A kind of copper-silver alloy nano sheet and preparation method thereof

A copper-silver alloy and nanosheet technology, applied in nanotechnology and other directions, can solve the problems of silver homogeneous nucleation, simple preparation process, fast reaction speed, etc., and achieve green and mild reaction conditions, good dispersibility, and high monodispersity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 0.24g of 100nm spherical copper particles into 50ml of ethylene glycol, add 1.95g of polyethylene glycol-2000, stir evenly and heat to 100°C to obtain solution a; add 0.11g of silver nitrate to 10ml of ethanol, and ultrasonically obtain at room temperature Solution b: add solution b to solution a, continue to stir for 120 minutes, then cool to room temperature, centrifuge and wash 4 times with 8000r / min deionized water, take the precipitate and dry it at room temperature for 6 hours under the condition that the vacuum degree is less than 0.01MPa to obtain copper-silver alloy material .

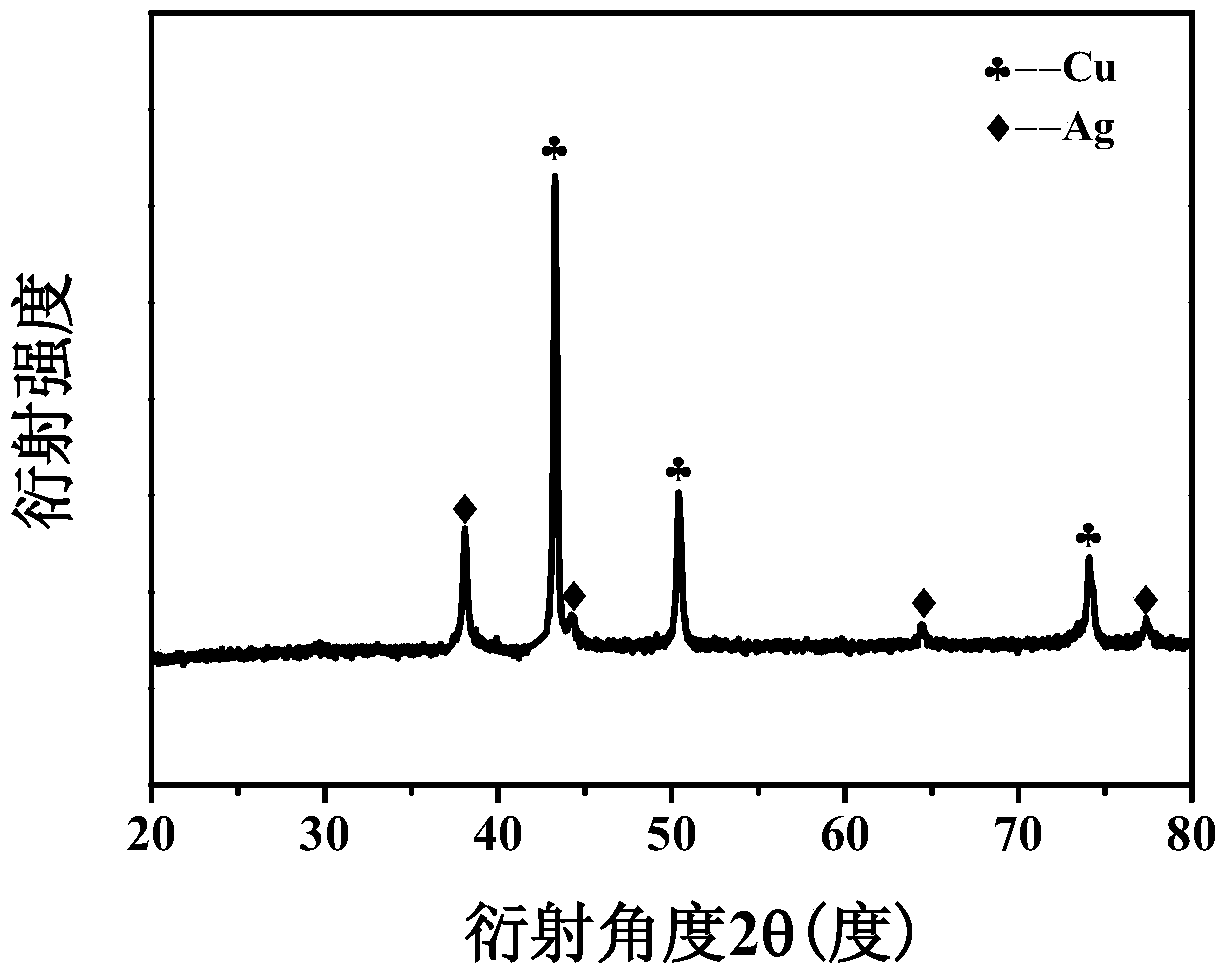

[0027] Get the above-mentioned obtained nanomaterial, adopt X-ray diffractometer (XRD) to carry out phase spectrum analysis to it, adopt field emission scanning electron microscope (SEM) to observe the morphology of particle, the result is as follows figure 1 and figure 2 shown. from figure 1 The characteristic peaks of metal copper and silver can be seen in , without any chara...

Embodiment 2

[0029] Add 0.67g of 400nm spherical copper particles into 100ml of glycerol, add 5.45g of polyvinylpyrrolidone, stir evenly and heat to 120°C to obtain solution a; add 1.22g of silver nitrate to 18ml of water, and ultrasonically obtain solution b at room temperature; Add solution b into solution a, continue to stir for 180 min, then cool to room temperature, centrifuge and wash 4 times with 5000 r / min deionized water, take the precipitate and dry it at room temperature for 8 h under the condition of vacuum degree less than 0.01 MPa to obtain copper-silver alloy material.

[0030] The XRD pattern and the SEM pattern of the prepared copper-silver alloy nanosheet are similar to those in Example 1, showing that the phase of the nano-copper is metallic copper and silver, without other impurities; the particle size is uniform, good dispersion, no obvious reunion phenomenon.

Embodiment 3

[0032] Add 0.08g of 50nm spherical copper particles into 50ml of diethylene glycol, add 0.58g of polyvinyl alcohol, stir evenly and heat to 50°C to obtain solution a; add 0.25g of silver nitrate to 10ml of water, and ultrasonically obtain the solution at room temperature b; add solution b to solution a, continue to stir for 300 minutes, then cool to room temperature, centrifuge and wash 4 times with 3000r / min deionized water, take the precipitate and dry it at room temperature for 12 hours under the condition of vacuum degree less than 0.01MPa to obtain copper-silver alloy material.

[0033] The XRD pattern and the SEM pattern of the prepared copper-silver alloy nanosheet are similar to those in Example 1, showing that the phase of the nano-copper is metallic copper and silver, without other impurities; the particle size is uniform, good dispersion, no obvious reunion phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com