Preparation method of garden soil conditioner

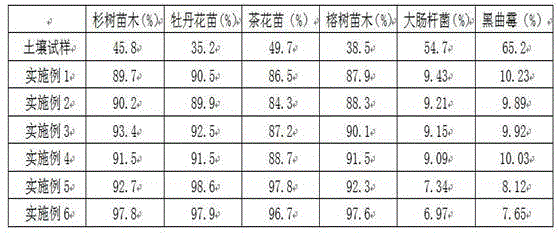

A soil improver and garden technology, applied in the field of preparation of garden soil improver, can solve the problems of lack of scientific guidance, soil compaction or reduced fertility, etc., achieve good antibacterial and mildew resistance, and provide the effect of survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of garden soil conditioner, comprising the following steps:

[0020] Step 1, in parts by weight, take 100 parts of dry straw, crush it, add 8 parts of chitosan powder, 5 parts of humic acid and 150 parts of gelatin solution, mix, heat up to 60 ° C for 4 hours, and then add tetrabutyl titanate 3 parts of ester, 7 parts of sodium alginate, 4 parts of calcium nitrate tetrahydrate, heat up to 90°C, keep warm for 3h, cool down to 10°C, filter to obtain a solid;

[0021] Step 2, in parts by weight, add 5 parts of calcium-based bentonite, 3 parts of tannic acid, 4 parts of lignin, 4 parts of polyacrylamide, 3 parts of vinyl acetate, 1 part of soybean lecithin, and 4 parts of p-toluenesulfonic acid Add to 10 parts of water, stir for 0.5h, then add 3 parts of polyaspartic acid, 2 parts of n-butyl triamine thiophosphate and 4 parts of Bracken, and mix to obtain mixture I;

[0022] Step 3, in parts by weight, add potassium hydroxide solution to the mixture I ...

Embodiment 2

[0027] A preparation method of garden soil conditioner, comprising the following steps:

[0028] Step 1, in parts by weight, take 108 parts of dry straw, crush it, add 10 parts of chitosan powder, 6 parts of humic acid and 170 parts of gelatin solution, mix, heat up to 65 ° C for 3 hours, and then add tetrabutyl titanate 8 parts of ester, 12 parts of sodium alginate, 7 parts of calcium nitrate tetrahydrate, heat up to 100°C, keep warm for 2h, cool down to 12°C, filter to obtain a solid;

[0029] Step 2, in parts by weight, add 8 parts of calcium-based bentonite, 7 parts of tannic acid, 12 parts of lignin, 8 parts of polyacrylamide, 6 parts of vinyl acetate, 2 parts of soybean lecithin, and 8 parts of p-toluenesulfonic acid Add 17 parts of water, stir for 1 hour, then add 6 parts of polyaspartic acid, 6 parts of n-butylthiophosphoric acid triamine and 7 parts of Bracken, and mix to obtain mixture I;

[0030] Step 3, in parts by weight, add potassium hydroxide solution to the m...

Embodiment 3

[0035] A preparation method of garden soil conditioner, comprising the following steps:

[0036] Step 1, in parts by weight, take 110 parts of dry straw, pulverize, add 14 parts of chitosan powder, 8 parts of humic acid and 170 parts of gelatin solution, mix, heat up to 70 ° C for 2 hours, and then add tetrabutyl titanate 8 parts of ester, 15 parts of sodium alginate, 8 parts of calcium nitrate tetrahydrate, heat up to 105°C, keep warm for 1h, cool down to 15°C, filter to obtain a solid;

[0037] Step 2, in parts by weight, add 8 parts of calcium-based bentonite, 8 parts of tannic acid, 11 parts of lignin, 9 parts of polyacrylamide, 5 parts of vinyl acetate, 2 parts of soybean lecithin, and 7 parts of p-toluenesulfonic acid into 17 parts of water, stirred for 1 hour, then added 7 parts of polyaspartic acid, 5 parts of n-butylthiophosphoric acid triamine and 7 parts of Bracken, and mixed to obtain mixture I;

[0038] Step 3, in parts by weight, add potassium hydroxide solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com