Method for preparing copper oxide/cuprous oxide-based antibacterial material through in situ polymerization

A cuprous oxide, in-situ polymerization technology, applied in rayon manufacturing, fiber chemical characteristics, single-component polyester rayon, etc., can solve the problem of large amount of addition, difficult continuous production, uneven distribution of antibacterial components and other problems, to achieve the effect of large amount of addition, lasting effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

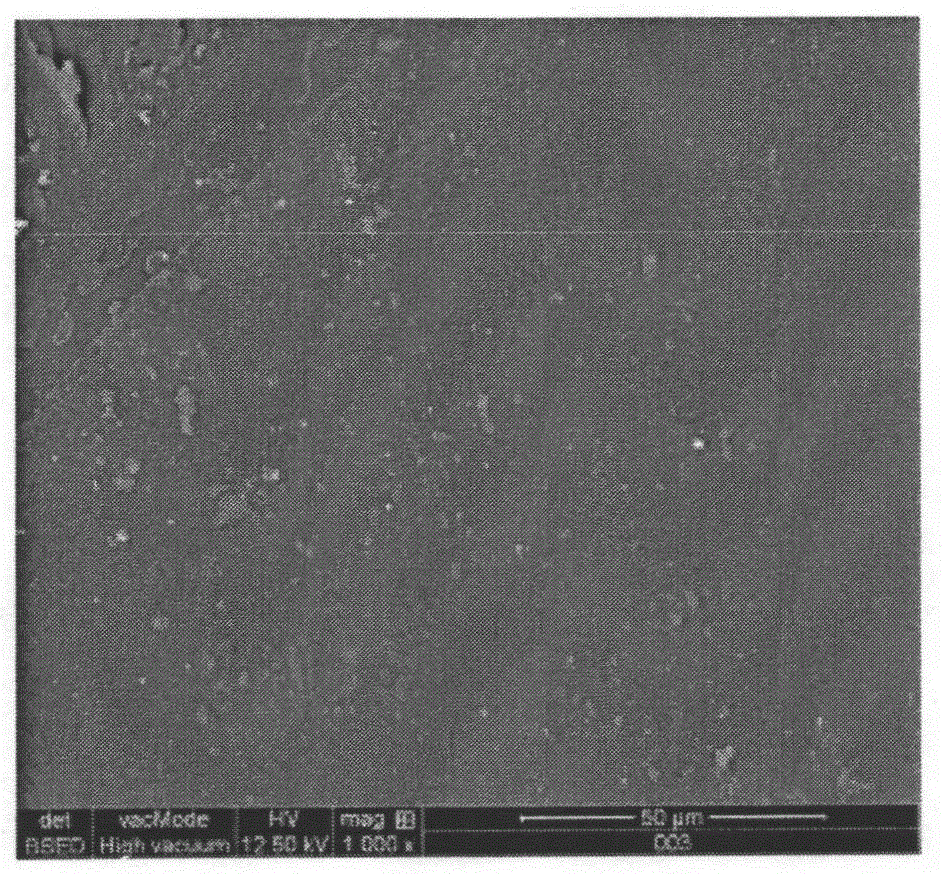

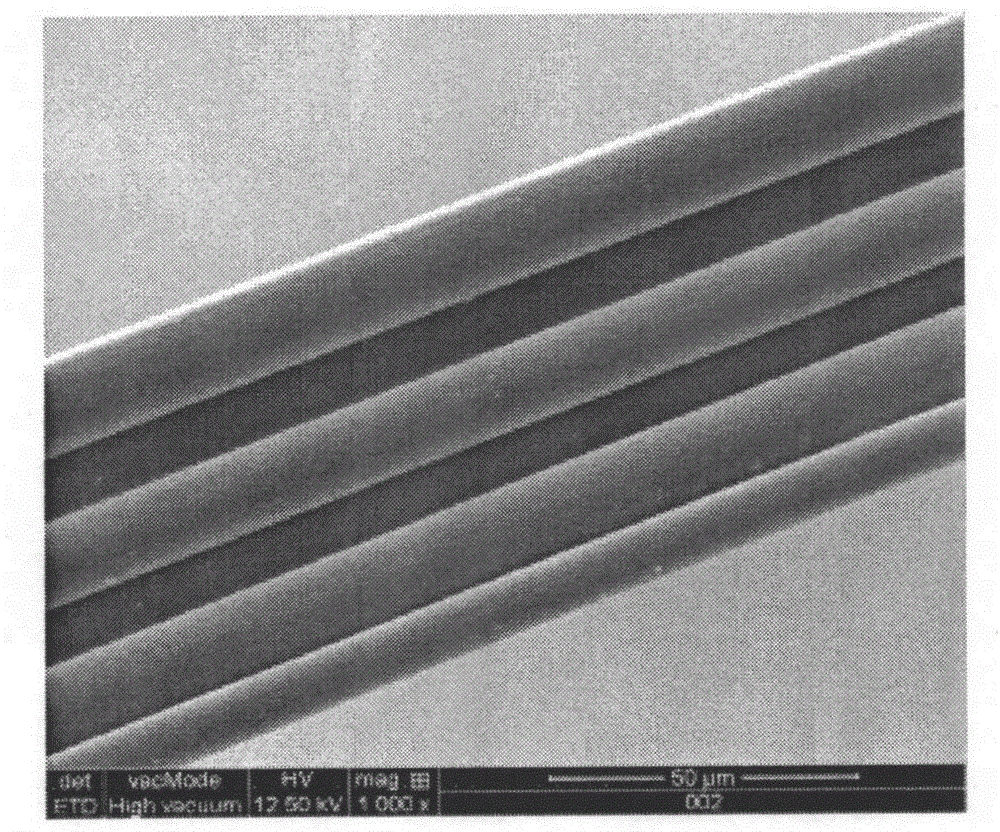

Image

Examples

Embodiment 1

[0026] A method for preparing an antibacterial material based on copper oxide / cuprous oxide by in-situ polymerization, the specific steps are:

[0027] The first step: use copper oxide and cuprous oxide with a mass ratio of 50:50 to form an antibacterial powder, add 22.4g of antibacterial powder and 12.5g of diphenylmethane diisocyanate to 100ml of DMF solvent, and react at 80°C for 2h , after filtering and drying, the copper oxide / cuprous oxide composite antibacterial powder is obtained.

[0028] The second step: take the above-mentioned copper oxide / cuprous oxide composite antibacterial powder mass fraction as 5%, reaction monomer (terephthalic acid and ethylene glycol, molar ratio is 1: 1.2), stabilizer trimethyl phosphate (mass fraction is 50ppm) and catalyst ethylene glycol antimony (mass fraction is 300ppm), total mass fraction is 100%, joins in the polymerization reactor by in-situ polymerization (reaction process is: 230 ℃, 300kpa reaction 2h; 275 ℃ , 150pa reaction f...

Embodiment 2

[0031] A method for preparing an antibacterial material based on copper oxide / cuprous oxide by in-situ polymerization, the specific steps are:

