Dendritic tetrameric quaternary ammonium salt surfactant preparation method

A surfactant and polyquaternary ammonium salt technology, which is applied in the preparation of polyamide-amine dendritic quaternary ammonium salt surfactants, and the field of preparation of quaternary ammonium salt surfactants, can solve the problem of single morphological structure and single reaction core, etc. problems, to achieve the effect of easy availability of raw materials, high surface activity, and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

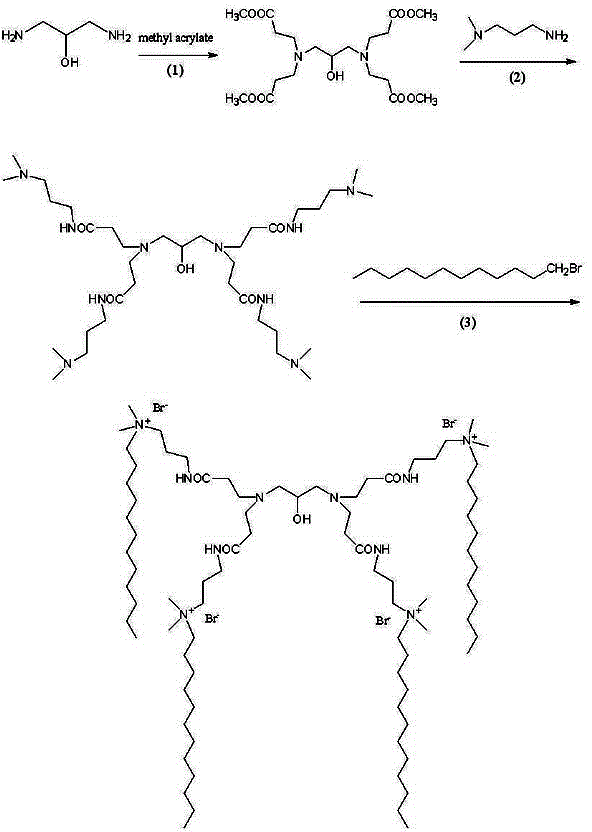

[0029] Embodiment 1, the preparation of a kind of quaternized polyamide-amine dendritic surfactant

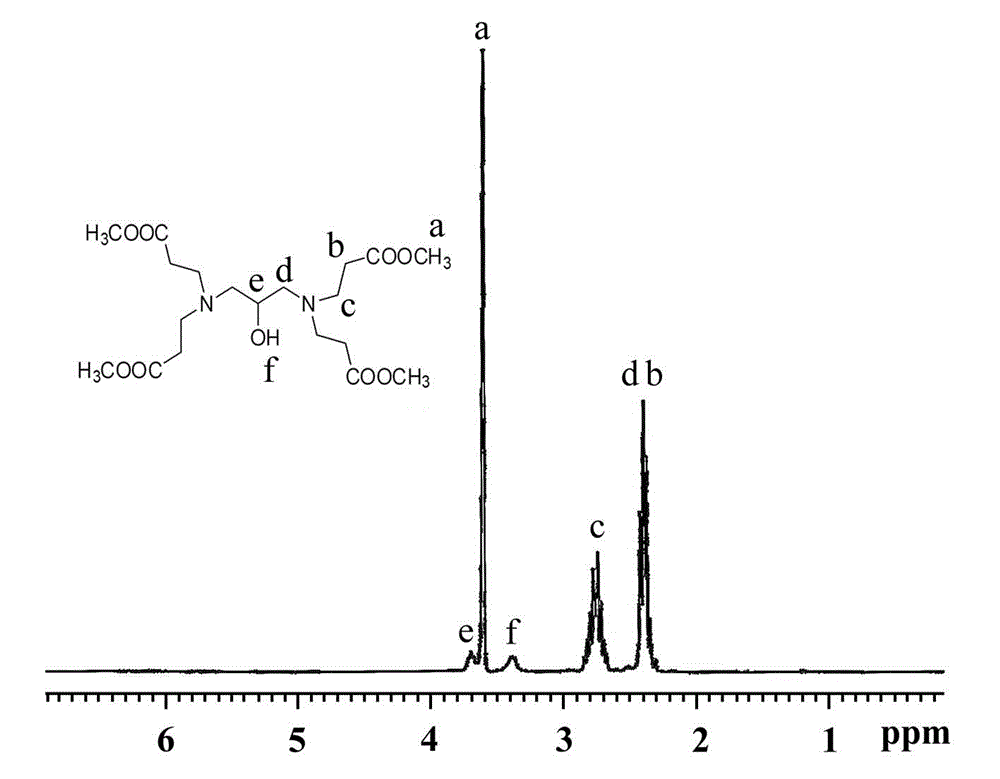

[0030] (1) Preparation of compound (I)

