A method for reducing cod of tricyclazole pesticide wastewater

A pesticide wastewater and tricyclazole technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of low Fenton oxidation degradation rate, reduce concentration, improve efficiency, and avoid disposal costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

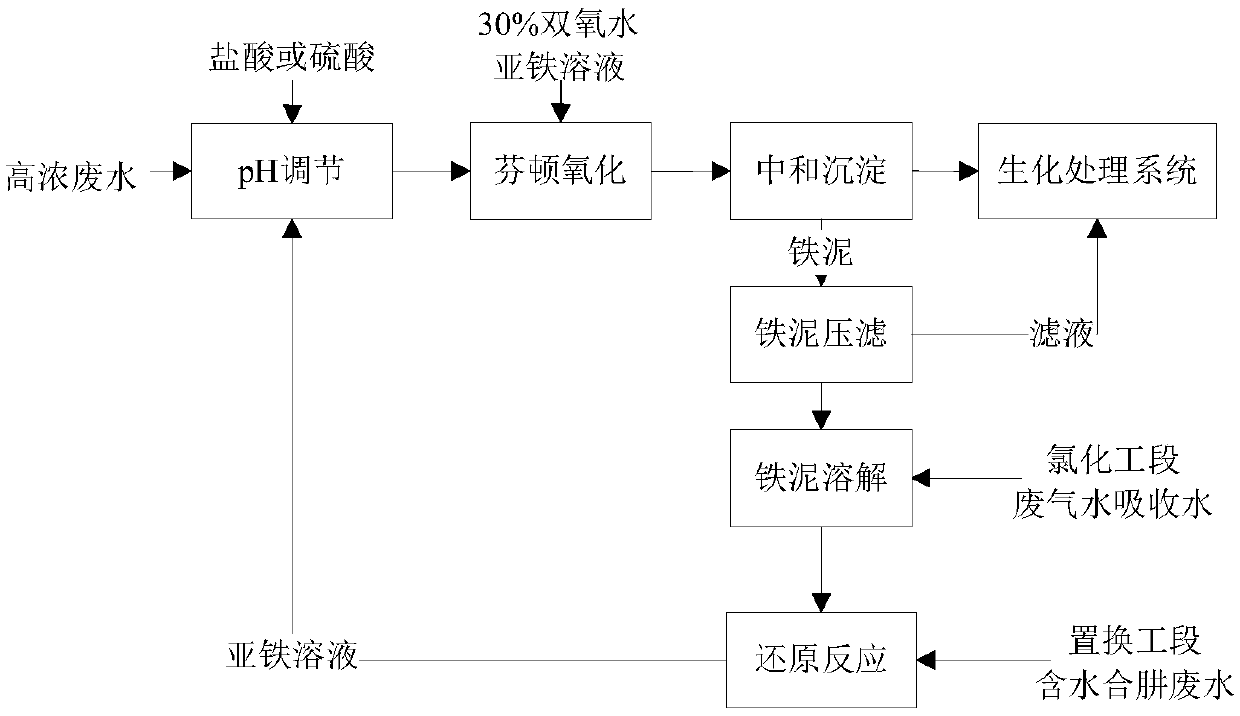

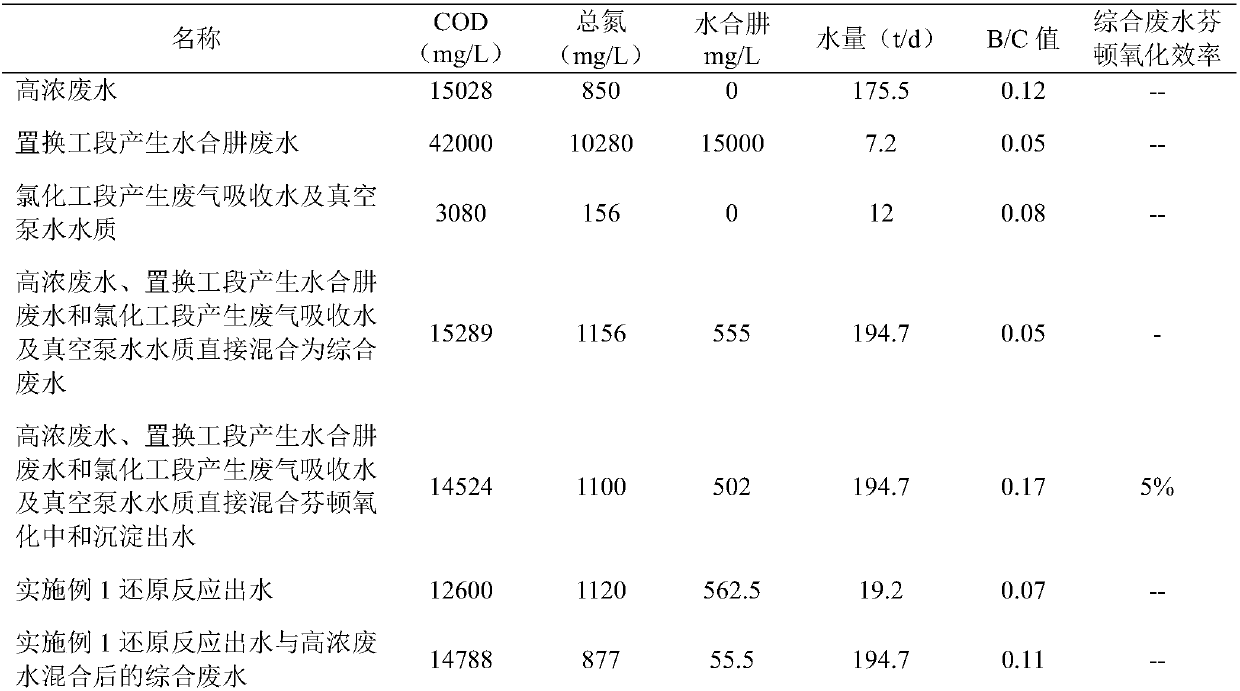

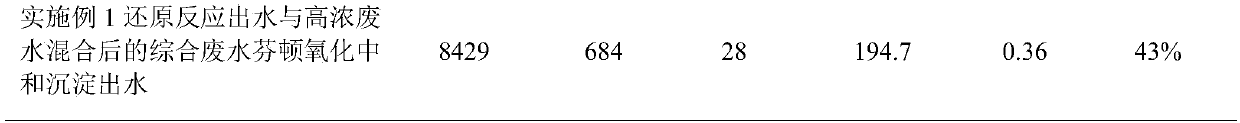

[0037] Such as figure 1 As shown, a process wastewater producing tricyclazole in Jiangsu, among which, the water quality of high-concentration wastewater (containing high-salt wastewater condensate) is: CODcr15028mg / L, total nitrogen 850mg / L, water volume 175.5t / d; replacement section produces hydrazine hydrate wastewater Water quality: CODcr42000mg / L, total nitrogen 10280mg / L, hydrazine hydrate 15000mg / L, water volume 7.2t / d; waste gas absorption water and vacuum pump water produced in the chlorination section Water quality: CODcr3080mg / L, total nitrogen 156mg / L, hydrochloric acid mass concentration 10 %, the amount of water is 12t / d. combined with figure 1 , present embodiment proposes a kind of method that reduces tricyclazole wastewater COD, and its steps are as follows:

[0038] (1) When running for the first time, adjust the pH of tricyclazole high-concentration wastewater to 5 with hydrochloric acid, add hydrogen peroxide with a mass fraction of 30% and a ferrous sulf...

Embodiment 2

[0047] Such as figure 1 As shown, a process wastewater producing tricyclazole in Jiangsu, among them, the water quality of high-concentration wastewater (including high-salt wastewater condensate): CODcr12650mg / L, total nitrogen 627mg / L, water volume 175.5t / d; replacement section produces hydrazine