Preparation method of Fe3C nanowire filled and nitrogen doped carbon nanotube composite with high specific surface area

A technology of nitrogen-doped carbon and composite materials, applied in the direction of nanotechnology, etc., can solve the problems of being unsuitable for large-scale industrial production, high impurity content, and low specific surface area, and achieve low cost, high specific surface area, and low raw material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 3g melamine, 1.1gFeCl 3 ·6H 2 O and 3gZnCl 2 , 500rpm mechanical stirring for 3h; the mixture was transferred to a ceramic crucible, placed in a tube furnace, under N 2 Under protection, pre-carbonize at 500°C for 1 hour, then carbonize at 900°C for 2 hours; soak the obtained carbon material in 3M HCl solution for 6 hours, filter, and dry at 120°C to obtain Fe 3 C nanowires filled N-doped carbon nanotube composites.

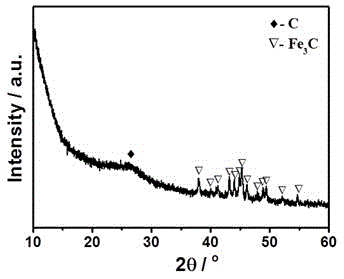

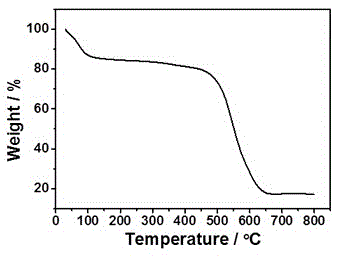

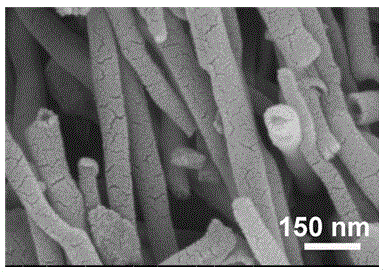

[0025] The XRD diffraction pattern of the material ( figure 1 ) indicates that the composite material consists of carbon and Fe 3 C composition, according to the thermogravimetric curve ( figure 2 ) to get the composite material Fe 3 C content is 13.2wt%; SEM ( image 3 ) and TEM images ( Figure 4 ) show that Fe 3 C nanowires filled in carbon nanotube composites. by N 2 Adsorption-desorption equilibrium curve ( Figure 6 ), the calculated specific surface area of the composite material is 1026.26m 2 g -1 .

Embodiment 2

[0027] Weigh 3g melamine, 1.6gFeCl 3 ·6H 2 O and 3gZnCl 2 , 500rpm mechanical stirring for 2h; the mixture was transferred to a ceramic crucible, placed in a tube furnace, under N 2 Under protection, pre-carbonize at 400°C for 3h, and then carbonize at 800°C for 2h; soak the obtained carbon material in 2M HCl solution for 5h, filter, and dry at 100°C to obtain Fe 3 C nanowires filled N-doped carbon nanotube composites.

[0028] According to TGA and N 2 Adsorption-desorption curve, the calculated composite material Fe 3 The C content is 14.8wt%, and the specific surface area is 639.42m 2 g -1 .

Embodiment 3

[0030] Weigh 3g melamine, 3.24gFeCl 3 ·6H 2 O and 3gZnCl 2 , 500rpm mechanical stirring for 1h; the mixture was transferred to a ceramic crucible, placed in a tube furnace, under N 2 Under protection, pre-carbonize at 500°C for 2 hours, and then heat up to 700°C for carbonization for 3 hours; soak the obtained carbon material in 1M HCl solution for 10 hours, filter, and dry at 100°C to obtain Fe 3 C nanowires filled N-doped carbon nanotube composites.

[0031] According to TGA and N 2 Adsorption-desorption curve, the calculated composite material Fe 3 The C content is 16.5wt%, and the specific surface area is 411.89m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com