Cold-resistant and light-resistant NBR sole material and preparation method thereof

A shoe sole material and light-resistant technology, applied in the field of shoe sole materials, can solve problems such as cold resistance, poor light aging resistance, service life impact, and performance decline, and achieve the effects of improving light aging resistance, improving cold resistance, and reducing photodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

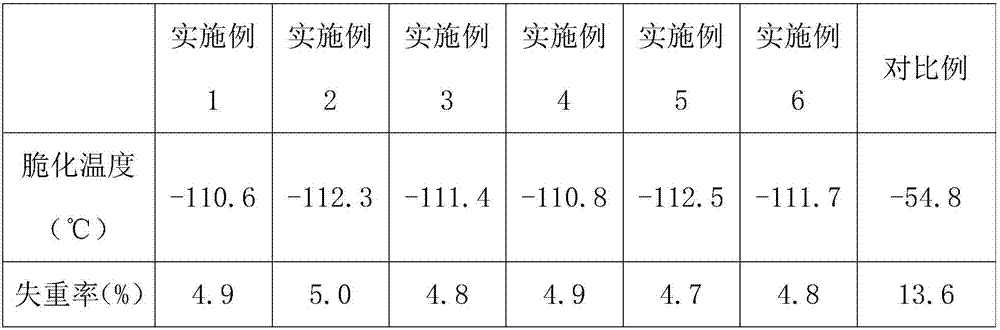

Examples

Embodiment 1

[0026] A cold-resistant and light-resistant NBR shoe sole material, made of the following components by weight: 100 parts of NBR, 5 parts of DOP, 14 parts of calcium carbonate, 3.6 parts of calcium-zinc composite stabilizer, 3.4 parts of carbon black, 2.5 parts of anti-aging agent RD 1.8 parts of sulfur, 1.6 parts of accelerator DZ, 5 parts of compatibilizer SEBS, 7.5 parts of modified nano tin oxide, 10 parts of PPO / PS, 1.5 parts of stearic acid, 4.8 parts of zinc oxide powder.

[0027] The steps of its preparation method are as follows:

[0028] (1) Add nano-tin oxide powder into deionized water, and ultrasonically disperse for 12 minutes to obtain a slurry with a mass fraction of 15%. After adding PEG20000, continue ultrasonically dispersing for 15 minutes, move to a reflux container at 80°C for 3 hours, and cool After reaching room temperature, the material is discharged, dried to constant weight after filtration, and modified nano-tin oxide is obtained after grinding;

...

Embodiment 2

[0032] A cold-resistant and light-resistant NBR shoe sole material, made of the following components in parts by weight: 100 parts of NBR, 7 parts of DOP, 12 parts of calcium carbonate, 3.2 parts of calcium-zinc composite stabilizer, 4 parts of carbon black, 2.4 parts of anti-aging agent RD 1.2 parts of sulfur, 1.5 parts of accelerator DZ, 6 parts of compatibilizer SEBS, 8.5 parts of modified nano tin oxide, 9 parts of PPO / PS, 1.2 parts of stearic acid, 5 parts of zinc oxide powder.

[0033] The steps of its preparation method are as follows:

[0034] (1) Add nano-tin oxide powder into deionized water, and ultrasonically disperse for 12 minutes to obtain a slurry with a mass fraction of 15%. After adding PEG20000, continue ultrasonically dispersing for 15 minutes, move to a reflux container at 80°C for 3 hours, and cool After reaching room temperature, the material is discharged, dried to constant weight after filtration, and modified nano-tin oxide is obtained after grinding;...

Embodiment 3

[0038] A cold-resistant and light-resistant NBR shoe sole material, made of the following components in parts by weight: 100 parts of NBR, 6.5 parts of DOP, 11 parts of kaolin, 4 parts of calcium-zinc composite stabilizer, 3 parts of carbon black, and 1.5 parts of anti-aging agent RD , 1.4 parts of sulfur, 1.4 parts of accelerator DZ, 5.5 parts of compatibilizer SEBS, 8 parts of modified nano-tin oxide, 11 parts of PPO / PS, 1 part of stearic acid, 4.2 parts of zinc oxide powder.

[0039] The steps of its preparation method are as follows:

[0040] (1) Add nano-tin oxide powder into deionized water, and ultrasonically disperse for 12 minutes to obtain a slurry with a mass fraction of 15%. After adding PEG20000, continue ultrasonically dispersing for 15 minutes, move to a reflux container at 80°C for 3 hours, and cool After reaching room temperature, the material is discharged, dried to constant weight after filtration, and modified nano-tin oxide is obtained after grinding;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com