hydrate wastewater Water quality: CODcr38500mg / L, total nitrogen 8970mg / L, hydrazine hydrate 13068mg / L, water volume 7.2t / d; water quality of waste gas absorption water and vacuum pump water produced in chlorination section: CODcr2980mg / L, total nitrogen 120mg / L, 12t / d. combined with figure 1 , present embodiment proposes a kind of method that reduces tricyclazole wastewater COD, and its steps are:

[0048] (1) When running for the first time, adjust the pH of tricyclazole high-concentration wastewater to 3 with hydrochloric acid, add hydrogen peroxide with a mass fraction of 50% and a ferrous sulfate solution with a mass concentration of 30%, and aerate and stir for 150 minutes. ...

Embodiment 3

[0056] Such as figure 1 As shown, a process wastewater producing tricyclazole in Jiangsu, among which, the water quality of high-concentration wastewater (containing high-salt wastewater condensate) is: CODcr11280mg / L, total nitrogen 597mg / L, and water volume 175.5t / d; the replacement section produces hydrazine hydrate wastewater Water quality: CODcr35600mg / L, total nitrogen 8125mg / L, hydrazine hydrate 12560mg / L, water volume 7.2t / d; water quality of waste gas absorption water and vacuum pump water produced in chlorination section: CODcr3200mg / L, total nitrogen 160mg / L, 12t / d. combined with figure 1 , present embodiment proposes a kind of method that reduces tricyclazole wastewater COD, and its steps are:

[0057] (1) When running for the first time, adjust the pH of tricyclazole high-concentration wastewater to 2 with hydrochloric acid, add hydrogen peroxide with a mass fraction of 40% and a ferrous sulfate solution with a mass concentration of 25%, and aerate and stir for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com