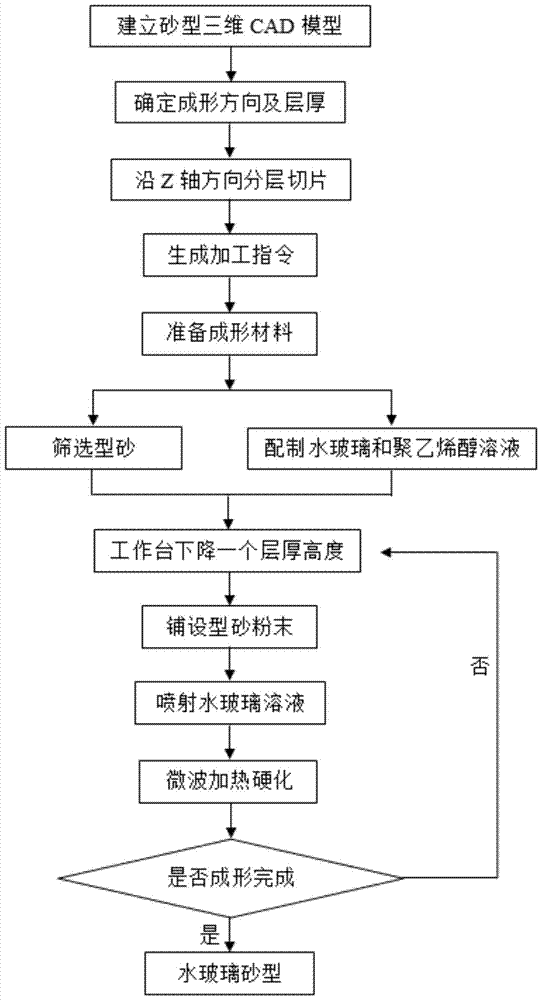

A rapid forming method of water glass sand mold

A technology of water glass sand and water glass, which is applied in the direction of casting mold components, cores, casting molds, etc., can solve the problems of difficult process, limitation of difficulty, and influence on the accuracy of forming layer thickness, so as to ensure the density and smooth surface Accuracy, improving Z-axis delamination accuracy, and reducing the effect of surface pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

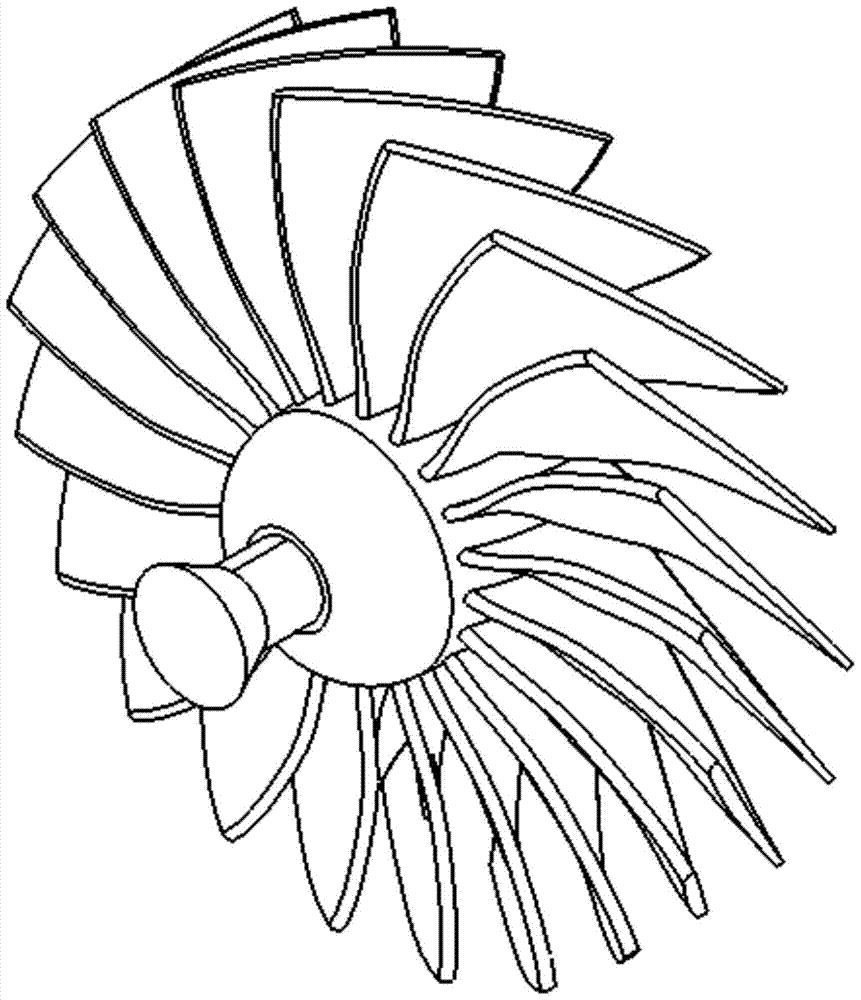

[0046] Utilize the method of the present invention to form a pearl sand core blade of 70 mesh to 140 mesh, the blade height is 78.5mm, and the maximum outer ring diameter is 170mm.

