Molecular sieve catalyst for preparation of aromatic hydrocarbon through methanol conversion, and preparation method and application of catalyst

A methanol conversion and molecular sieve technology, which is applied to molecular sieve catalysts, including molecular sieve catalysts, carbon compound catalysts, etc., can solve the problem of low yield of xylene mixture, achieve optimized product distribution, high yield of aromatics and BTX, and improve economic operation horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

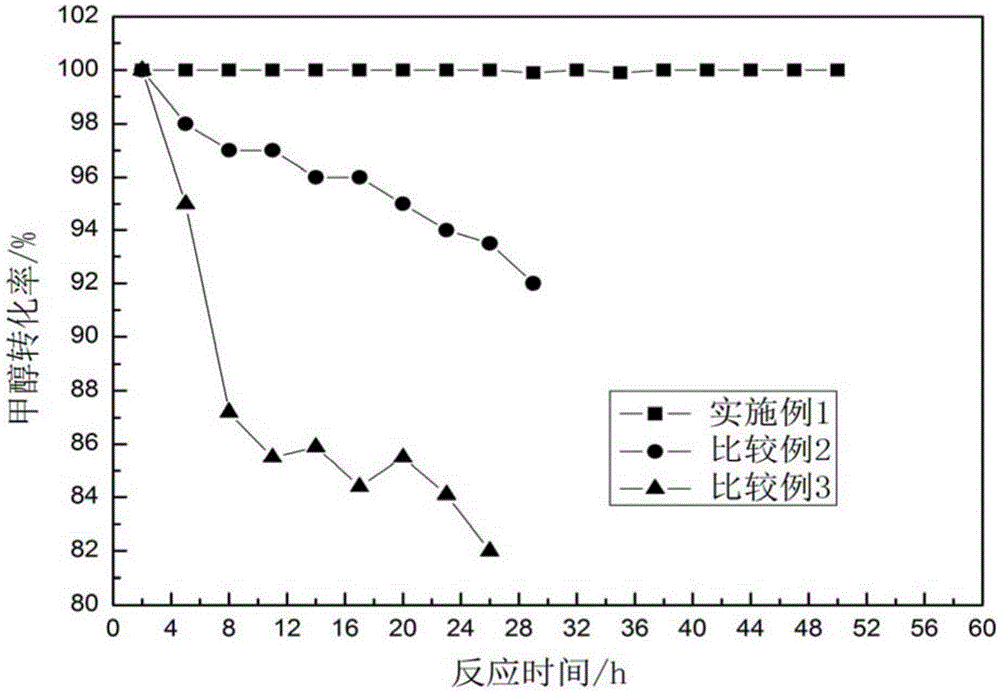

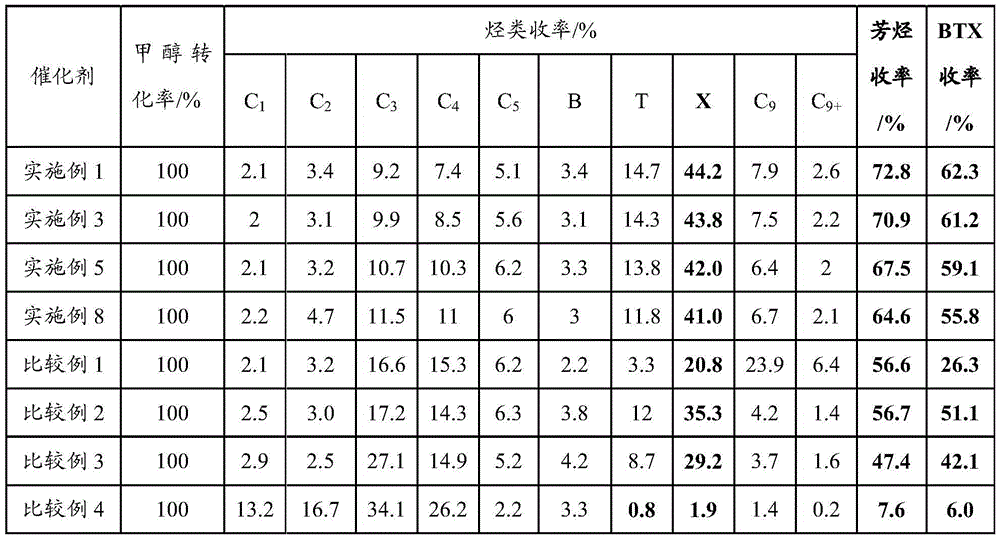

Examples

Embodiment 1

[0056] This example is used to illustrate the molecular sieve catalyst for methanol conversion to aromatics and its preparation method. Specifically, the preparation method of molecular sieve catalyst comprises the following steps:

