Preparation method of modified polyaniline catalyst for synthesizing 5-hydroxymethyl furfural

A technology of hydroxymethyl furfural and polyaniline, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low HMF selectivity and catalyst reuse rate Low catalyst active sites are easily deactivated, etc., to achieve the effects of high catalyst activity, low cost, and easy separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

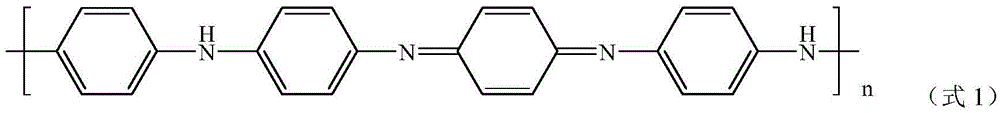

Image

Examples

Embodiment 1

[0012] 156mmol of sulfuric acid and 44mmol of freshly distilled aniline monomer were prepared into 200mL aqueous solution. The molar ratio of ammonium persulfate to aniline monomer is 1.4:1. Slowly drop solution B into solution A at a rate of 4 mL / min, and control the solution temperature at 5°C; after the addition is complete, continue stirring at 5°C for 40 minutes; then add 1L of distilled water to dilute and quench the reaction; filter out the solid, Wash with distilled water until the pH of the filtrate is neutral, then wash off the aniline oligomers that may be formed with methanol and ether, and dry the solid at 100°C for 12 hours in vacuum, then grind it into powder. Take 0.2 g of polyaniline salt powder, add 4 mL of 40% formaldehyde aqueous solution by mass percentage, and react at 140° C. for 4 hours. After the reaction, it was naturally cooled to room temperature, filtered, washed with water, sucked dry, and vacuum-dried at 100°C for 12 hours to obtain a modified p...

Embodiment 2-5

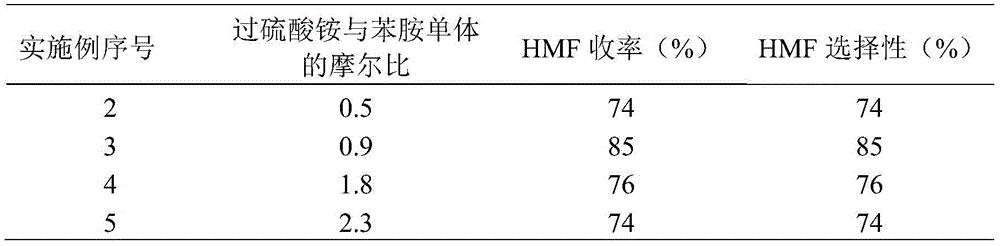

[0015] Prepare the catalyst according to the method of Example 1, change the molar ratio of ammonium persulfate to aniline monomer to 0.5, 0.9, 1.8 and 2.3, and use the prepared catalyst for the dehydration reaction of fructose. The reaction results are listed in Table 1.

[0016] Table 1.

[0017]

Embodiment 6-11

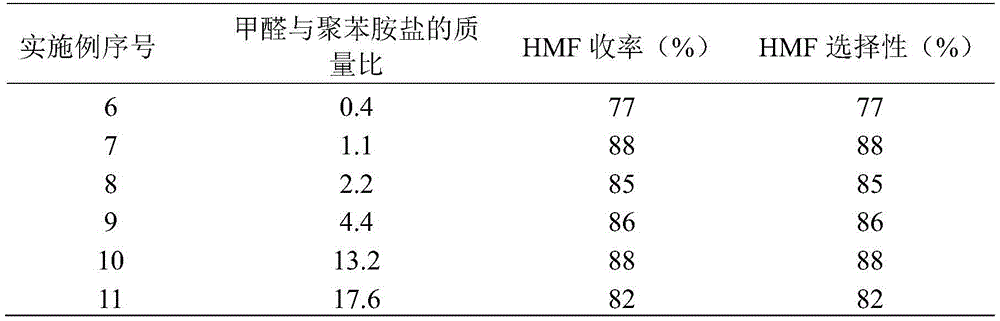

[0019] Prepare the catalyst according to the method of Example 1, change the mass ratio of formaldehyde and polyaniline salt to 0.4, 1.1, 2.2, 4.4, 13.2 and 17.6, and use the prepared catalyst for the dehydration reaction of fructose. The reaction results are listed in Table 2 .

[0020] Table 2.

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com