[0032] The first step: use copper oxide and cuprous oxide with a mass ratio of 10:90 to form antibacterial powder, add 22.4g antibacterial powder and 12.5g diphenylmethane diisocyanate to 100ml after water removal treatment (put DMF into The dried molecular sieves were placed in a DMF solvent for 48 h), reacted at 80° C. for 2 h, filtered and dried to obtain a copper oxide / cuprous oxide composite antibacterial powder.

[0033] Second step: the above-mentioned copper oxide / cuprous oxide composite antibacterial powder mass fraction is 2%, reaction monomer (terephthalic acid and propylene glycol, molar ratio is 1: 1.3), stabilizer mass fraction is 30ppm (phosphoric acid Dimethyl ester) and catalyst mass fraction are 300ppm (ethylene glycol antimony), and total mass fraction is 100%, join in the polymerization reactor by in-situ polymeriz...

Embodiment 3

[0035] A method for preparing an antibacterial material based on copper oxide / cuprous oxide by in-situ polymerization, the specific steps are:

[0036]The first step: use copper oxide and cuprous oxide with a mass ratio of 90:10 to form an antibacterial powder, add 22.4g of antibacterial powder and 6g of diphenylmethane diisocyanate to 100ml of chloroform solvent, at 60°C React for 4 hours, filter and dry to obtain copper oxide / cuprous oxide composite antibacterial powder.

[0037] The second step: the mass fraction of the above-mentioned cupric oxide / cuprous oxide composite antibacterial powder is 3%, the mass fraction of the reaction monomer (caprolactam) is 97%, and the total content is 100%. Polymerization (reaction process is 220 ~ 240 ° C, 0.5Mpa ring opening for 3 hours, polycondensation reaction at 280 ° C for 3 hours) to prepare antibacterial resin based on cupric oxide / cuprous oxide, after drying, control the moisture content at 50 ~ 100ppm (mass content ), the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com