rinse until neutral to obtain purified chitin;

...

Embodiment 3

[0062] Preparation method for extracting chitin nanofibers from commercially purchased chitin powder, comprising

[0063] Step (1) Sieve 40-60 mesh chitin powder, after drying, use an electronic balance to accurately weigh 10g, put it into a beaker, add 600ml of deionized water, and let it stand for 24 hours with 5wt% hydrochloric acid (HCl) at room temperature. Remove the calcium carbonate in chitin, then rinse with a large amount of deionized water until neutral;

[0064] Step (2) Soak chitin in a 7% potassium hydroxide (KOH) solution, place it in a water bath at 90°C for 6 hours, remove the protein in the chitin, and then rinse it with a large amount of deionized water until the medium sex;

[0065] Step (3) Use 5wt% hydrochloric acid to stand at room temperature for 12 hours, and then rinse with a large amount of deionized water until neutral;

[0066] Step (4) Soak chitin in a 5% potassium hydroxide (KOH) solution for 24 hours at room temperature. This process is repeat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com