Ultra-high-density single-walled carbon nanotube horizontal array and controllable preparation method thereof

A single-walled carbon nanotube, ultra-high density technology, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, oriented carbon nanotubes, etc. The density does not meet the requirements and other problems, to achieve the effect of controllable preparation, simple sample preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

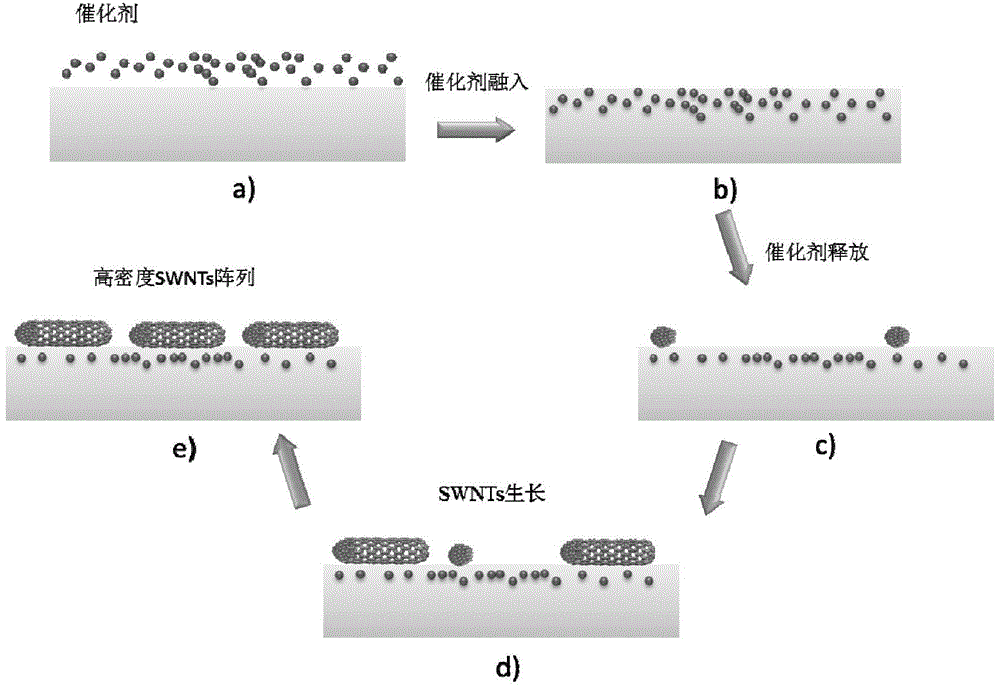

[0052] Example 1, Growth of ultra-high-density single-walled carbon nanotube horizontal arrays

[0053] 1) Pretreatment of single crystal growth substrate;

[0054] Select the a-face α-alumina single crystal substrate as the substrate for carbon nanotube growth, cut it into a size of 4 mm × 6 mm, the side with a length of 4 mm is parallel to the [0001] direction, and the side with a length of 6 mm is parallel to the [1-100] direction. This substrate is pretreated as follows:

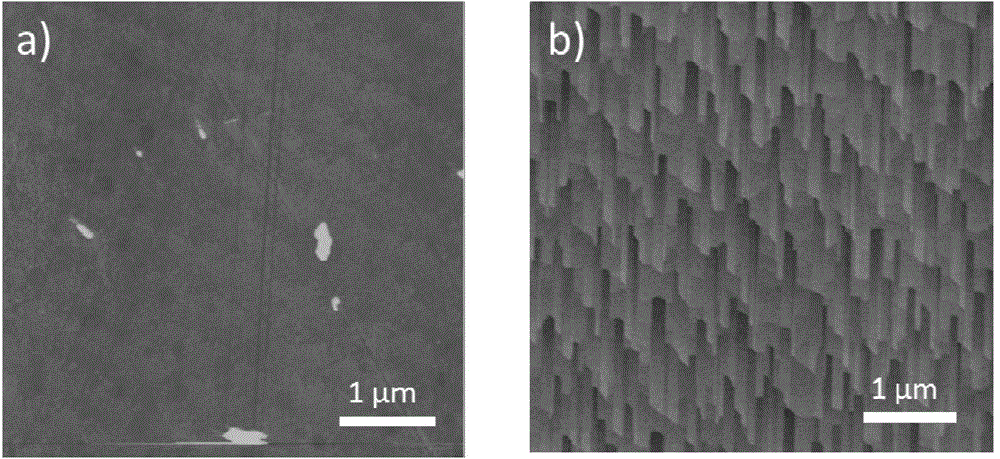

[0055] Sequentially ultrasonic cleaning in secondary water, acetone, ethanol and secondary water for 10 minutes, and then drying with high-purity nitrogen, the surface morphology is as follows: figure 2 a) as shown.

