Sewage composite catalytic oxidation treatment method

A technology of catalytic oxidation and treatment method, applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high energy consumption, low degradation efficiency, large secondary pollution, etc. Low consumption, high oxidation potential and small secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

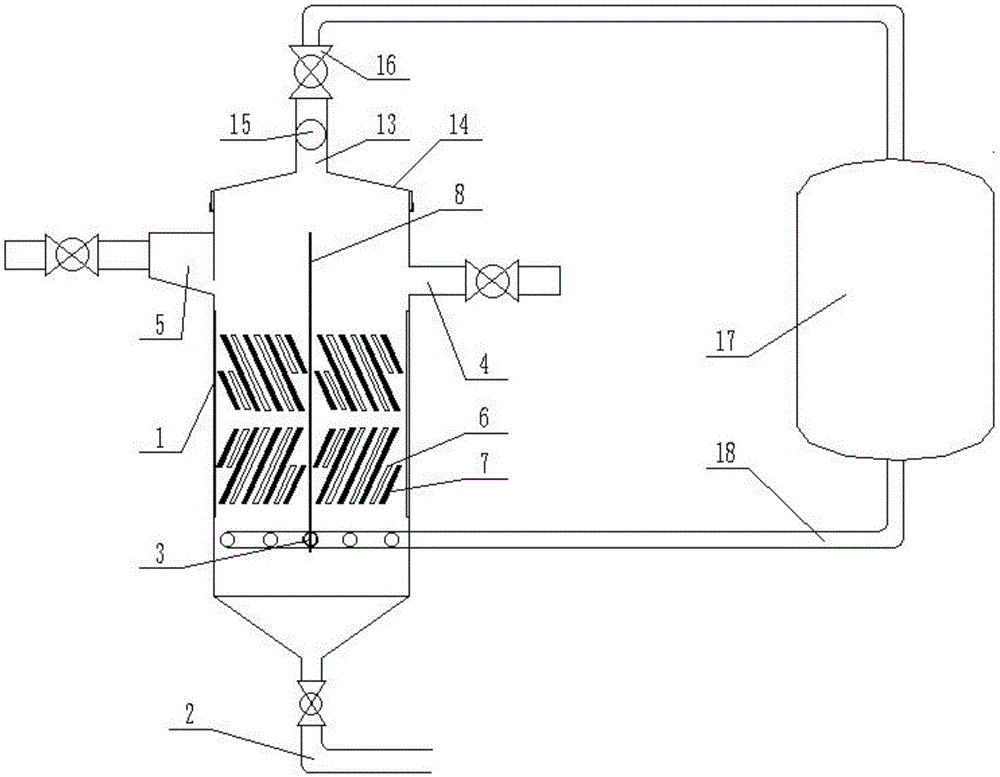

[0028] Such as figure 1 As shown, it is a structural schematic diagram of the catalytic oxidation device adopted in the present invention, including a device body 1, a solid phase outlet 2 and a gas phase inlet 3 are provided at the bottom of the device body 1, a liquid phase inlet 4 is provided on the right side of the device body 1 top, and a liquid phase inlet 4 is provided on the left side of the device body 1. A liquid phase outlet 5 is provided on the side, and a baffle plate 8 parallel to the axial direction of the device body 1 is provided in the device body 1. Both sides of the baffle plate 8 include four light source plates 6 and five catalyst plates 7, The light source plate 6 and the catalyst plate 7 are arranged adjacent to each other in parallel, and form an angle of 40° with the axial direction of the device body 1 . The light source plate 6 is provided with a light source, and the light source includes a visible light source and an ultraviolet light source. The...

Embodiment 2

[0033] Embodiment 2 is identical with embodiment 1, and difference is that device internal pressure is 0.1Mpa, and the ratio of ozone inlet and sewage flow is 1:1; The ratio of the hydraulic retention time of ozone and the hydraulic retention time of sewage is 3: 1. Both sides of the deflection baffle 8 include two light source plates 6 and two catalyst plates 7 adjacent to each other and arranged in parallel in sequence, and the axial direction of the light source plate 6 and catalyst plate 7 and the device body 1 are both clamped at 65° Angle, the specific arrangement sequence is: ultraviolet light source plate, catalyst plate, visible light source plate, catalyst plate; the catalyst plate is filled with catalyst particles, and the catalyst is a mixture of nickel and iron.

Embodiment 3

[0035] Embodiment 3 is identical with embodiment 1, and difference is that device internal pressure is 0.3Mpa, and the ratio of ozone feed rate and sewage flow is 5:1, and the ratio of the hydraulic retention time of ozone and the hydraulic retention time of sewage is 0.5: 1. Both sides of the deflection baffle 8 include four light source plates 6 and three catalyst plates 7 that are adjacent to each other and arranged in parallel. Angle, the specific order of arrangement is: visible light source plate, catalyst plate, ultraviolet light source plate, catalyst plate, visible light source plate, catalyst plate, ultraviolet light source plate; the surface of the catalyst plate is electroplated with a catalyst, and the catalyst is zinc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com