[0057] (1) Modification of hydrogen ZSM-5 molecular sieve:

[0058] Weigh 5.0gZn(NO 3 ) 2 ·6H 2 O was dissolved in 20 mL of deionized water to make a solution, and then 20 g of hydrogen-type ZSM-5 molecular sieve (produced by Shanghai Zhuoyue Chemical Technology Co., Ltd.) with a silicon-aluminum ratio of 30 was added to the solution, and soaked at room temperature for 10 hours. The impregnated hydrogen ZSM-5 molecular sieve was dried at 120° C. and then calcined at 550° C. for 5 hours to obtain the hydrogen ZSM-5 molecular sieve loaded with Zn element.

[0059] (2) Modification of hydrogen mordenite:

[0060] Weigh 10.0g of a hydrogen-type mordenite (produced by Shanghai Fuxu Molecular Sieve Co., Ltd.) sample with a silicon-aluminum ratio of...

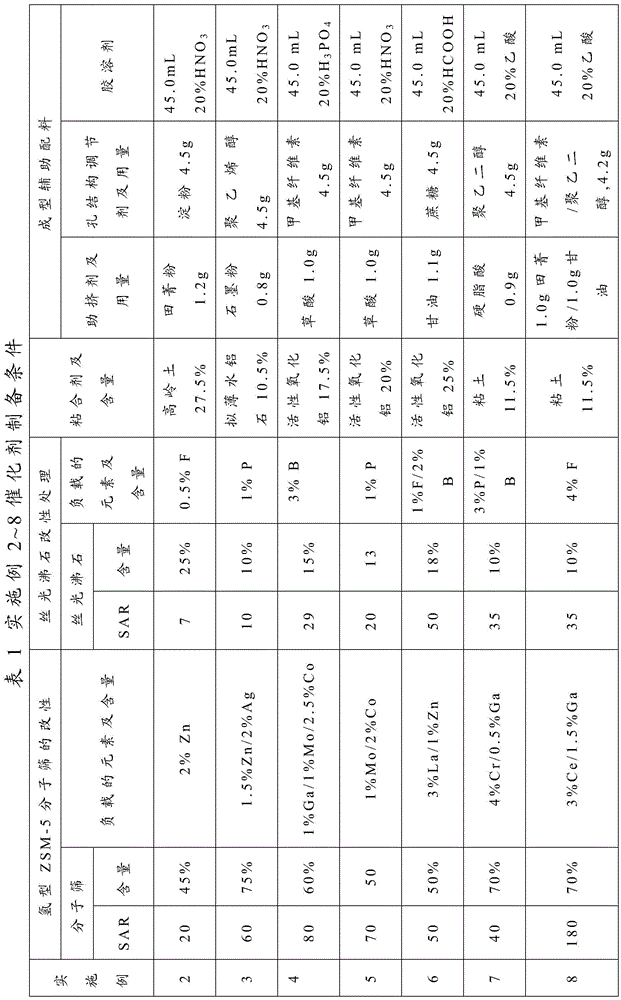

Embodiment 2-8

[0065] Referring to Example 1, molecular sieve catalysts with different components for methanol conversion to aromatics were prepared. The raw materials and some conditions for the preparation of the molecular sieve catalysts of Examples 2-8 are shown in Table 1. In addition, in the modification step of hydrogen-type mordenite, the gas introduced is H with a volume ratio of 30 / 70 2 O / N 2 Mixed gas, and NH is used accordingly 4 F. Ammonium phosphate and ammonium borate; and in the calcining step of the molecular sieve catalyst, after extruding, drying at 100° C., and calcining at 600° C. for 5 hours to obtain the target catalyst.

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com