[0056] Put the cleaned substrate into the muffle furnace, raise the temperature from room temperature to 1100°C within 2 hours, keep the temperature at 1100°C for 8 hours, then cool down to 300°C within 10 hours, and then naturally cool down to room temperature to obtain the pretreated ...

Embodiment 2

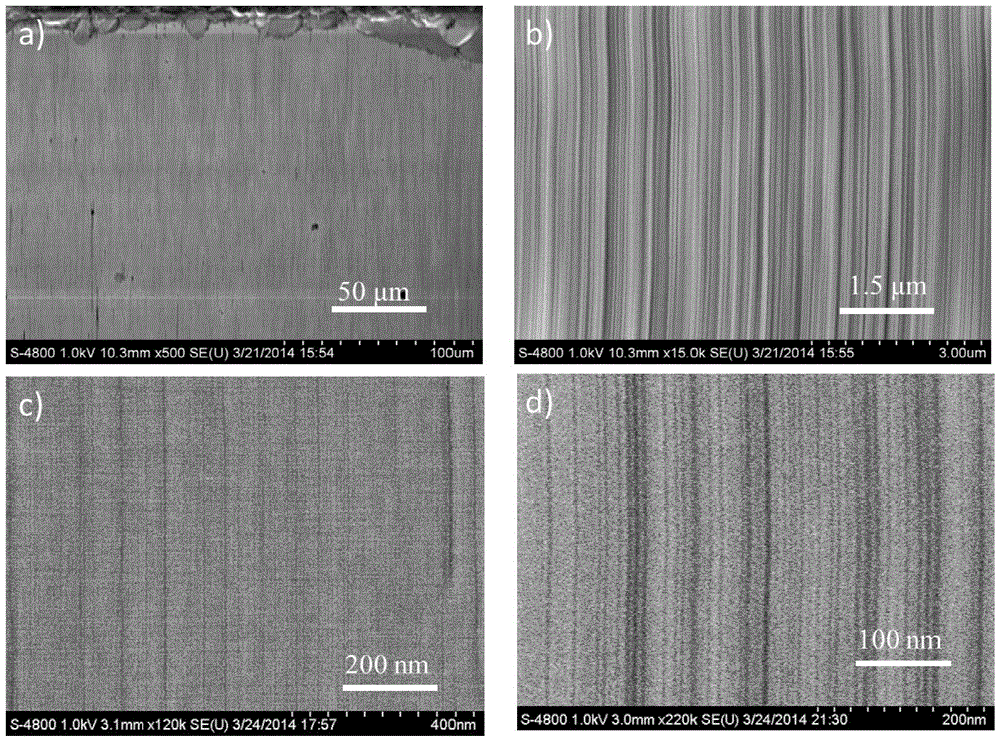

[0068] Embodiment 2, growing ultra-high-density single-walled carbon nanotube horizontal arrays;

[0069] Step 1) is the same as embodiment 1 step 1;

[0070] Step 2) and 3) Fe(OH) used in embodiment 1 3 / EtOH solution was replaced by (NH 4 ) 6 Mo 7 o 4 The concentration is 0.01mmol / L (NH 4 ) 6 Mo 7 o 4 / EtOH solution, and then according to step 3) of Example 1, spin-coat on the a-face α-alumina single crystal substrate, that is, the surface of the a-face α-alumina single-crystal substrate is loaded with a Mo-containing catalyst.

[0071] 4) Annealing

[0072] Place the substrate in a muffle furnace, anneal at high temperature in air, rise from room temperature to 1000°C within 1.5 hours, keep the temperature at 1000°C for 16 hours, then cool down to 300°C within 10 hours, and then naturally cool down to room temperature to complete the annealing step;

[0073] 5) Directional growth of single-walled carbon nanotubes by chemical vapor deposition:

[0074] Place the ...

Embodiment 3

[0076] Embodiment 3, the mechanism analysis of the preparation method of ultra-high-density single-walled carbon nanotube horizontal array;

[0077] 1) Analysis and verification of the fusion mechanism in the preparation method of ultra-high-density single-walled carbon nanotube horizontal arrays;

[0078] The single crystal growth substrate after the annealing of step 4) in embodiment 1 is carried out XPS depth analysis, as Figure 5 As shown, there is Fe element found on the surface of the alumina single crystal substrate. Obviously, the Fe catalyst can indeed enter the alumina single crystal substrate and store it through the above annealing method.

[0079] 2) Analysis and verification of the release mechanism in the preparation method of ultra-high-density single-walled carbon nanotube horizontal arrays;

[0080] The single crystal growth substrate obtained in step 4) of Example 1 was placed in a tube furnace for hydrogen annealing treatment, the hydrogen flow rate was 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com