[0031] Place a 50mL three-necked flask in an ice-water bath, first pass nitrogen gas for 3~5min, weigh 0.9g (10mmol) of 2-hydroxy-1,3-propanediamine, dissolve it in 10ml of methanol, add it to the three-necked flask, and continue stirring for 20min , then measure 17.2g (200mmol) methyl acrylate, drop it into the flask at a rate of drop / 3s, after the dropwise addition, wait for the temperature to rise to room temperature naturally, then heat up to 30°C, N 2 Under protection, the stirring reaction was continued for 36h. After the reaction, add methanol repeatedly for vacuum rotary evaporation to remove excess methyl acrylate, and finally remove the solvent methanol by rotary evaporation. The vacuum rotary evaporation temperature is controlled at 30~35°C. During vacuum rotary evaporation, the pressure should be increased a little to preven...

Embodiment 2

[0036] Embodiment 2, the preparation of a kind of quaternized polyamide-amine dendritic surfactant

[0037] (1) Preparation of compound (I)

[0038] As described in Example 1, the difference is that the quality of methyl acrylate is changed to 5.16g (60mmol), the quality of the obtained compound (I) is 4.23g, and the yield is 97.74%. The analysis of the hydrogen spectrum shows that the obtained non-target product , not connected with four chains, suspected to be a mixture of three chains and two chains.

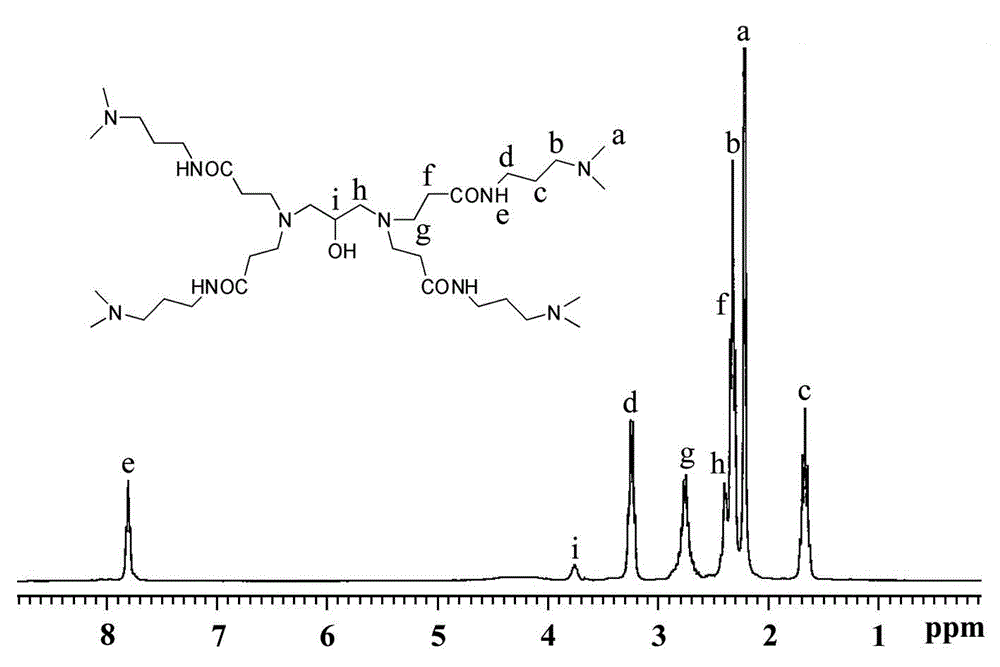

[0039] (2) Preparation of Compound (II)

[0040]As described in Example 1, the difference is that the mass of N,N-dimethyl-1,3-propanediamine is changed to 4.22g (41.4mmol), and after reaction 5, the compound (I) is still not completely reacted .

[0041] (3) Preparation of Compound (Ⅲ)

[0042] As described in Example 1, the difference is that the mass of compound (II) is changed to 0.77g (1.08mmol), the volume dissolved in the solvent is 6mL, and the mass of bromododeca...

Embodiment 3

[0043] Embodiment 3, the preparation of a kind of quaternized polyamide-amine dendritic surfactant

[0044] (1) As described in Example 1, the difference is that the mass of 2-hydroxy-1,3-propylenediamine is changed to 0.18g (2mmol), and the mass of methyl acrylate is changed to 2.06g (24mmol), The mass of the obtained compound (I) was 0.41 g, and the yield was 96%. According to the analysis of the hydrogen spectrum, as the proportion of methyl acrylate increased, the product was suspected to be part of the target product and part of the three-chain product.

[0045] (2) As described in Example 1, the difference is that the reaction temperature is increased to 40°C, and the reaction time is 4-5 days, but there are miscellaneous peaks in the hydrogen spectrum, and the product is impure.

[0046] (3) As described in Example 1, the difference is that the mass of compound (II) is changed to 0.79g (1.1mmol), the volume dissolved in the solvent is 6mL, and the mass of bromododecane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com