[0047] The specific process is as follows:

[0048] (1) According to the outline dimension of the water glass sand core to be formed, establish the three-dimensional solid model of the water glass sand core to be formed by pro / E software, take the Z axis as the forming direction, and set the forming layer thickness as 0.18mm.

[0049] (2) Lay a layer of molding sand material first, and the powder spreading speed when laying a layer of molding sand material is 0.4m / s. The spray head is then used to spray a binder on the surface of the molding sand material to form the outline pattern of the current layer, and the binder is a mixed solution of water glass and polyvinyl alcohol. In the binder, the addition of polyvinyl alcohol is 1.5% of the water glass quality. The viscosity of the binder is 8mPa·...

Embodiment 2

[0054] Utilize the method of the present invention to form a zircon sand core blade of 140 mesh to 240 mesh, the blade height is 78.5 mm, and the maximum outer ring diameter is 170 mm.

[0055] The specific process is as follows:

[0056] (1) According to the outline dimension of the water glass sand core to be formed, establish the three-dimensional solid model of the water glass sand core to be formed by pro / E software, take the Z axis as the forming direction, and set the forming layer thickness as 0.12mm.

[0057] (2) Lay a layer of molding sand material first, and the powder spreading speed when laying a layer of molding sand material is 0.1m / s. The spray head is then used to spray a binder on the surface of the molding sand material to form the outline pattern of the current layer, and the binder is a mixed solution of water glass and polyvinyl alcohol. In the binder, the addition of polyvinyl alcohol is 4% of the water glass quality. The viscosity of the binder is les...

Embodiment 3

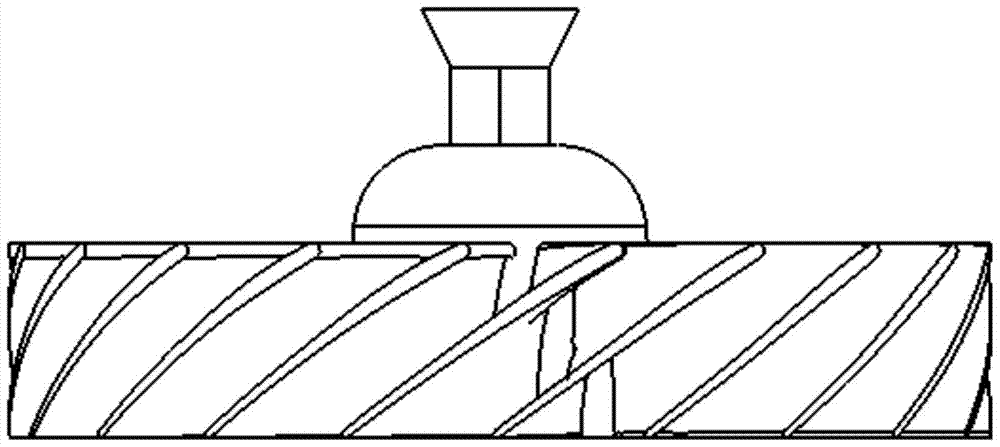

[0062] Utilize the method of the present invention to form the sand mold of a spur gear, the gear height is 50mm, and the maximum outer ring diameter is 300mm. image 3 It is a schematic diagram of the shape and structure of the spur gear in the embodiment of the present invention.

[0063] The specific process is as follows:

[0064] (1) According to the properties of the spur gear and the forming process conditions, design and establish the three-dimensional solid model of the gear water glass sand mold through the pro / E software, the height is 800mm, the length and width are 340mm, and the Z axis is the forming direction, set The forming layer thickness is 0.25mm.

[0065] (2) Lay a layer of molding sand material first, and the powder spreading speed when laying a layer of molding sand material is 0.3m / s. The spray head is then used to spray a binder on the surface of the molding sand material to form the outline pattern of the current layer, and the binder is a mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com